Waste tire thin-wall hollow pile for treating soft foundation and construction method thereof

A technology based on waste tires and soft foundations, which is applied in foundation structure engineering, sheet pile walls, soil protection, etc., can solve the problems of long construction period of concrete hollow piles, low engineering applicability, and not very outstanding effects, etc., and achieves good results Long-term stability, simple and convenient construction process, and favorable effects for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

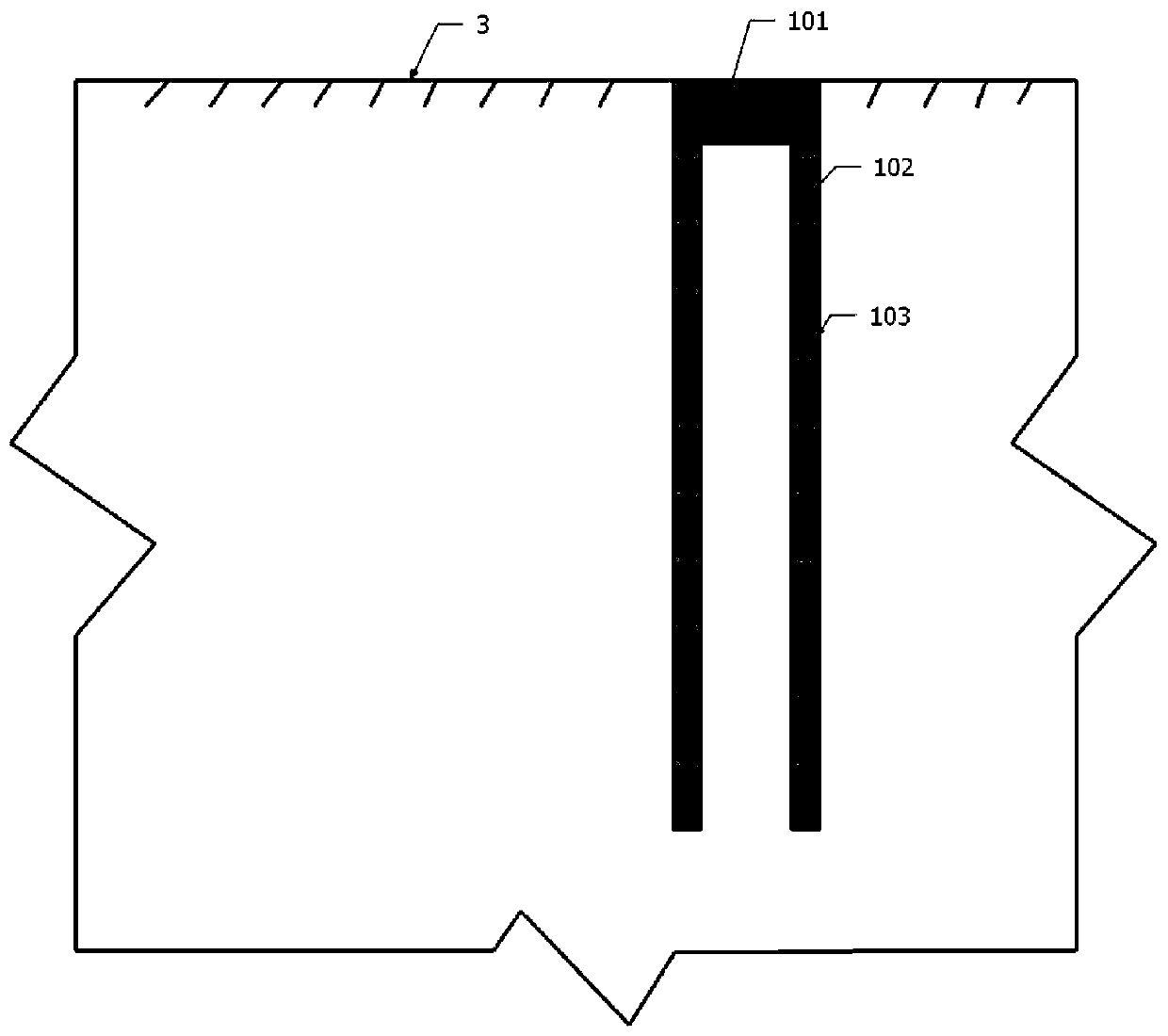

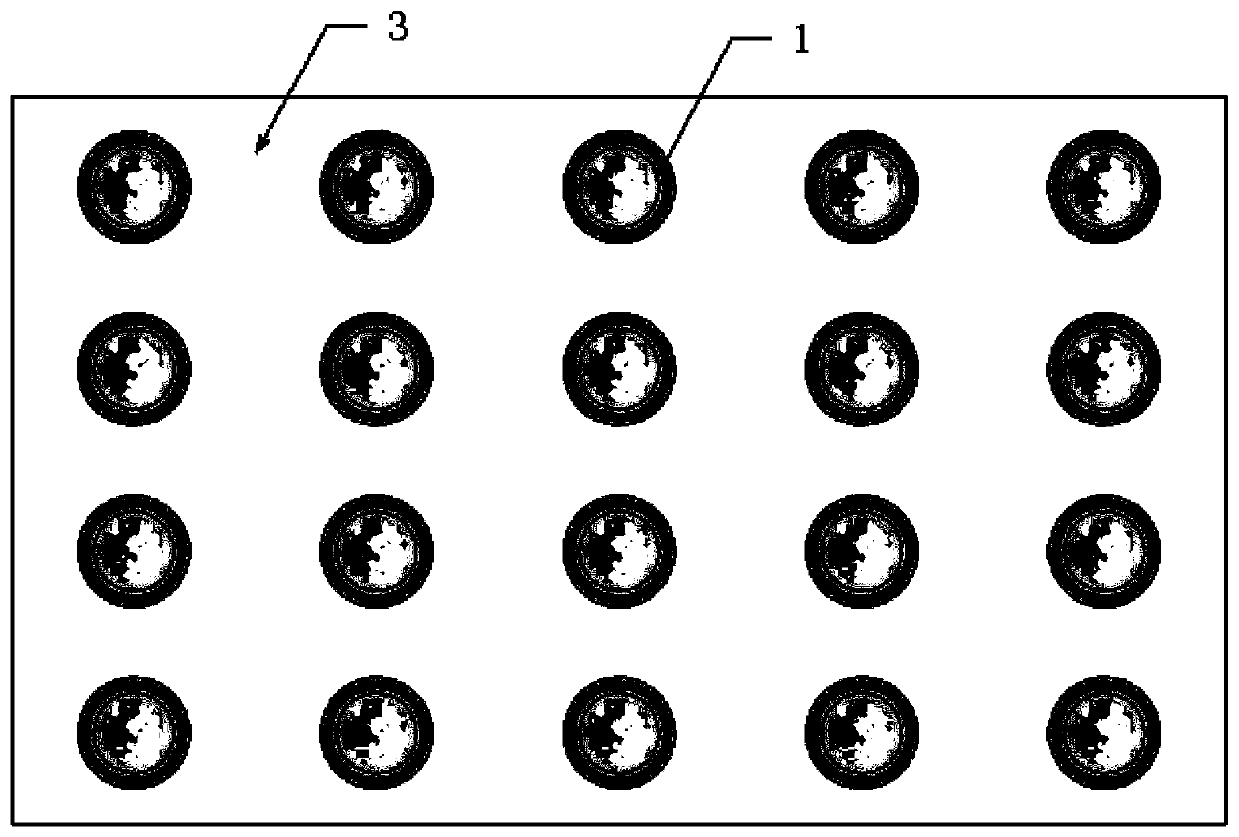

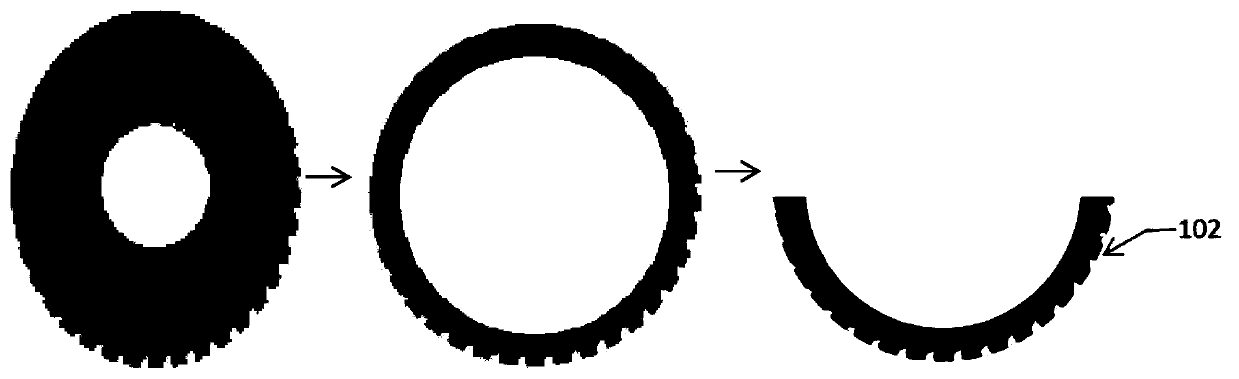

Embodiment 1

[0034] Such as figure 1 , press the tire cover mold 2 into the soft foundation 3 through a static pile driver, and insert the waste tire crowns 102 into the tire cover mold 2 one by one through the piston 4 with a scale; then, around the waste tire crown 102 Fill the cement slurry 103, and then pull out the tire cover mold 2 through the lifting hole 205; finally, take out the pile core soil below the ground surface, and refill the concrete as the hollow pile top cover 6, thereby forming a hollow pile with a length of 3-10m and a thickness of 3-5cm thin-walled hollow pile 1. The hollow pile 1 has a length of 3-10m and an inner diameter of 50cm. Soft foundation 3 is a loose or medium-dense sandy foundation with a relative density of less than 55%, or a soft clay foundation between plastic and fluid plastic. The poured cement slurry 103 has a strength of M10 or above, forming a thin-walled hollow pile 1 with the waste tire crown 102 as the core and the cement slurry 103 as the ...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is that the inner diameter of hollow pile 1 is 70cm, and the model of tire cover mold 2 is 63cm*70cm*3.3cm*0.2cm (inner shell diameter*outer shell diameter*cavity thickness*inner shell thickness) , the rest of the structure and construction methods are the same.

Embodiment 3

[0041] The difference between this embodiment and Embodiment 1 is that the inner diameter of hollow pile 1 is 110cm, and the model of tire cover mold 2 is 103cm*110cm*3.2cm*0.3cm (inner shell diameter*outer shell diameter*cavity thickness*inner shell thickness) , the rest of the structure and construction methods are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com