Agitating friction spot welding device and method for dissimilar metal

A technology of friction stirring and dissimilar metals, applied in metal processing equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of high plastic deformation resistance of welding materials, poor welding performance, and low welding quality of spot welding joints, so as to improve plasticity Flow ability, reduce welding pressure, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

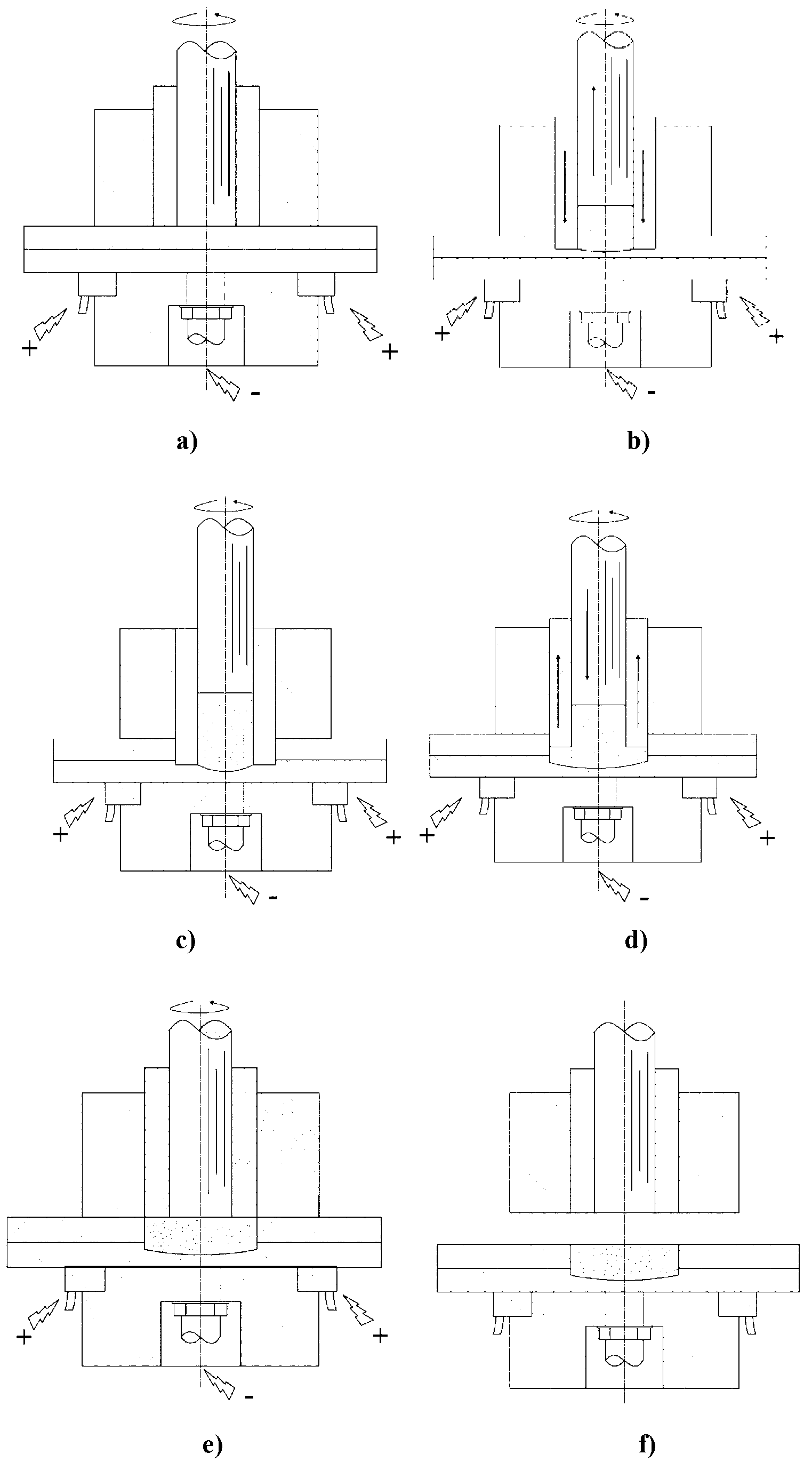

