Rapid pre-reinforcement grouting method for excavation of tunnel face of deeply-buried high-pressure water-rich tunnel

A technology for water-rich tunnels and face surfaces, which is used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of a large number of drilling holes for curtain grouting, poor grouting reinforcement effect, and high grouting construction strength. The effect of reducing the number of disasters, shortening the time-consuming work, and ensuring safe and smooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

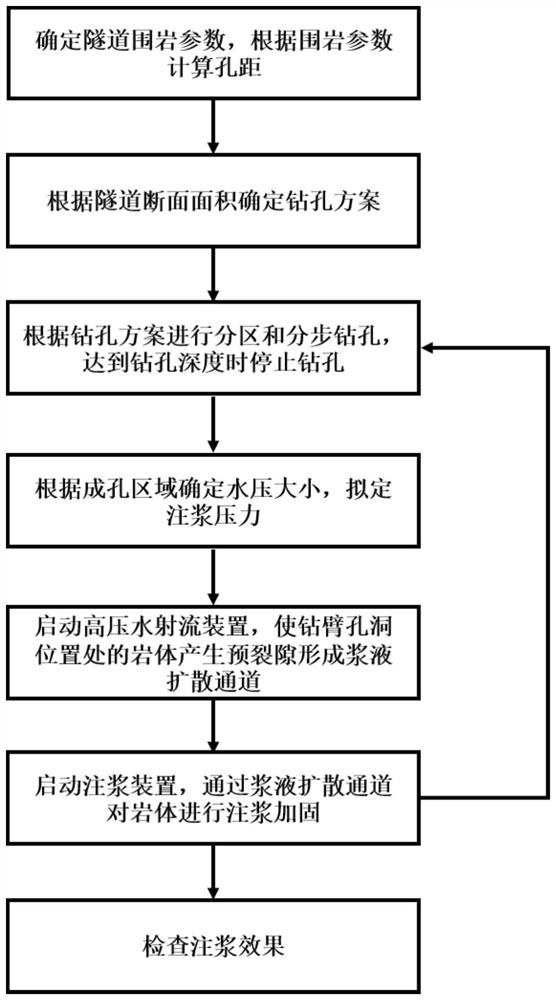

[0040] Such as figure 1 As shown, the rapid pre-reinforcement grouting plugging method for excavating the face of a deep-buried high-pressure water-rich tunnel includes the following steps:

[0041] S1. Determine the surrounding rock parameters of the tunnel, and calculate the hole distance according to the surrounding rock parameters.

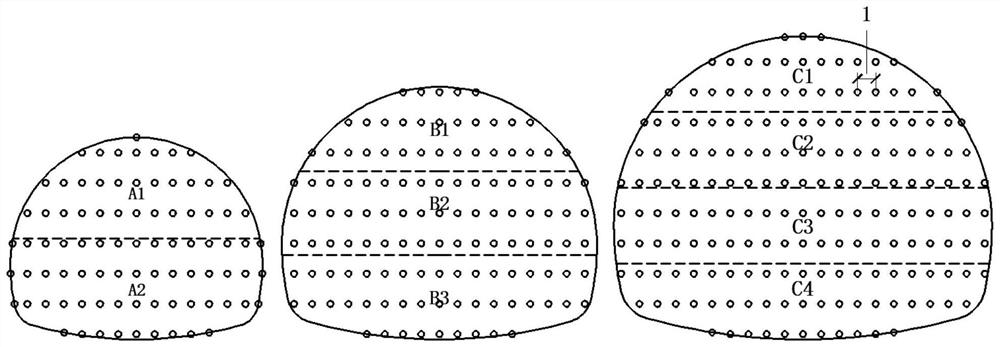

[0042] TSP advanced geophysical prospecting technology is used to determine the parameters of the surrounding rock of the tunnel, combined with grouting materials to obtain multiple physical and mechanical parameters, including: rock mass permeability coefficient, rock mass Poisson's ratio, rock mass elastic modulus, viscosity ratio, and porosity. The hole distance is calculated according to the surrounding rock and grouting material parameters, as follows:

[0043] (1) Calculation of hole distance

[0044] S11. According to the scope of grouting reinforcement, the calculation formula of the hole distance is as follows:

[0045]

[0046]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com