Underground comprehensive pipe gallery structure deeply buried in soft soil and construction method of underground comprehensive pipe gallery structure

A technology of integrated pipe gallery and pipe gallery, which is applied in the direction of underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of difficult construction, high cost, and inability to implement, so as to reduce support costs, be economical and reasonable, Simple and fast construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

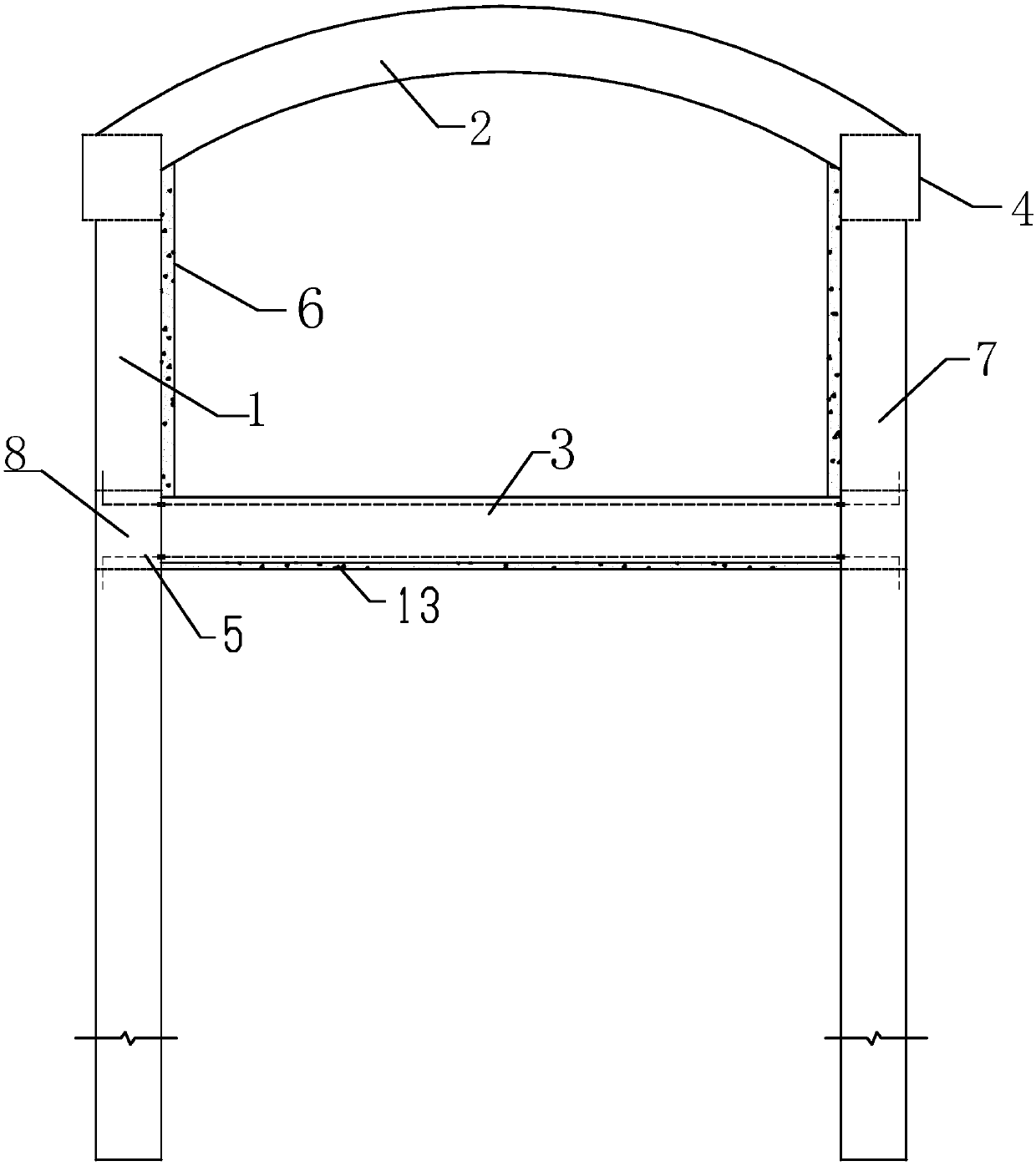

