Auxiliary incremental forming device heating metal plate by using electrical discharges

A technology of incremental forming and sheet metal, which is applied in the field of mechanical manufacturing and processing, and can solve problems such as wrinkling, cracking, and uneven metal flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

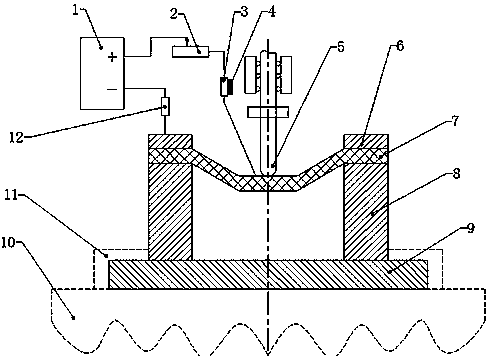

[0006] The bracket 8 is fixed on the bottom plate 9 and fixed on the machine tool workbench 10 through the clamping mechanism 11, the plate 7 is pressed together with the bracket 8 through the blank holder 6, and the tool head 5 is connected with the main shaft of the machine tool through the tool holder; One end of the anode 3 and the spark cathode 12 are respectively connected to the positive and negative poles of the power supply 1, and the other ends are kept in contact with the plate 7 and the blank holder 6 respectively; the adjustable resistor 2 is connected in series between the spark anode 3 and the power supply 1 In the circuit, the size of the discharge intensity is changed by adjusting the size of the resistance in the circuit, and the control of the forming temperature is realized; the vibrator 4 is fixed with the EDM anode 3 or the EDM cathode 12, and the Vibration, frequent alternating contact and disconnection between the electric spark anode 3 and the plate 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com