Abandoned oil-gas pipeline grouting filling device and method

A technology for oil and gas pipelines and filling devices, which is used in soil protection, construction, infrastructure engineering, etc., and can solve the problems of inefficient and low-cost waste oil and gas pipeline grouting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

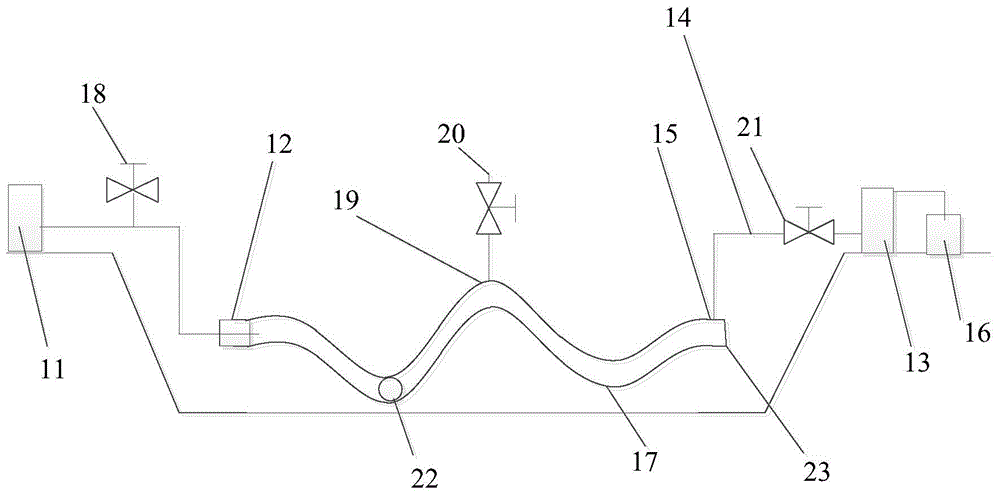

[0035] This embodiment provides a grouting filling device for abandoned oil and gas pipelines, such as figure 1 As shown, the device includes: a grouting machine 11, a grouting port 12, a sedimentation separator 13, a conduit 14, a grouting port 15 and a vacuum pump 16; wherein,

[0036] The grouting machine 11 is connected with the grouting port 12 at one end of the pipeline 17, and is used to inject the slurry into the pipeline 17 from the grouting port 12, and provide the forward power for the slurry to push the slurry. The body advances in the pipeline 17; wherein, the grouting port 12 is parallel to the axis of the pipeline 17 to convert the pressure of the grouting machine 11 into power. Wherein, the slurry is cement slurry, the amount of water reducing agent added to the slurry is 1.2%, and the water-cement ratio is 1:2.

[0037] One end of the sedimentation separator 13 is connected to the slurry outlet 15 at the upper end of the other end of the pipeline 17 through a...

Embodiment 2

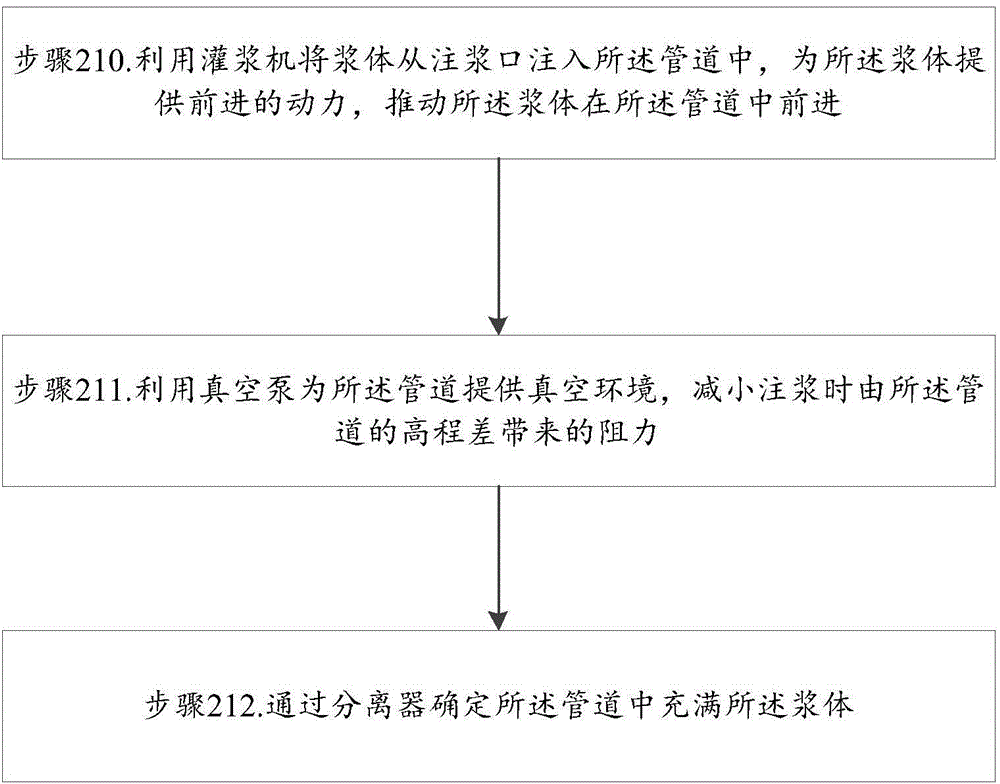

[0056] Corresponding to Embodiment 1, this embodiment provides a grouting filling method for abandoned oil and gas pipelines, such as figure 2 As shown, the method mainly includes the following steps:

[0057] Step 210, using a grouting machine to inject the slurry into the pipeline from the grouting port, and push the slurry forward in the pipeline;

[0058] In this step, the grouting machine is connected to the grouting port at one end of the pipeline, and the grouting machine is used to inject the prepared cement slurry into the pipeline, and provide forward power for the slurry to push the slurry in the Advance in the pipeline; close the second valve after a period of time to keep the pipeline airtight. Wherein, the grouting port is parallel to the axis of the pipeline, so as to convert the pressure of the grouting machine into power.

[0059] The switch state of the grouting port is controlled by the first valve.

[0060] Wherein, the position setting of the grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com