Multi-joint self-expansion anchor rod

A bolt and self-expanding technology, which is used in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of failure to fully exert the mechanical function of the bolt body, the impact of tunnel engineering quality and progress, the strength of the rod body material and the section Require advanced issues, achieve high social and economic value, good support effect, simple and fast construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the actual application form of the present invention is not limited to the illustrated embodiment.

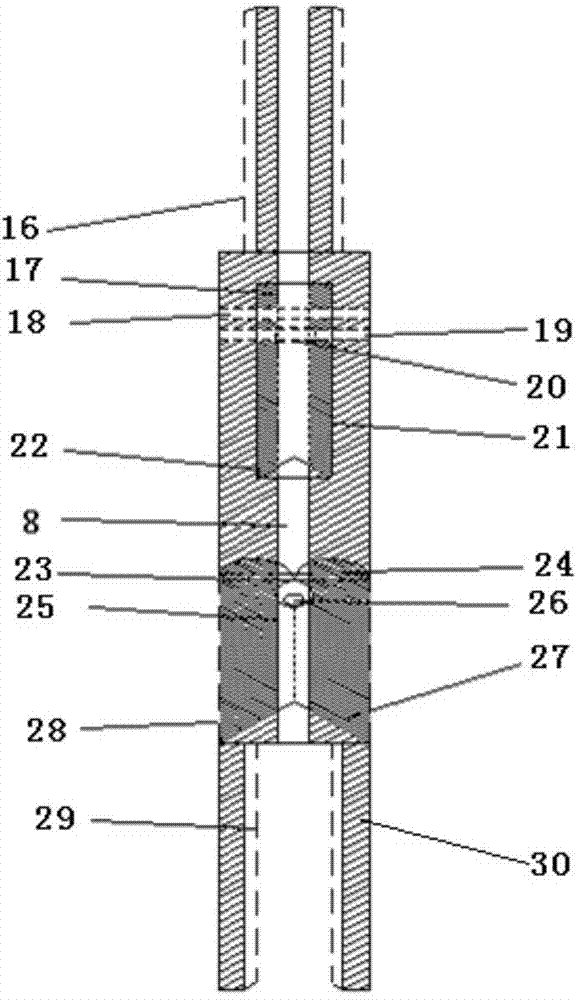

[0020] Referring to the accompanying drawings, the multi-section head self-expanding anchor rod of the present invention includes a long rod-shaped anchor head 1 and one or more segments of the anchor rod body 30 matched with the anchor head 1 .

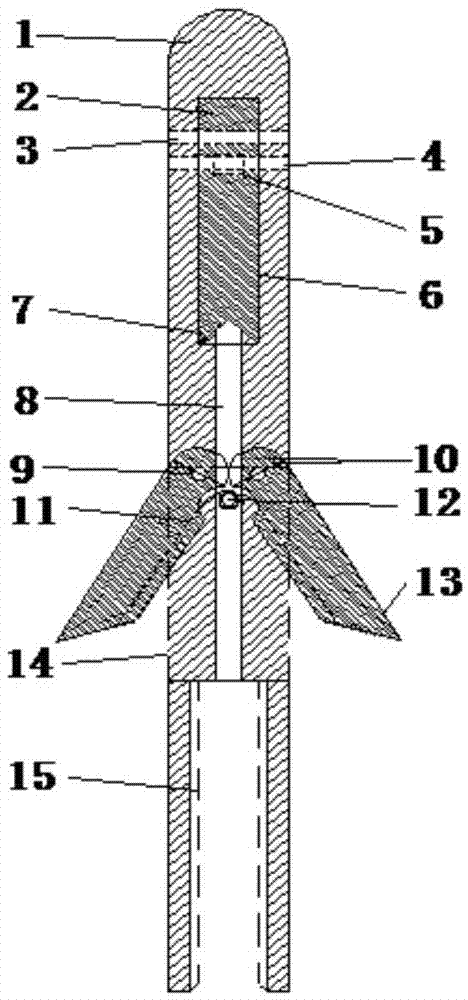

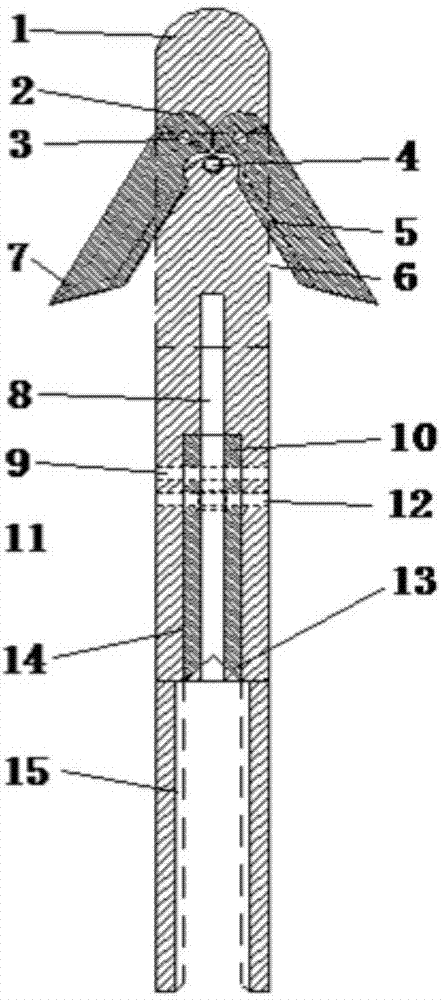

[0021] The structure of the anchor head 1 is as follows figure 1 and figure 2 shown. A bar-shaped square hole 6, 14, which is orthogonal in spatial position, is provided at the head and the middle of the anchoring head rod body, and a group of elastic self-expanding wedges are respectively installed in the two bar-shaped square holes 6, 14. Among them, the elastic self-expanding wedge installed at the head position includes an inverted V-shaped spring 5 fixed on the anchor head rod body through a spring fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com