Press-bending laser composite forming method

A composite forming and laser technology, applied in the field of sheet metal structural parts, can solve the problems of leaving damage on the surface of the workpiece, difficult to manufacture automation, etc., and achieve the effect of helping forming, overcoming damage or even destruction of formed parts, and reducing deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

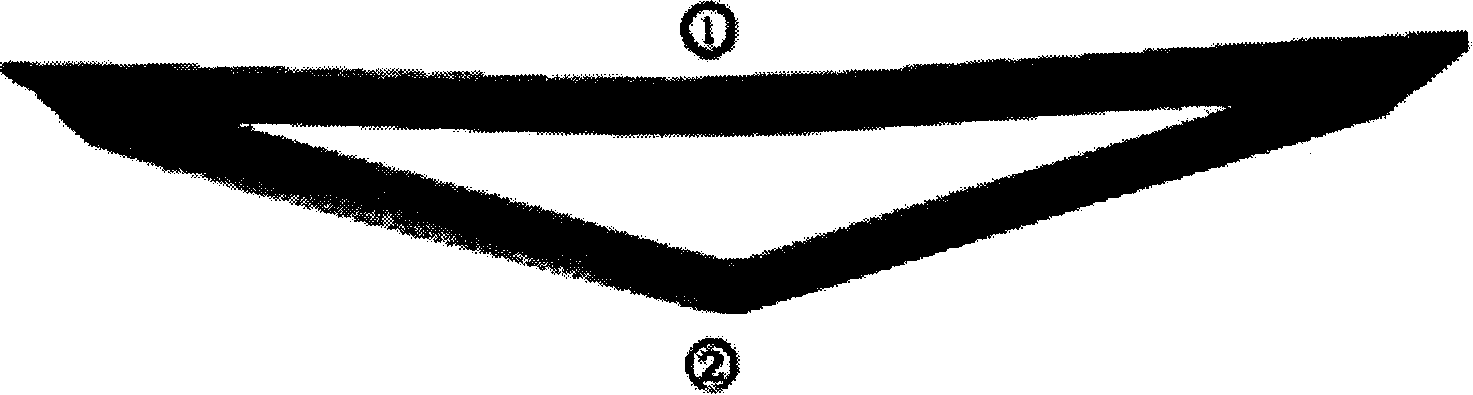

Image

Examples

Embodiment Construction

[0014] The present invention can be divided into two working schemes of forming and fine adjustment. The so-called forming scheme is to input laser energy to the difficult-to-deform part of the part while forming by bending (rolling). When this method is used for forming, the thermal energy transformed by the laser energy can not only reduce the deformation resistance of the material in the laser action area, but also assist the forming of the part through the non-uniform thermal stress field established in the thickness direction of the part, so the above-mentioned formed parts can be significantly improved. The amount of bending forming, forming efficiency and forming accuracy. Hard-to-deform parts can be obtained by computer simulation of formed parts. The so-called fine-tuning scheme is to input laser energy to the corresponding elastic internal energy concentration area for parts formed by press bending or the above-mentioned press-bending laser composite method but whos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com