Intelligent grouting hole device for tunnel lining trolley

A technology for lining trolleys and grouting holes, applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems of low lining quality, low lining construction efficiency, manual opening and closing of grouting holes, etc., to improve lining quality, The effect of reducing grouting construction accidents and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

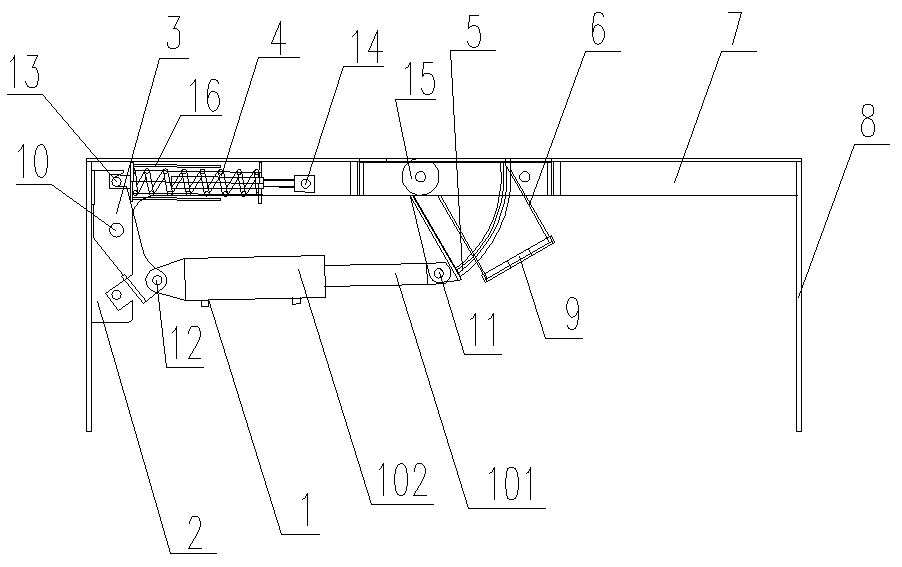

[0013] like Figure 1 to Figure 2 As shown, the intelligent grouting hole device for the tunnel lining trolley includes a horizontal beam 7 and a column 8 arranged at both ends of the beam 7 and vertically connected with the beam 7 .

[0014] A grouting pipe 6 is fixedly arranged on the beam 7, and the grouting pipe 6 is a channel for injecting concrete. The upper part of the grouting pipe 6 is open and the lower part is closed.

[0015] One of the two columns 2 is provided with a fixed lug 2 , and the fixed lug 2 is hinged with a movable lug 3 through a first pin shaft 10 .

[0016] A spring 4 and a hydraulic cylinder 1 are arranged between the movable ear plate 3 and the grouting pipe 6 .

[0017] A baffle 5 is provided between the hydraulic cylinder 1 and the grouting pipe 6 .

[0018] One end of the baffle plate 5 is hinged with the end of the piston rod 101 of the hydraulic cylinder 1 through the second pin 11, and the other end of the baffle plate 5 is passed through t...

Embodiment 2

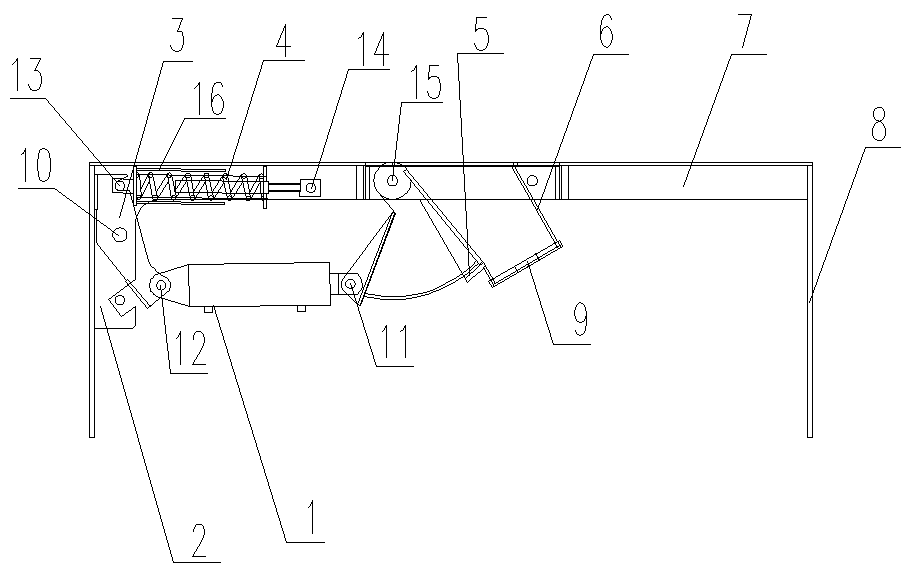

[0027] like Figure 1 to Figure 2 As shown, the intelligent grouting hole device for the tunnel lining trolley includes a horizontal beam 7 and a column 8 arranged at both ends of the beam 7 and vertically connected with the beam 7 .

[0028] A grouting pipe 6 is fixedly arranged on the beam 7, and the grouting pipe 6 is a channel for injecting concrete. The upper part of the grouting pipe 6 is open and the lower part is closed.

[0029] One of the two columns 2 is provided with a fixed lug 2 , and the fixed lug 2 is hinged with a movable lug 3 through a first pin shaft 10 .

[0030] A spring 4 and a hydraulic cylinder 1 are arranged between the movable ear plate 3 and the grouting pipe 6 .

[0031] A baffle 5 is provided between the hydraulic cylinder 1 and the grouting pipe 6 .

[0032] One end of the baffle plate 5 is hinged with the end of the piston rod 101 of the hydraulic cylinder 1 through the second pin 11, and the other end of the baffle plate 5 is passed through t...

Embodiment 3

[0042] like Figure 1 to Figure 2 As shown, the intelligent grouting hole device for the tunnel lining trolley includes a horizontal beam 7 and a column 8 arranged at both ends of the beam 7 and vertically connected with the beam 7 .

[0043] A grouting pipe 6 is fixedly arranged on the beam 7, and the grouting pipe 6 is a channel for injecting concrete. The upper part of the grouting pipe 6 is open and the lower part is closed.

[0044] One of the two columns 2 is provided with a fixed lug 2 , and the fixed lug 2 is hinged with a movable lug 3 through a first pin shaft 10 .

[0045] A spring 4 and a hydraulic cylinder 1 are arranged between the movable ear plate 3 and the grouting pipe 6 .

[0046] A baffle 5 is provided between the hydraulic cylinder 1 and the grouting pipe 6 .

[0047] One end of the baffle plate 5 is hinged with the end of the piston rod 101 of the hydraulic cylinder 1 through the second pin 11, and the other end of the baffle plate 5 is passed through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com