[0020] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

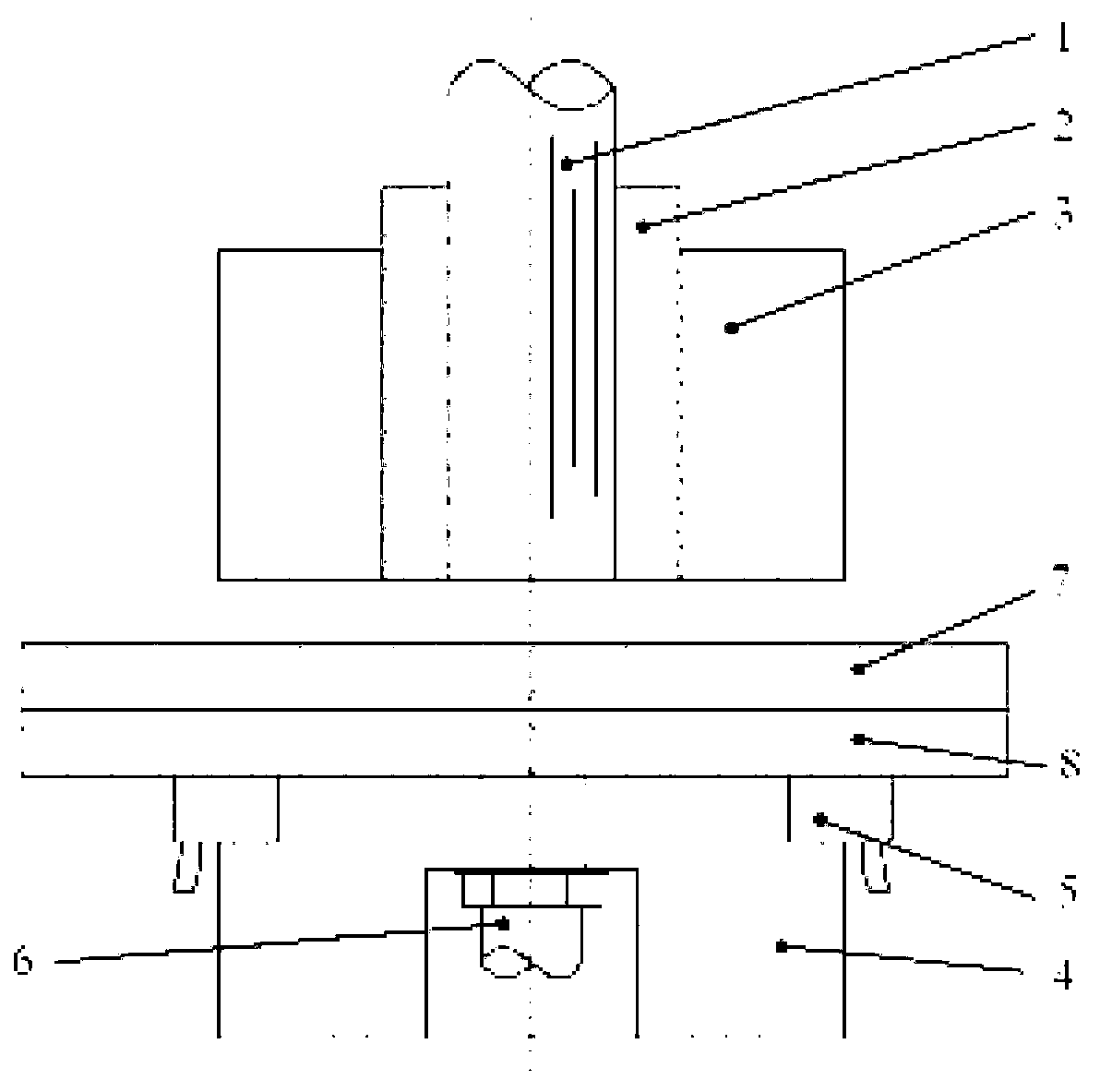

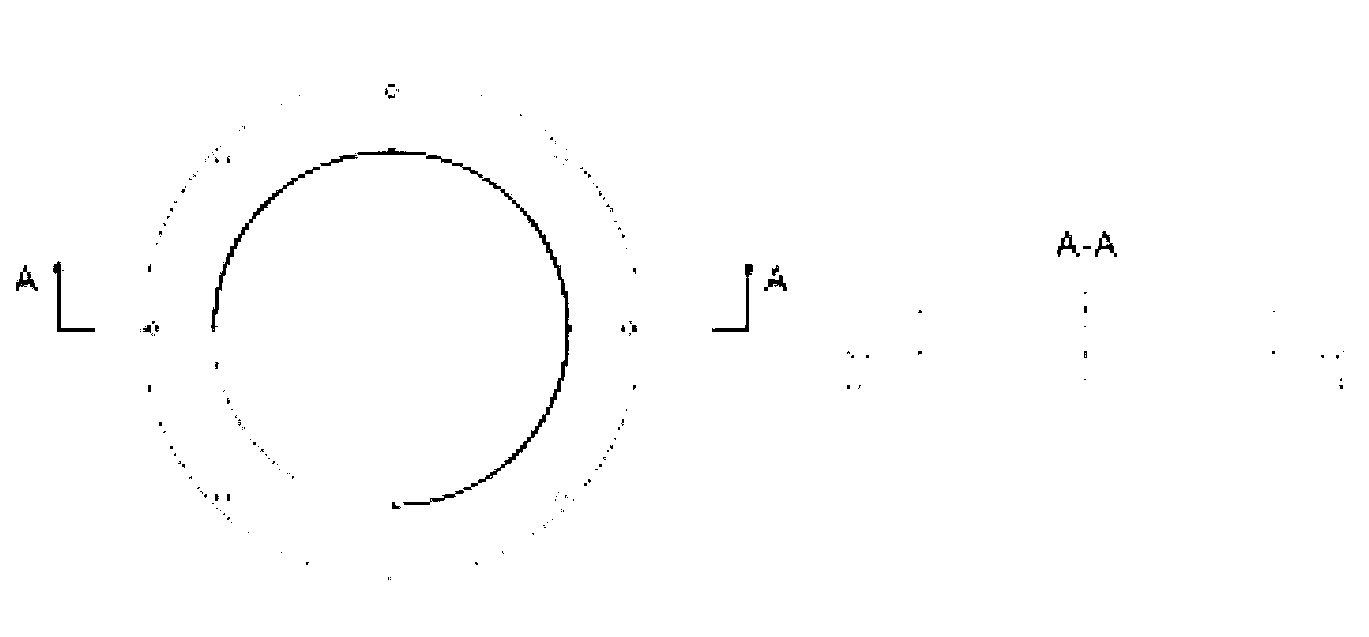

[0021] Such as figure 1 As shown, a dissimilar metal friction stir spot welding device of the present invention includes a stirring sleeve 2, a stirring needle 1 in the stirring sleeve 2, a clamping sleeve 3 clamped outside the stirring sleeve 2, and a welding pad 4 , between the clamping sleeve 3 and the welding pad 4 is a welding workpiece, which is characterized in that an annular brush 5 is arranged on the top of the welding pad 4, and a T-shaped through hole is provided in the center of the welding pad 4, and the installation conductive The rod 6 and the conductive rod 6 are flush with the upper surface of the welding pad 4, and the annular brush 5 and the conductive rod 6 are respectively connected to the positive pole and the negative pole of the controllable DC power supply throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com