Drawing forming device and method of non-axisymmetric piece made of difficult-to-deform material

A non-axisymmetric, hard-to-deform technology, used in forming tools, presses, metal processing equipment, etc., to achieve the effect of increasing drawing height, improving plastic fluidity, and reducing structural and operational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

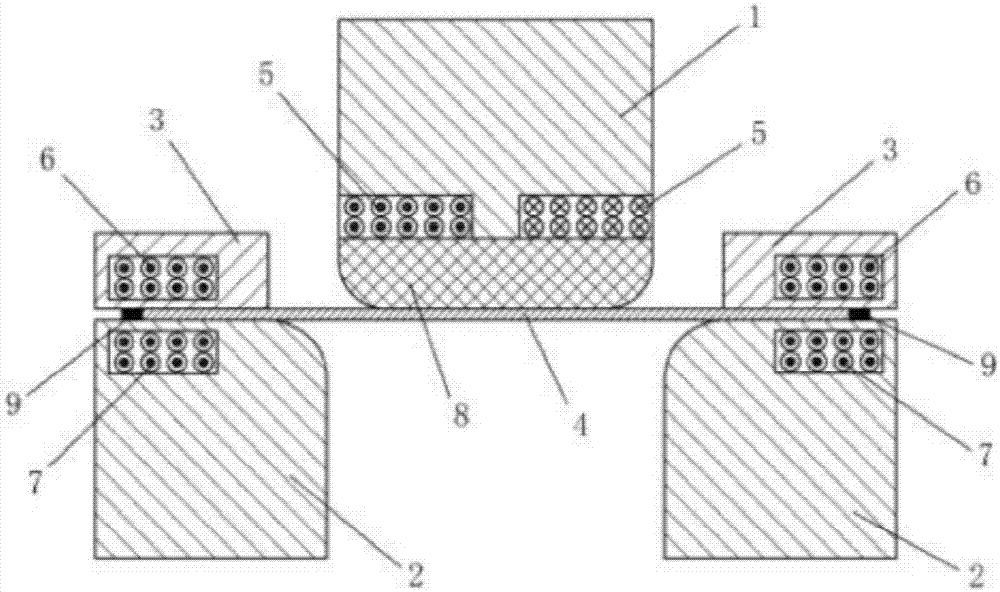

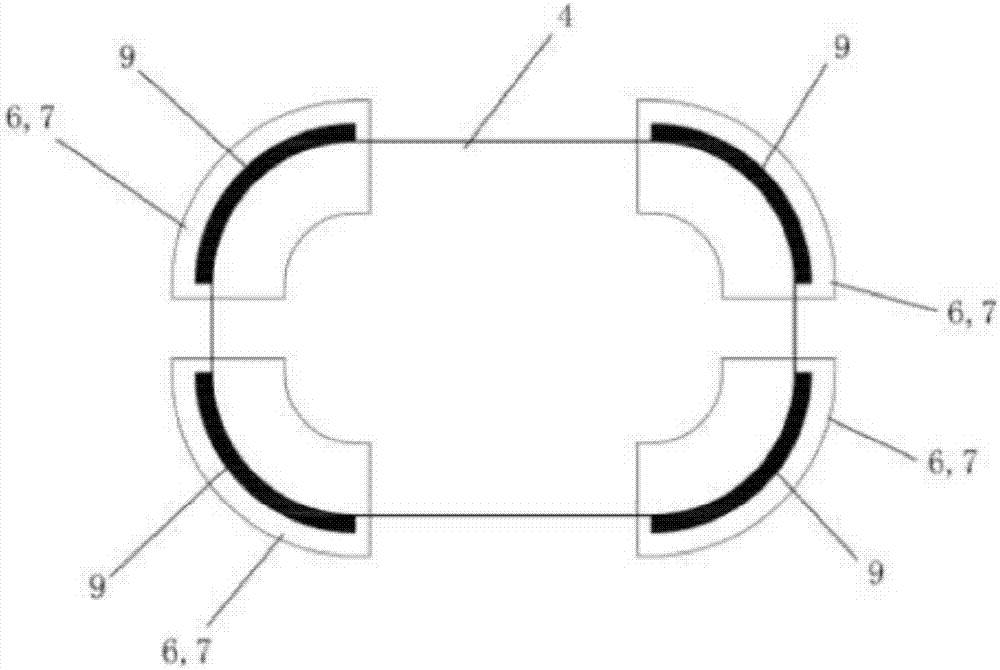

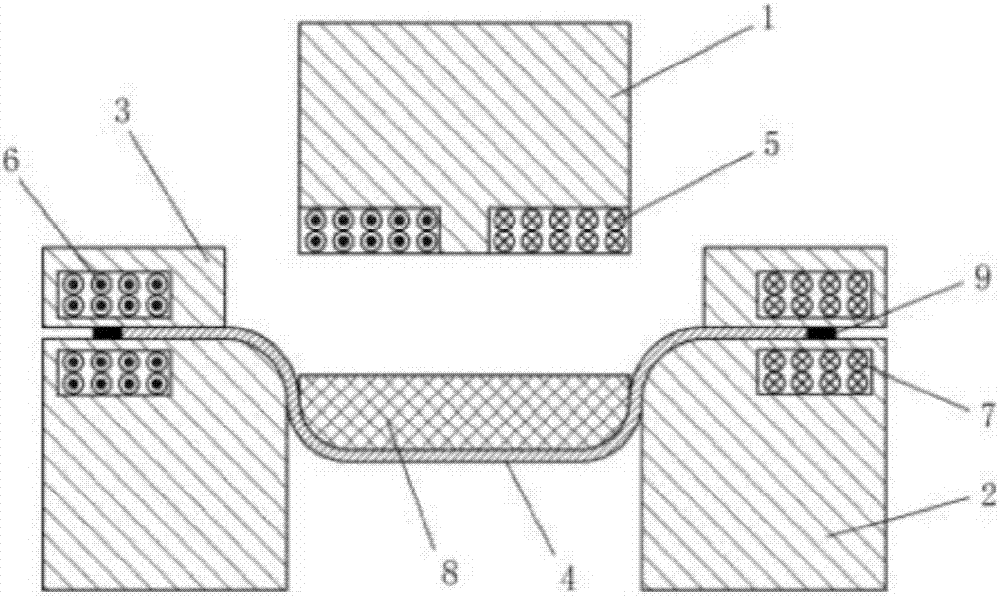

[0044] Such as Figure 1 to Figure 8 As shown, a deep drawing device for a non-axisymmetric piece of difficult-to-deform material of the present invention includes a punch 1 , a die 2 and a blank holder 3 . Wherein, the blank holder 3 is movably arranged above the die 2 , and the blank holder 3 is used to clamp the blank 4 to be formed between the blank holder 3 and the die 2 . An axial drawing coil 5 is arranged at the bottom of the punch 1, an upper groove and a lower groove are respectively arranged on the die 2 and the blank holder 3, and an upper radial side pushing coil is embedded in the upper groove 6. A lower radial side push coil 7 is embedded in the lower groove. The deep drawing device also includes a high-conductivity driving punch 8 and a plurality of high-conductivity driving bars 9 . The high-conductivity driving punch 8 is placed under the punch 1 , so that the upper surface of the high-conductivity driving punch 8 is in contact with the lower surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com