Method and structure for reinforcing flat hole grouting roadbed without damaging road surface

A technology for strengthening structures and subgrades, which is applied in infrastructure engineering, roads, roads, etc., can solve the problems of destroying the structural integrity of the pavement, cracking of the pavement structure, and affecting the function and service life of the pavement, so as to ensure the overall integrity and reduce the The effect of grouting pressure, improving grouting efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

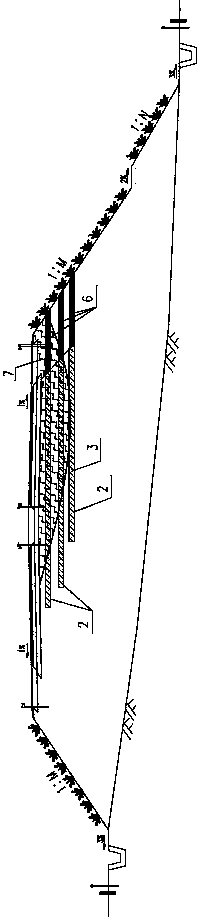

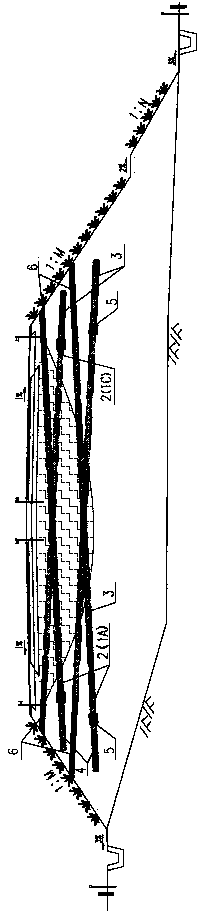

[0031] Combine below figure 1 , Figure 5 , the present invention is described in further detail:

[0032] A flat hole grouting roadbed reinforcement method without damaging the road surface, the steps are:

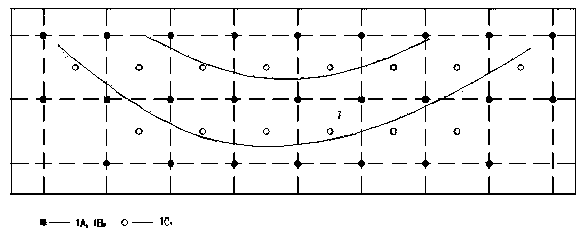

[0033] A. 7 or subgrade Determination of subgrade uneven settlement disease area instability disease area 8, subgrade slope grouting hole location. Draw a grout diffusion square network according to the width of the subgrade working face to be reinforced by grouting and the grout diffusion radius (such as figure 1 As shown), the intersection point of the square grid is taken as the initial plane position of the drilling position, and then the hole depth and inclination angle are determined according to the damage characteristics of the roadbed and the purpose of reinforcement (the uneven settlement area of the roadbed is generally 0°~3°, and the instability of the roadbed is controlled The area is generally 20°~45°), and the drilling hole position is adjusted to tr...

Embodiment 2

[0042] according to figure 2 , image 3 , Figure 4 , Figure 6 It can be seen that a flat-hole grouting subgrade reinforcement structure that does not damage the road surface consists of a grouting hole 1, a first-drilled grouting hole 1A, a grouting hole 1B that is drilled alternately, an auxiliary grouting hole 1C, and a grouting pattern. Pipe 2, cement slurry 3, seamless cement grouting outer pipe 4, joint thread 5, hole sealing material 6, roadbed uneven settlement disease area 7, roadbed instability disease area 8, characterized in that: in the grouting hole 1. Install the grouting flower tube 2 and the seamless grouting outer tube 4. The grouting flower tube 2 and the seamless grouting outer tube 4 are connected by joints and threads 5. In the uneven diseased area of the subgrade 7, holes are designed around the outside of the diseased area. Drill holes on the top position to form the grouting hole 1A first, then drill the grouting hole 1B by step-drilling alterna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com