Carbonate rock area pulling-resistant anchor rod grouting and drainage device and construction method thereof

A carbonate rock and drainage device technology, applied in protection devices, foundation structure engineering, sheet pile walls, etc., can solve problems such as the difficulty of grouting anti-floating anchor rods, and achieve reduced grouting difficulty, low cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

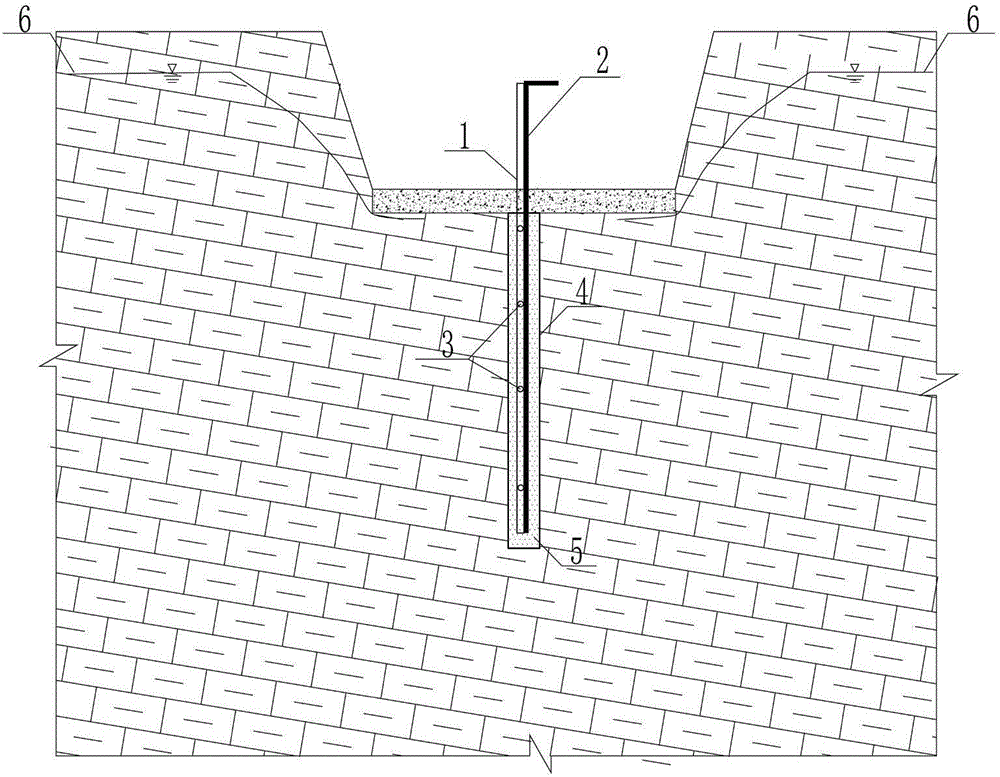

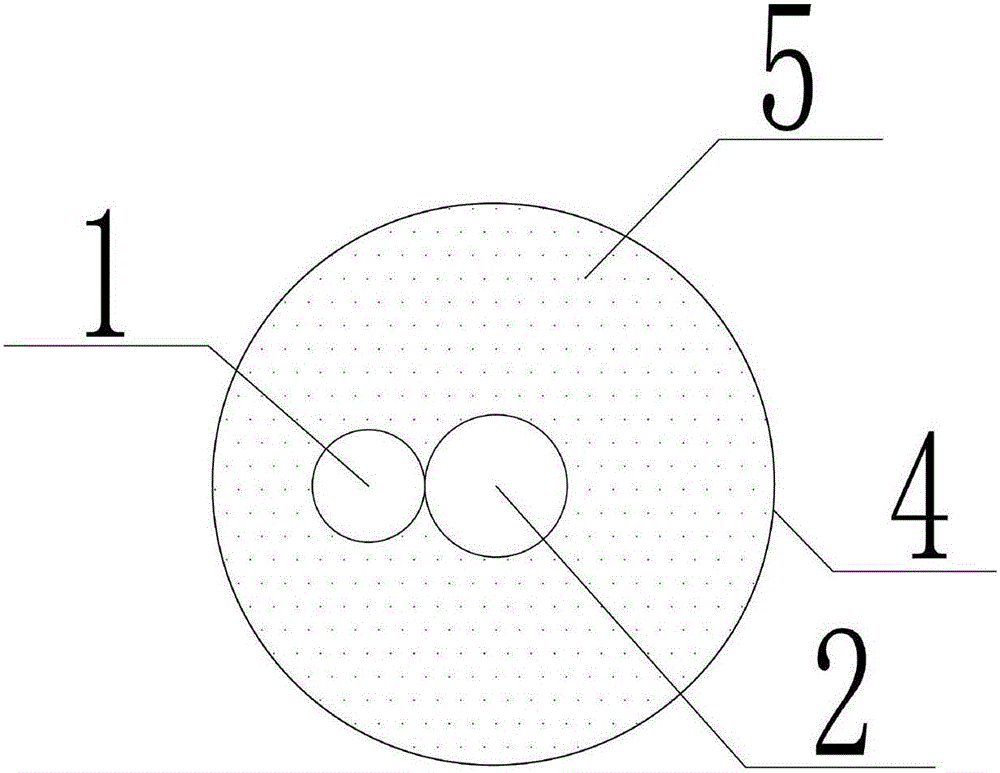

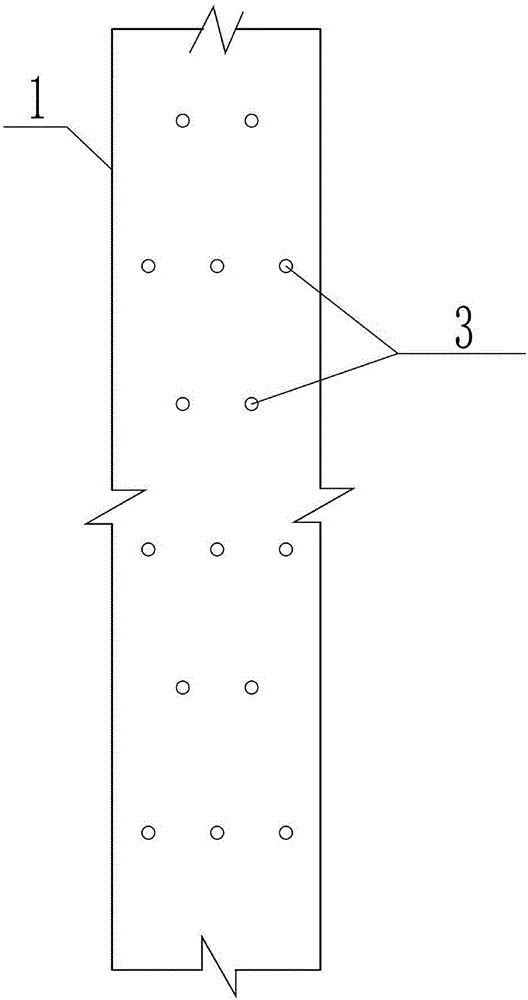

[0020] Embodiment 1: as Figure 1-Figure 3 As shown, a grouting drainage device for anti-lift anchors in carbonate rock areas, including steel pipe 1 and anti-floating anchor 2, anti-floating anchor 2 and steel pipe 1 are fixed side by side by steel wires and extend into the grouting hole 4 Inside, the steel pipe 1 extends into the grouting hole 4 and a section is provided with a sieve hole 3 .

[0021] Preferably, the steel pipe 1 has an outer diameter of 20-40 mm, and the anti-floating anchor rod 2 has a diameter of 28 mm, which can meet the pressure relief requirements.

[0022] Preferably, the above-mentioned sieve holes 3 extend all over the body of a section of steel pipe 1 extending into the grouting holes 4, and the sieve holes 3 have an aperture diameter of 8-10 mm, which can meet the pressure relief requirements and avoid the pressure relief effect caused by the grouting slurry passing through the sieve holes. question.

[0023] Preferably, the above-mentioned siev...

Embodiment 2

[0025] Embodiment 2: A kind of construction method of anti-lift bolt grouting drainage device in carbonate rock area, this method comprises the following steps:

[0026] Step 1, after the confined water level 6 in the foundation pit is pumped below the bottom of the pit, measure and stake out, locate the position of the grouting hole 4, and make a mark;

[0027] Step 2, use drilling equipment to drill the grouting hole 4 mark vertically downwards to the specified depth with a hole diameter of 130mm;

[0028] Step 3, put the 25mm steel pipe 1 tied side by side and the anti-floating anchor rod 2 with a diameter of 28mm into the grouting hole 4;

[0029] Step 4: Carry out high-pressure grouting to the grouting hole 4. After the grouting is completed, the steel pipe is not pulled out, so that it forms an anchor together with the anti-floating anchor rod to jointly resist the pull-out force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com