Graphene and nonferrous metal tailings-based foamed light wallboard and preparation method thereof

A non-ferrous metal, lightweight wallboard technology, applied in clay products, ceramic products, other household appliances, etc., can solve the problems of environmental safety and human health hazards, multi-manpower, financial and material resources, and management difficulties. Achieve the effect of improving oxidation resistance, avoiding matrix cracking and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A foamed lightweight wallboard based on graphene and non-ferrous metal tailings, including main materials and auxiliary materials. In parts by weight, the main materials include 82 parts of non-ferrous metal tailings; auxiliary materials include 2 parts of graphene and 8 parts of vermiculite , 15 parts of chopped carbon fiber, 7 parts of aluminum fluoride, 6 parts of aluminum silicate fiber, 10 parts of montmorillonite, 10 parts of zirconium silicate, 5 parts of clay, 2 parts of sodium tripolyphosphate, 10 parts of cosolvent, foam 2 parts of agent and 2 parts of stabilizer.

[0040] The non-ferrous metal tailings refer to magnesium ore tailings, aluminum ore tailings and tungsten ore tailings.

[0041] The clay is high liquid limit earth and diatomaceous earth.

[0042] The fluxing agent is cryolite and bosmanite.

[0043] Described whipping agent is tapioca starch and carbon powder.

[0044] The stabilizer is manganese dioxide.

[0045] The length of the chopped ca...

Embodiment 2

[0059] A foamed lightweight wallboard based on graphene and non-ferrous metal tailings, including main materials and auxiliary materials. In parts by weight, the main materials include 80 parts of non-ferrous metal tailings; auxiliary materials include 1 part of graphene and 10 parts of vermiculite , 13 parts of chopped carbon fiber, 4 parts of aluminum fluoride, 4 parts of aluminum silicate fiber, 7 parts of montmorillonite, 5 parts of zirconium silicate, 4 parts of clay, 2 parts of sodium tripolyphosphate, 15 parts of cosolvent, foam 2 parts of agent and 2 parts of stabilizer.

[0060] The non-ferrous metal tailings refer to gold ore tailings, nickel ore tailings and cobalt ore tailings.

[0061] The clay is white clay and bentonite.

[0062] The flux is boron mud and light-burned magnesia.

[0063] Described whipping agent is tapioca starch and calcium carbonate.

[0064] The stabilizer is cobalt oxide.

[0065] The treatment of non-ferrous metal tailings and the prepar...

Embodiment 3

[0068] A foamed lightweight wallboard based on graphene and non-ferrous metal tailings, including main materials and auxiliary materials. According to parts by weight, the main materials include 85 parts of non-ferrous metal tailings; auxiliary materials include 7 parts of graphene and 13 parts of vermiculite , 18 parts of chopped carbon fiber, 8 parts of aluminum fluoride, 7 parts of aluminum silicate fiber, 13 parts of montmorillonite, 17 parts of zirconium silicate, 8 parts of clay, 4 parts of sodium tripolyphosphate, 7 parts of cosolvent, foam 4 parts of agent, 3 parts of stabilizer.

[0069] The non-ferrous metal tailings refer to magnesium ore tailings, aluminum ore tailings and tin ore tailings.

[0070] The clay is a high liquid limit soil.

[0071] The fluxes are talc, diopside and illite.

[0072] The foaming agent is tapioca starch.

[0073] The stabilizers are manganese dioxide and cobalt oxide.

[0074] The treatment of non-ferrous metal tailings and the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

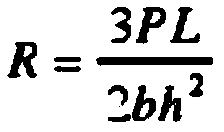

| length | aaaaa | aaaaa |

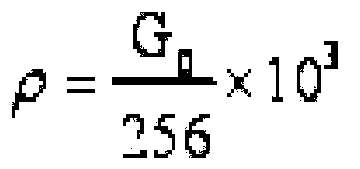

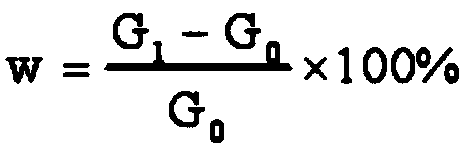

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com