Construction method of interwall grouting waterproofing and strengthening shaft wall structure under the protection of frozen wall

A construction method and a technology for freezing walls, which are applied in earth-moving drilling, shaft equipment, shaft lining and other directions, can solve the problems of the service life of equipment in the shaft, occupying the shaft for a long time, affecting the safety of the mine, etc. Cost-effective and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

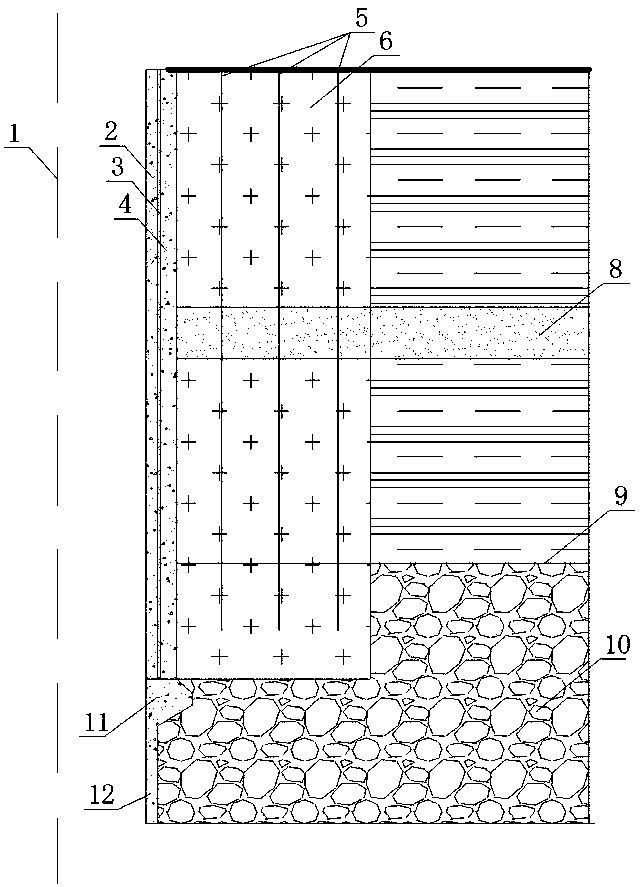

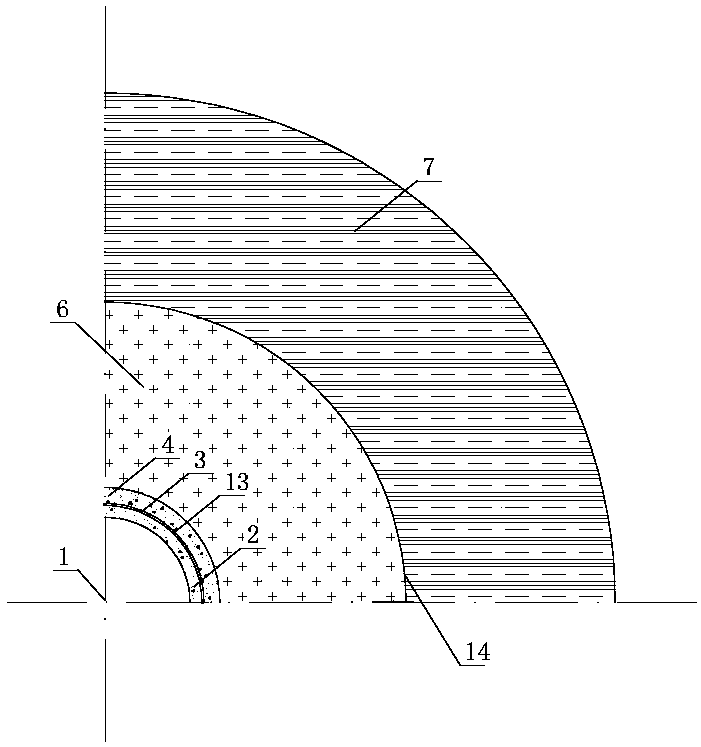

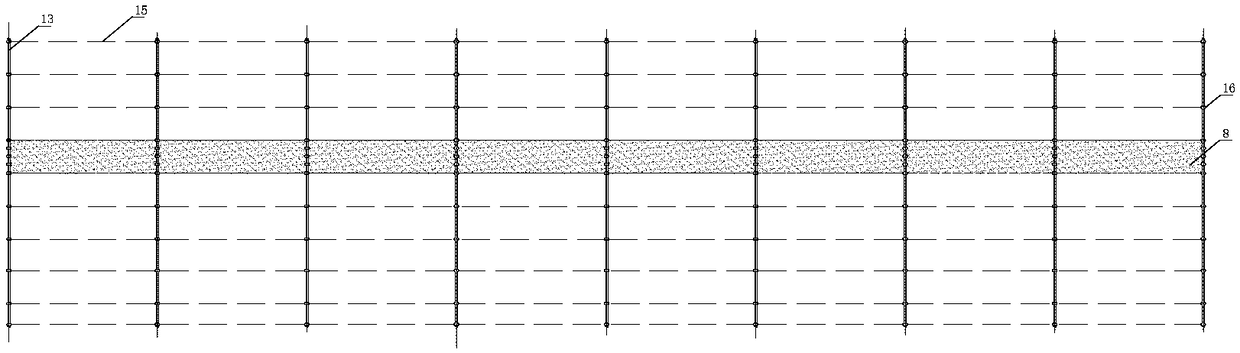

[0036] Embodiment 1: as figure 1 As shown, a technology and construction method for interwall grouting waterproofing and strengthening the shaft wall structure under the protection of the frozen wall. First, when the inner shaft wall 2 is constructed from bottom to top, according to the diameter of the shaft shaft, the inner shaft wall Evenly arrange 4 to 10 grouting pipes 13 between the outer well wall 4, and reserve the grouting ports 16 at the joints 15 of the outer well wall, and reserve the grouting ports when encountering the surface soil aquifer 16 (1-2m intervals).

[0037] Grouting process: the construction of the inner well wall 2 is completed, and the strength reaches more than 70% of the design strength, and before the frozen wall 6 is melted, the grouting between the inner and outer well walls is started; the grouting sequence is first down, then up, and then up From the bottom, the grout is first thick and then thin, and is injected symmetrically along the wellb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com