Construction technology of short sleeper vibration attenuation fastener with improved structure replacing elasticity short sleeper

A technology of vibration-damping fasteners and construction technology, which is applied in the track field, can solve problems such as gap expansion, vibration reduction reduction, and large gauge changes, so as to improve service life and maintainability, low maintenance and construction costs, and easy flow The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

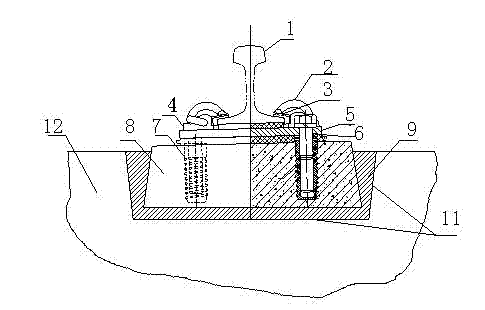

[0045] A construction process for replacing elastic short sleepers with short sleeper vibration-damping fasteners of improved structure, the specific steps of the construction process are as follows:

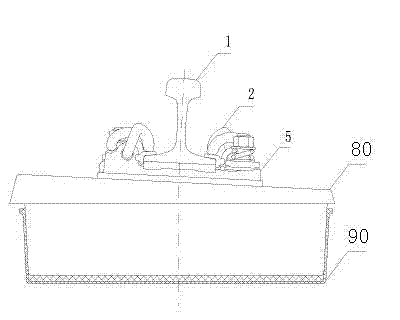

[0046] Step 1: Test and record the track position and geometric parameters of the section that needs to be rectified and replaced. Combined with the characteristics of railway construction, that is, railway construction is generally carried out at night, and the construction time is relatively short; The section is 24:00~5:00; the sections that need to be rectified and replaced shall be constructed in stages; according to the time available for construction, the sections that need to be rectified and replaced in each phase shall be determined. During each phase of construction, two steel rails 1 The old short sleeper 80 on the top and the fastener 5 on the old short sleeper 80 carry out the mode of rail-by-rail construction;

[0047] The second step: each phase of construction a...

specific Embodiment 2

[0097] The construction technology of this embodiment is basically the same as embodiment 1, combining Figure 3a , to group the old short sleepers on the same rail within the scope of each stage of construction, and each group is six; for each construction, one of the old short sleepers and fastener 5 in each group of six old short sleepers shall be Replacement; every working day construction adopts the construction technology of "pulling out one every five times". After six constructions, all the old short sleepers in the area that needs to be rectified and replaced in the first phase will be replaced;

Embodiment 3

[0099] The construction technique of this embodiment is with embodiment 1, as Figure 11As shown, in this embodiment, the suspended rail damping buckle disclosed by the patent No. 201120439915.4 is adopted, and a group of non-metallic elastic bodies 25 are arranged symmetrically on both sides of the rail 1 in the described chute-mounted suspension rail damping buckle. The radian of the arc surface of the end face coincides with the radian of the side of the rail, and the other end face is connected to the lateral support 26; the two lateral supports symmetrically arranged on both sides of the rail jointly form an inverted V-shaped support structure; the lateral support The bottom of 26 is located on the fastener base plate 28; the position combined with the side bracket 26 on the fastener base plate 28 has a structure to limit the side bracket, and the side bracket is carried out on the described fastener base plate. The position-limiting structure is used to limit the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com