Construction method for undercrossing of urban shallow tunnel through soft-flow plastic red clay layer

A technology for shallow buried tunnels and construction methods, which is applied in tunnels, tunnel linings, and earthwork drilling and mining, etc., can solve the problems of road safety, quality, and progress of urban pipeline network in construction safety, and achieve strong construction operability and operation. Simple, low grouting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

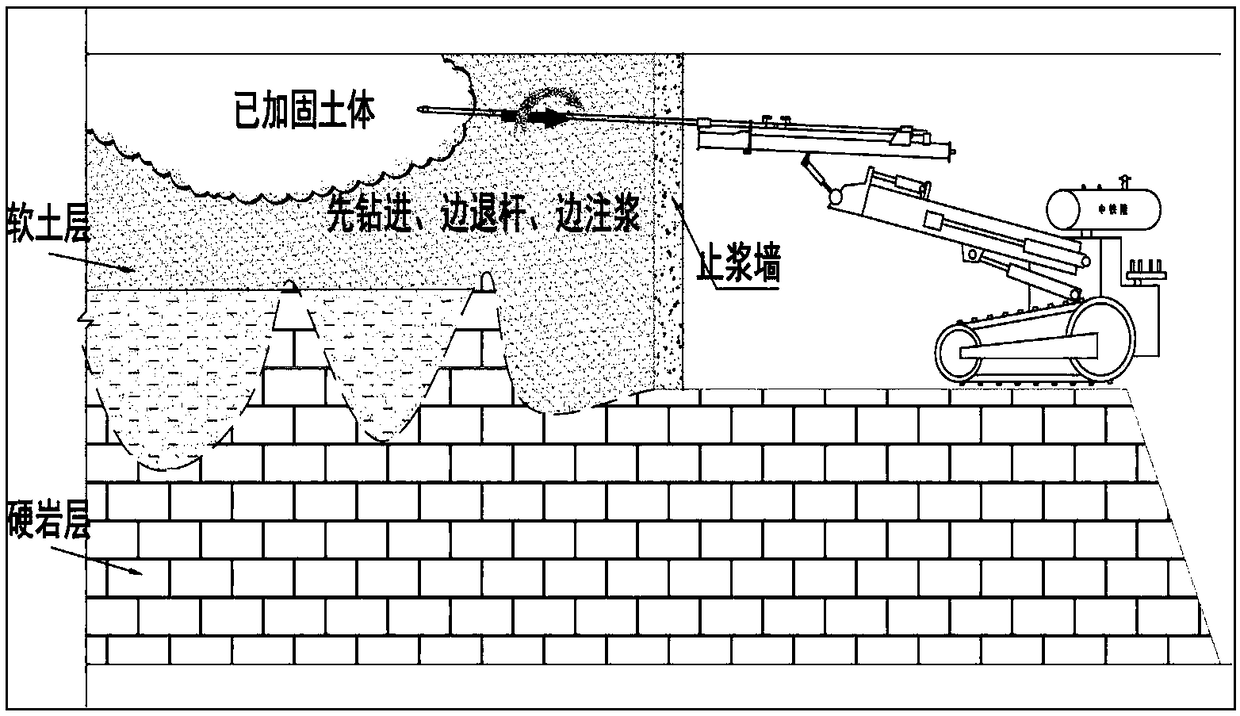

[0044] like figure 1 As shown, the invention provides a kind of construction method of soft flow plastic red clay layer under a kind of urban shallow buried tunnel, and concrete steps are successively:

