A method for preparing a multi-stage pre-embedded prefabricated component of a steel grouting sleeve connection joint

A technology for grouting sleeves and connecting joints, which is applied to building components, structural elements, building reinforcements, etc., can solve the problems of troublesome processing and installation, high cost, and the connection method of steel bars cannot meet the area percentage of lap joints of tension steel bars. , to achieve the effect of simple manufacturing process, low cost, improved seismic performance and anti-continuous collapse performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] A method for preparing a multi-stage pre-embedded prefabricated component of a steel bar grouting sleeve connection joint, comprising the following steps:

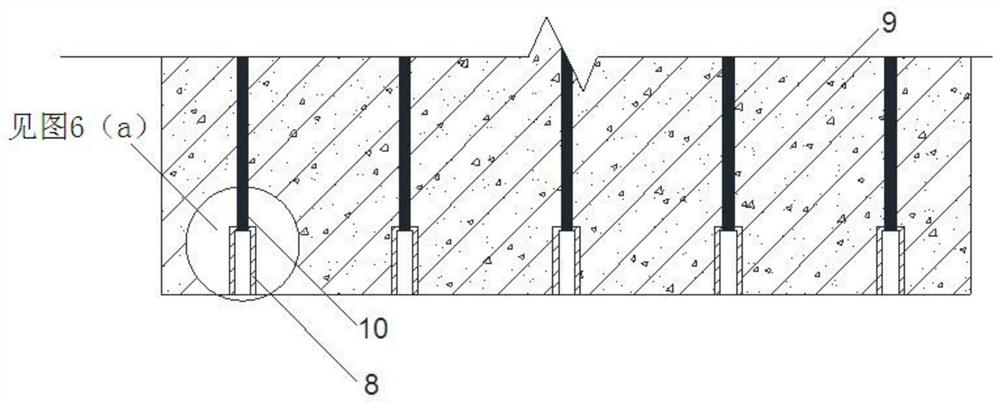

[0039] (1) table formwork is prepared, reinforcing bar 10 is set in table formwork;

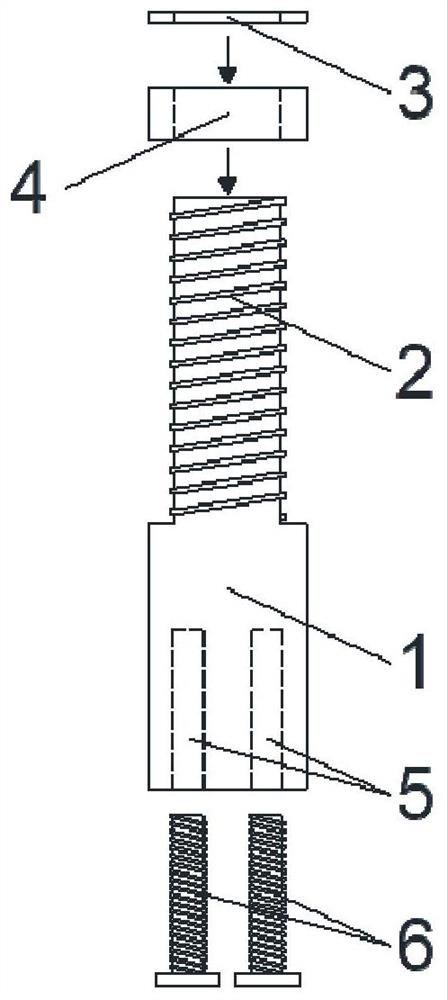

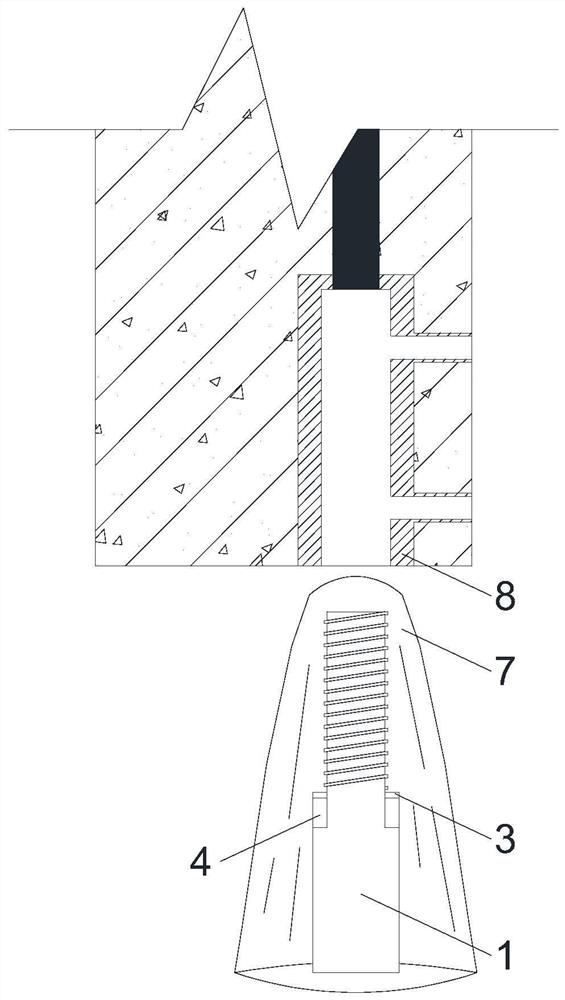

[0040] (2) Connect the grouting sleeve 8 at the bottom of the steel bar, set a magnetic guide sleeve at the bottom of part of the grouting sleeve 8 so that the positions of the grouting sleeve 8 are not at the same height, and stagger the pre-embedded grouting sleeve 8; the magnetic guide sleeve includes a guide sleeve Body, the guide cylinder body is divided into the guide cylinder lower part 1 and the guide cylinder upper connecting section 2, the outer diameter of the guide cylinder upper connecting section 2 is smaller than the outer diameter of the guide cylinder lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com