Graphene-based stone foamed lightweight wall plate and preparation method thereof

A lightweight wallboard, graphene technology, applied in the direction of clay products, ceramic products, other household appliances, etc., can solve the problem of wear resistance, weather resistance, high temperature resistance, heat insulation, sound insulation, waterproof and impermeability. Good improvement, complex operation procedures, expensive raw materials and other problems, to achieve the effect of being beneficial to ecological environment protection, overcoming fear of open fire, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

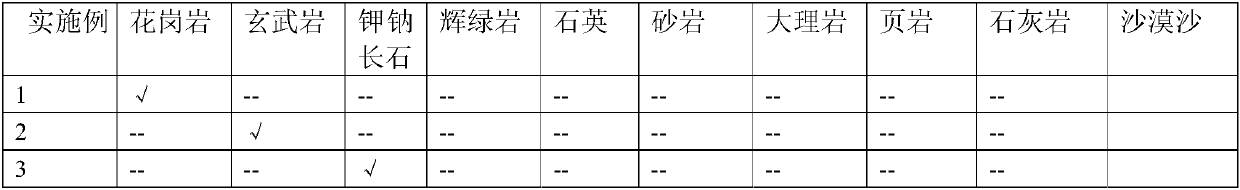

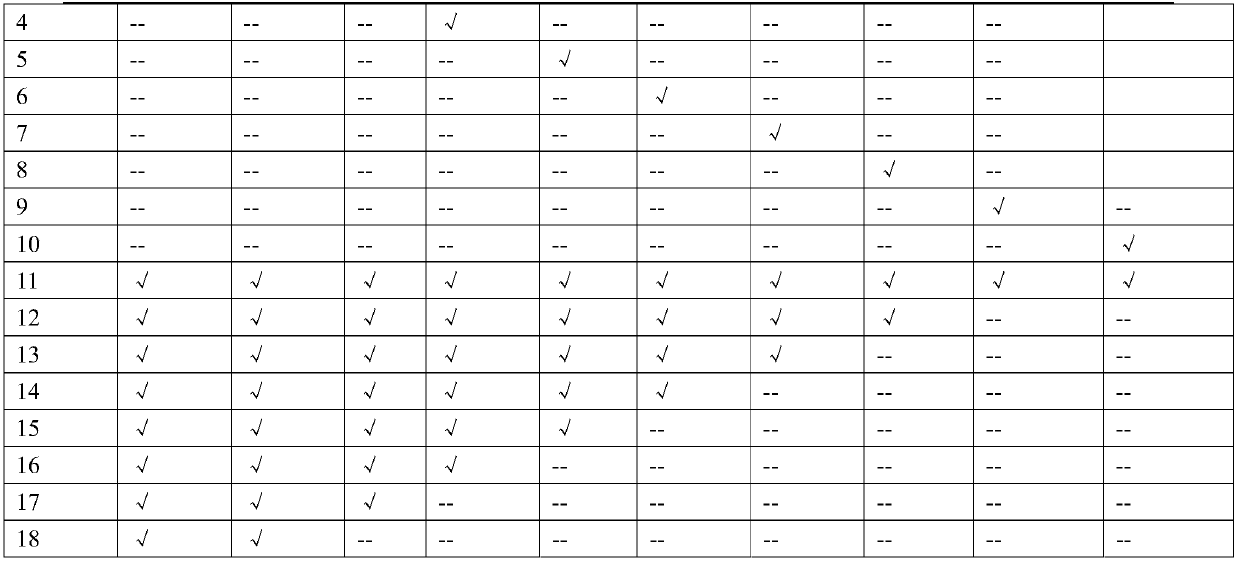

[0031] 1. The ratio of raw materials is shown in Table 1;

[0032] The stone tailings are shown in Table 2;

[0033] Described clay is see table 3;

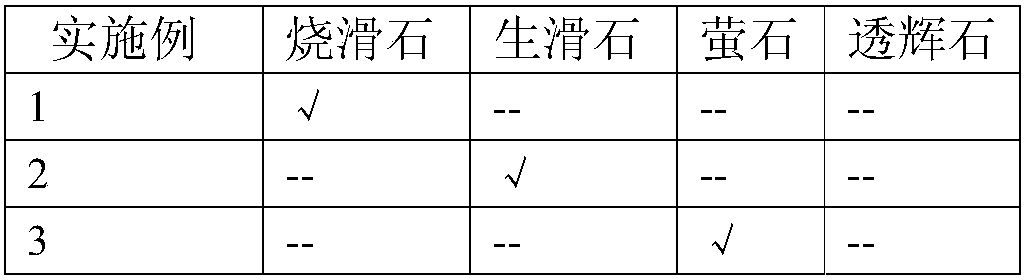

[0034] The high-temperature flux is shown in Table 4;

[0035] The stabilizers are yttrium oxide and cerium oxide.

[0036] 2. Preparation:

[0037] The specific method of preparing the foamed lightweight wallboard from the above-mentioned proportioning raw materials includes the following steps:

[0038] S1. Ore washing: crush the stone tailings and pass through 1 mesh, then send the crushed stone tailings into the immersion pool. The high-pressure water pipe installed above the inner side of the feed port is sent into the stone tailings, and at the same time, the ammonium oxalate solution with a mass concentration of 1.5% is sprayed and wetted until the volume of the sprayed ammonium oxalate solution is 1.1 times the volume of the stone tailings After that, the spraying process can be stopped, soaked for 30 minutes, and th...

Embodiment 2

[0044] 1. The ratio of raw materials is shown in Table 1;

[0045] The stone tailings are shown in Table 2;

[0046] Described clay is see table 3;

[0047] The high-temperature flux is shown in Table 4;

[0048] The stabilizers are yttrium oxide and cerium oxide.

[0049] 2. Preparation:

[0050] The specific method of preparing the foamed lightweight wallboard from the above-mentioned proportioning raw materials includes the following steps:

[0051] S1. Ore washing: crush the stone tailings and pass through 10 meshes, then send the crushed stone tailings into the immersion pool. The high-pressure water pipeline set above the inner side of the material port is sending the stone tailings into the stone tailings, and at the same time, the ammonium oxalate solution with a mass concentration of 5.5% is sprayed and wetted until the volume of the sprayed ammonium oxalate solution is 1.32 times the volume of the stone tailings After that, the spraying process can be stopped, s...

Embodiment 3

[0057] 1. The ratio of raw materials is shown in Table 1;

[0058] The stone tailings are shown in Table 2;

[0059] Described clay is see table 3;

[0060] The high-temperature flux is shown in Table 4;

[0061] The stabilizer is yttrium oxide.

[0062] 2. Preparation:

[0063] The specific method of preparing the foamed lightweight wallboard from the above-mentioned proportioning raw materials includes the following steps:

[0064] S1. Ore washing: crush the stone tailings and pass through 4 meshes, then send the crushed stone tailings into the immersion pool. The high-pressure water pipe installed above the inner side of the feed port is sent into the stone tailings, and at the same time, the ammonium oxalate solution with a mass concentration of 2.5% is sprayed and wetted until the volume of the sprayed ammonium oxalate solution is 1.21 times the volume of the stone tailings After that, the spraying process can be stopped, soaked for 60 minutes, and the material is stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com