Compacting grouting method

A technology of compaction grouting and grouting, which is applied in the field of compaction grouting, can solve problems such as uneven stress on subways, low operating efficiency, uneven subway tracks, etc., to improve grouting efficiency, ensure safety, and structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

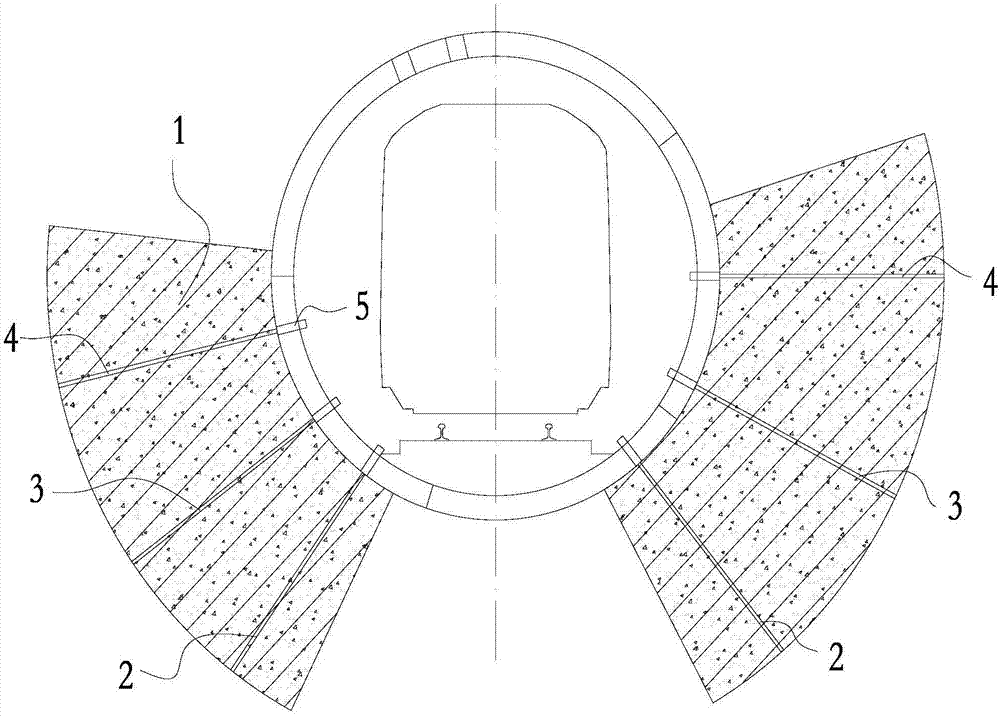

[0036] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0037] like figure 1 As shown, the compaction grouting method in the present embodiment comprises the following steps:

[0038] 1) Drill grouting holes on the standard block of the ring segment 1, the grouting holes include the first group of grouting holes 2, the second group of grouting holes 3 and the third group of grouting holes distributed sequentially from bottom to top 4. Taking the plane passing through the center axis of the tunnel and the center line of the rail as the reference plane, the first group of grouting holes 2, the second group of grouting holes 3 and the third group of grouting holes 4 each include two reference planes It is called distributed grouting holes. It should be pointed out that during the process of drilling grouting holes, the distribution of steel bars under the ground needs to be surveyed, and the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com