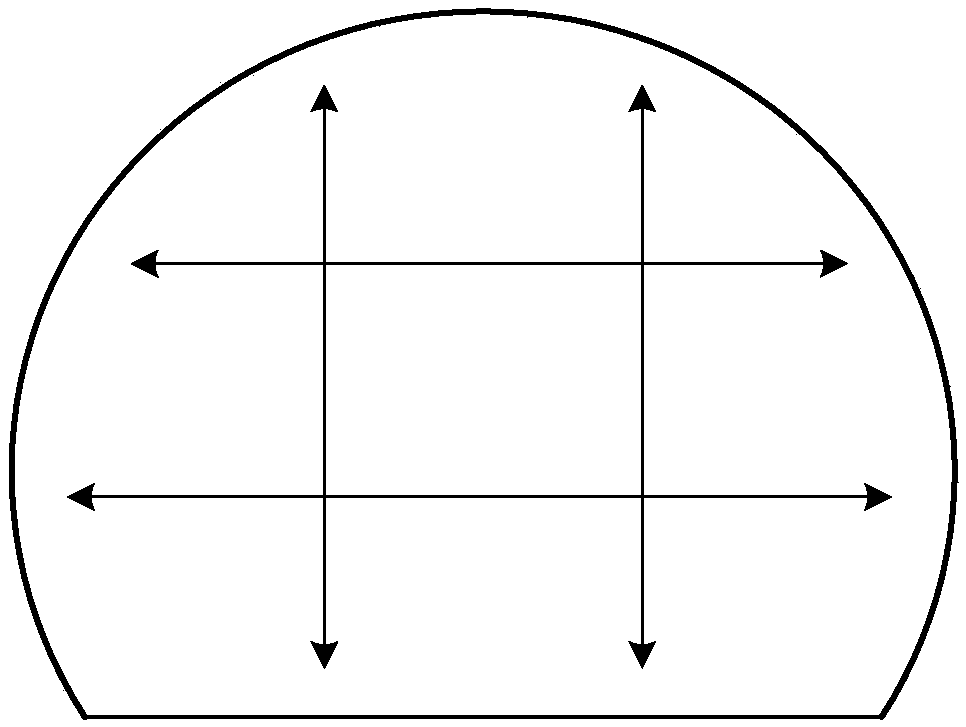

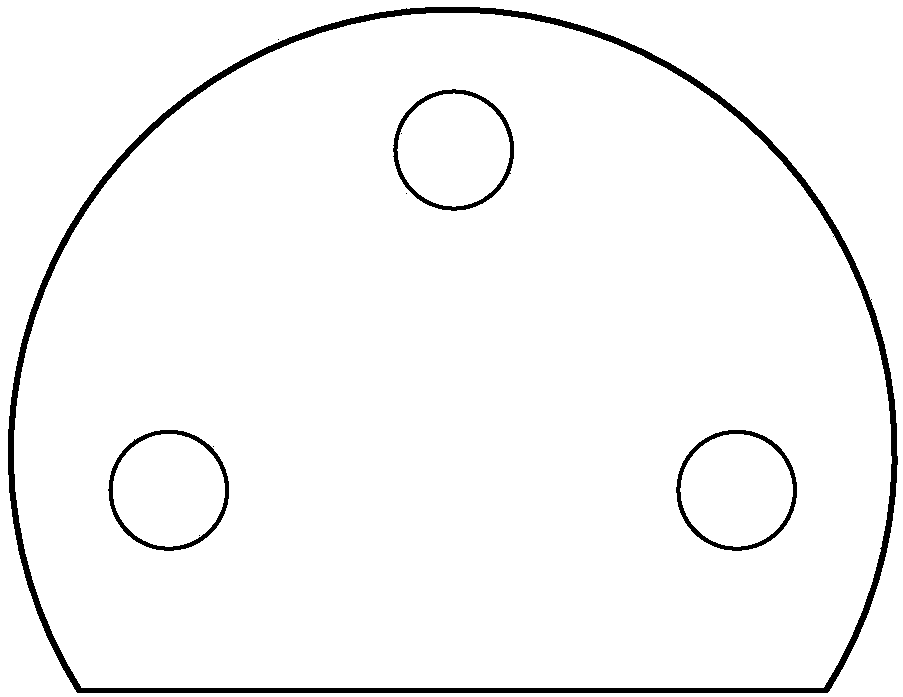

[0045] Step 1. Use geological radar scanning, advanced horizontal drilling and infrared water detection to detect the distribution of red clay in front of the tunnel and the water outlet, and adjust the grouting parameters according to the detection results to avoid blind grouting. For example, figure 2 and image 3 shown;

[0046] Step 2, build a simple grout-stop wall: for the convenience of construction, the reinforcement mesh is used to spray 500mm thick C25 concrete for the construction of the grout-stop wall, and at the same time, the anchor bars are implemented in the ring direction of the initial branch of the tunnel face, and are connected with the steel mesh as a whole , to increase its stress characteristics. The steel mesh adopts φ8@150×150 single-layer mesh, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com