Novel dry powder emulsion paint

A dry powder latex, a new type of technology, applied in the field of coatings, can solve problems such as labor-intensive, waste of resources, fading, etc., and achieve the effect of simple and fast construction process, convenient storage and transportation, and white and delicate surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

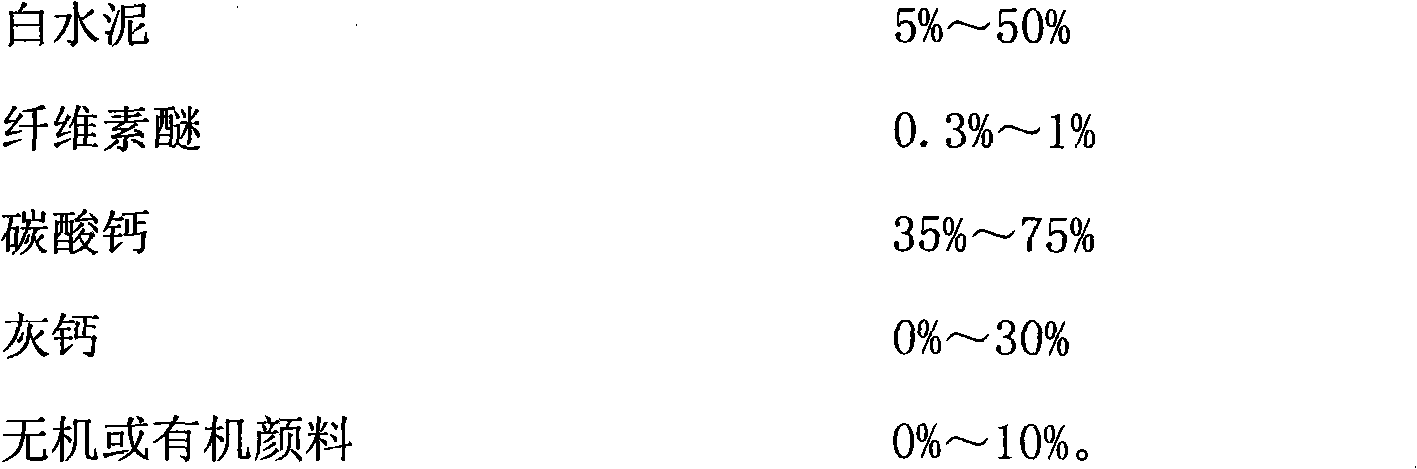

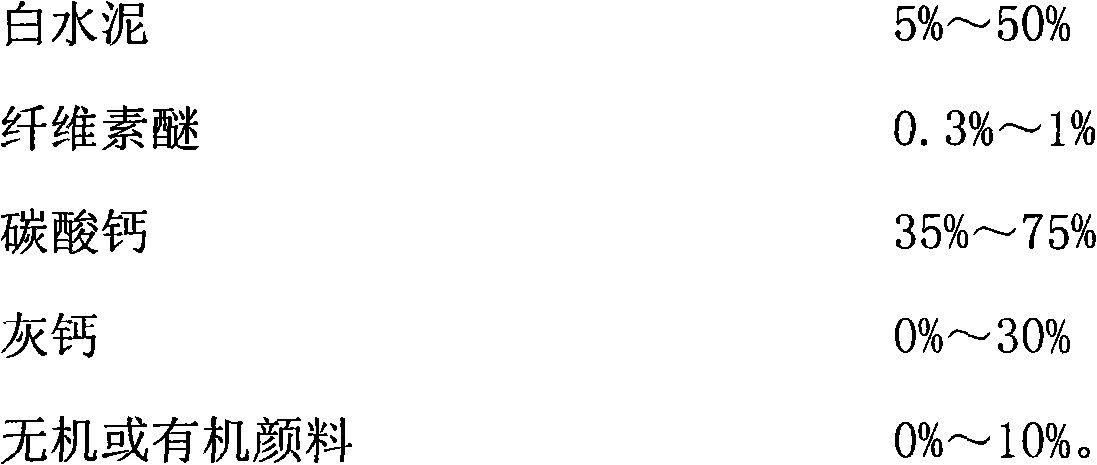

Method used

Image

Examples

Embodiment 1

[0024] The content of each component of the environment-friendly dry powder latex paint of the present embodiment is 21.6% of white cement, 0.4% of cellulose ether, 73% of calcium carbonate, and 5% of gray calcium. The above-mentioned components are dropped into the mixer by weight percentage, and after mixing, Packaging can make the finished product environment-friendly dry powder latex paint. During construction, add water to the environment-friendly dry powder latex paint, the ratio is dry powder latex paint: water = 10: 3.3, and it can be scraped and used after stirring evenly. The white dry powder latex paint of the present embodiment can be used for the decoration of building interior wall.

Embodiment 2

[0026] The content of each component of the environment-friendly dry powder latex paint of the present embodiment is 37% of white cement, 0.6% of cellulose ether, 45.4% of calcium carbonate, 15% of gray calcium, and 2% of inorganic or organic pigments. Put it into a mixer, mix evenly, and pack to make the finished product environment-friendly dry powder latex paint. During construction, add water to the environment-friendly dry powder latex paint, the ratio is dry powder latex paint: water = 10:7, and it can be sprayed after stirring evenly. The colored dry powder emulsion paint of the present embodiment can be used for the decoration of building inner wall.

Embodiment 3

[0028] The content of each component of the environment-friendly dry powder latex paint of the present embodiment is 42.2% of white cement, 0.8% of cellulose ether, 55% of calcium carbonate, and 2% of ash calcium. , Packaging can be made into a finished product environment-friendly dry powder latex paint. During construction, add water to the environment-friendly dry powder latex paint, mix well and then spray it. Dry powder latex paint: water = 10: 6.5. The white dry powder latex paint of the present embodiment can be used for building exterior wall spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com