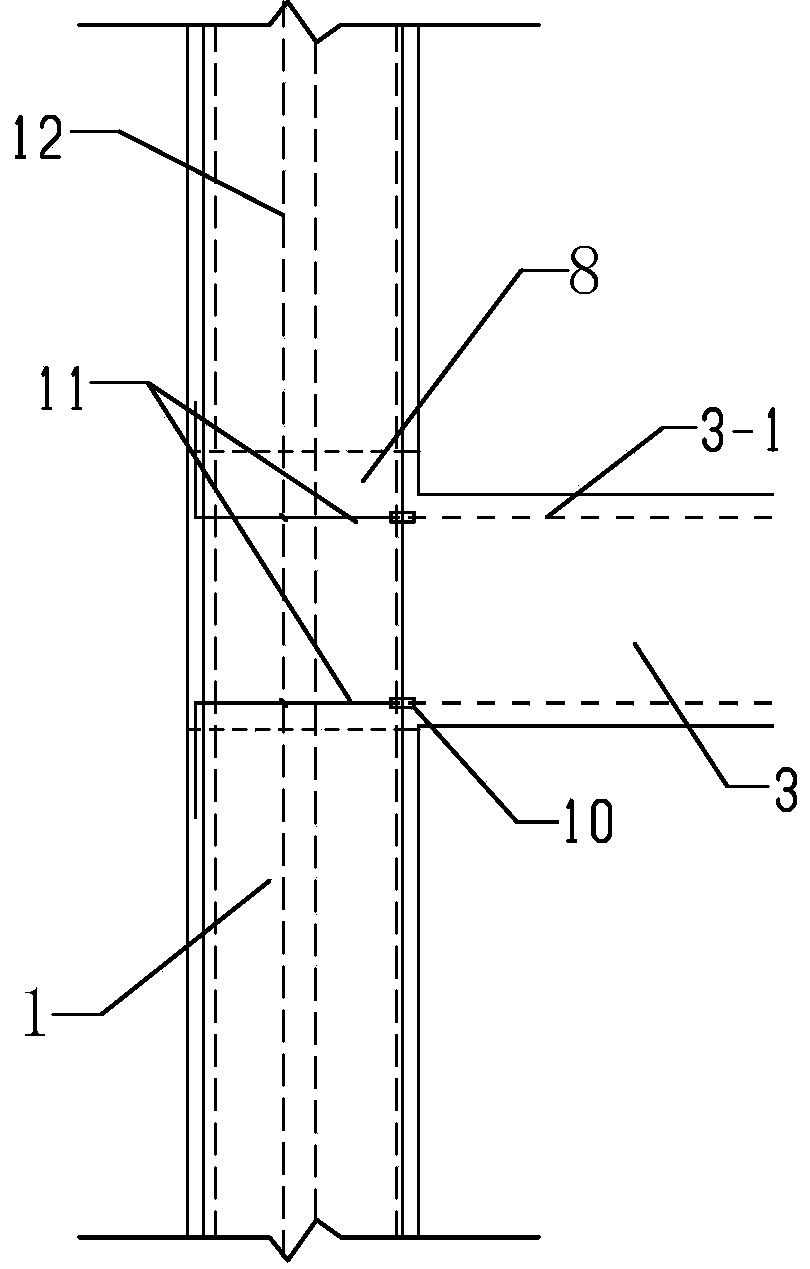

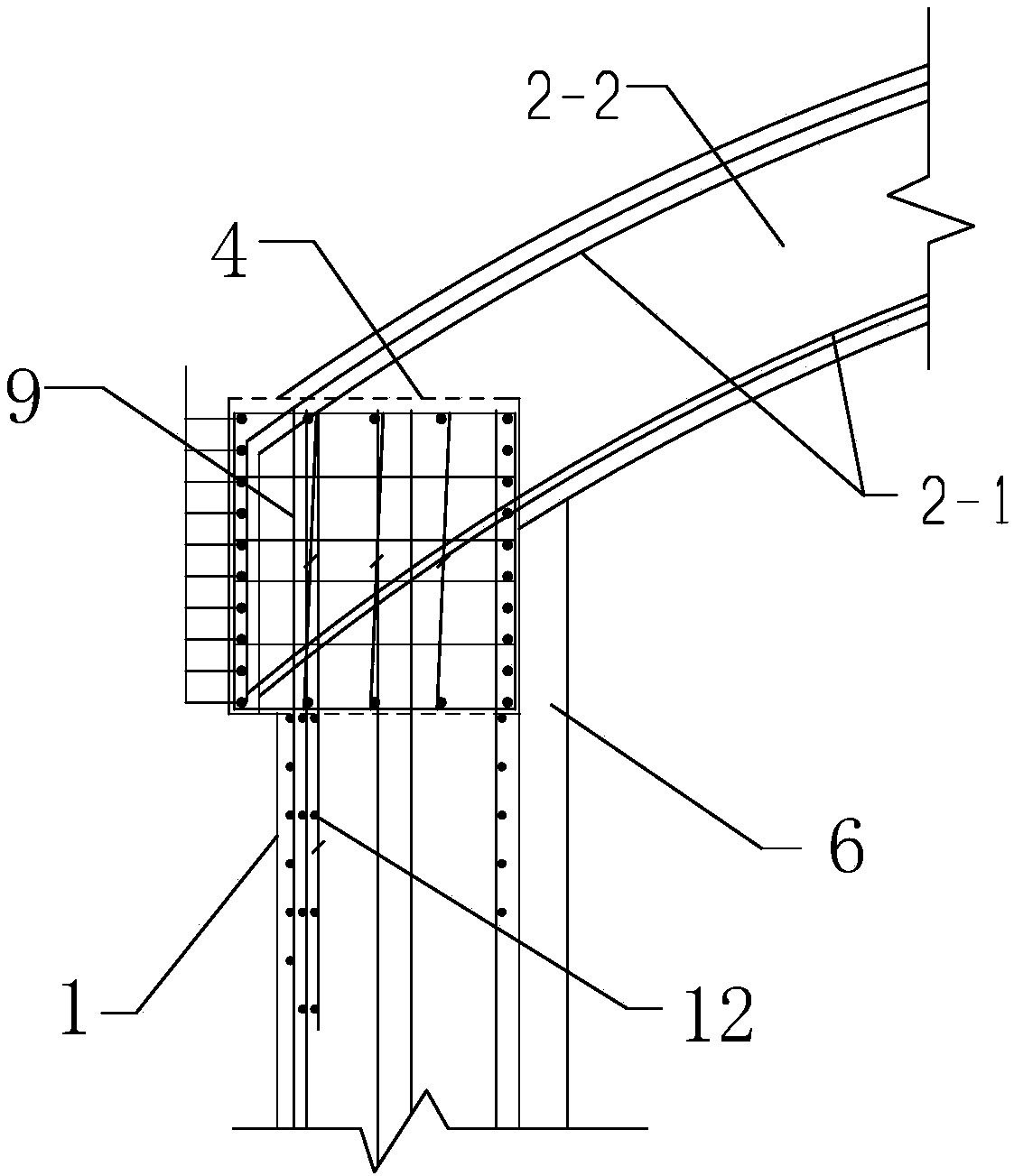

[0026] The present invention will be further described according to the above drawings. Such as figure 1 The pipe gallery structure shown is surrounded by left and right underground diaphragm walls 1 and 7 buried in deep soft soil below 10m, pipe gallery floor 3 and pipe gallery roof 2. The left and right underground diaphragm walls 1 , 7. The wall thickness is 800-1000mm, and the length is not less than 25m. Hidden beams 8 are buried at the joints between the left and right underground diaphragm walls 1, 7 and the pipe gallery bottom plate 3, and the hidden beams 8 are connected to the pipe gallery bottom plate 3 through steel bar connectors 5, as figure 2 As shown, the steel bar connector 5 is composed of an L-shaped connecting main bar 11 and a straight threaded connector 10, and the L-shaped connecting main bar 11 of each steel bar connector 5 is fixed on the steel cage 12 of the underground diaphragm wall, and Connect with one end of the straight threaded connector 10,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com