Shield tunnel reinforcement method

A technology of shield tunneling and grouting, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems that the shield tunnel reinforcement effect is not good enough, affects the smooth operation of the subway, and affects the integrity of the tunnel, etc., and achieves a good reinforcement effect , avoid the uplift of the tunnel strata, and improve the effect of operation guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

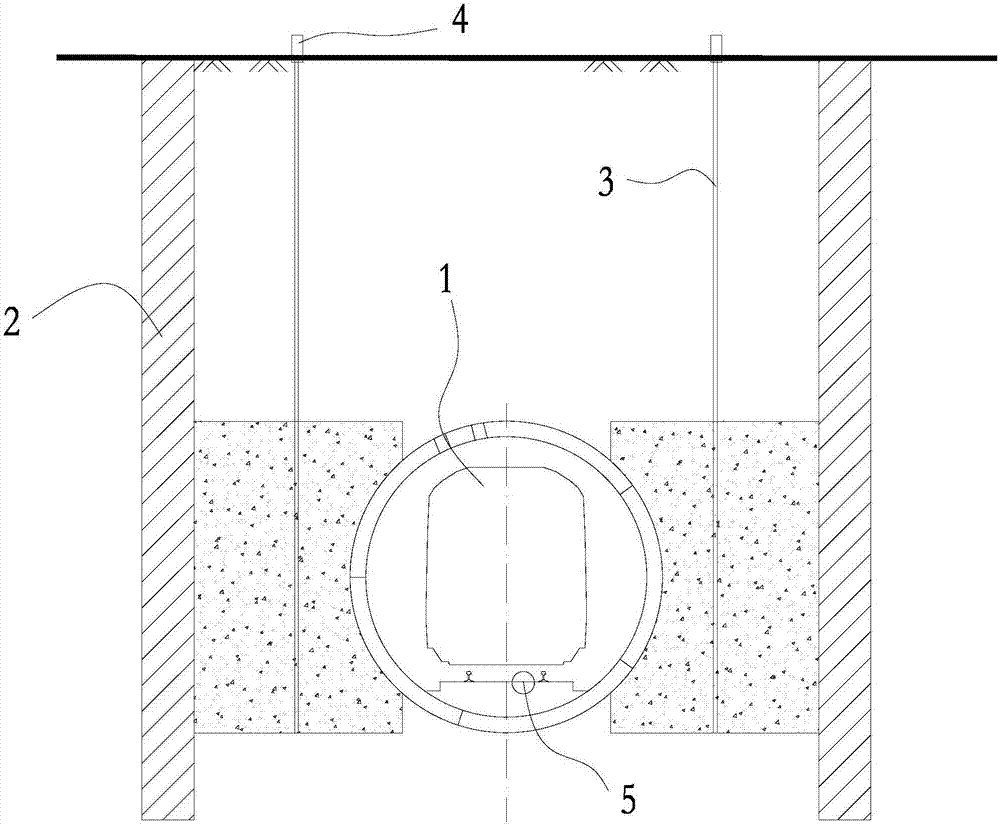

[0040] Such as figure 1 As shown, the shield tunnel reinforcement method in the present embodiment comprises the following steps:

[0041] 1) Stirring piles 2 are formed on the outside of shield tunnel 1, and the number of stirring piles 2 will decrease accordingly due to compaction and grouting thereafter;

[0042] 2) A grouting hole is set between the stirring pile 2 and the shield tunnel 1, a sleeve valve pipe 3 is installed in the grouting hole, and a one-way valve 4 is installed on the upper end of the sleeve valve pipe 3, and the one-way valve 4 makes During the grouting process, the grout will not flow back, so that the grout can enter the soil smoothly. It should be pointed out that in this embodiment, the one-way valve 4 is connected to the sleeve valve pipe 3 through a flange. The structure of the flange is simple and can make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com