Prefabricated type tunnel foot-lock anchors rod and steel frame connecting member

A technology for locking foot bolts and connecting components, which is applied in tunnels, tunnel lining, bolt installation, etc., can solve the problems of poor connection between the tunnel support steel frame and the foot locking bolts, and achieve engineering value and social benefits. Significantly, enhance the overall stability, the effect of simple and quick construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

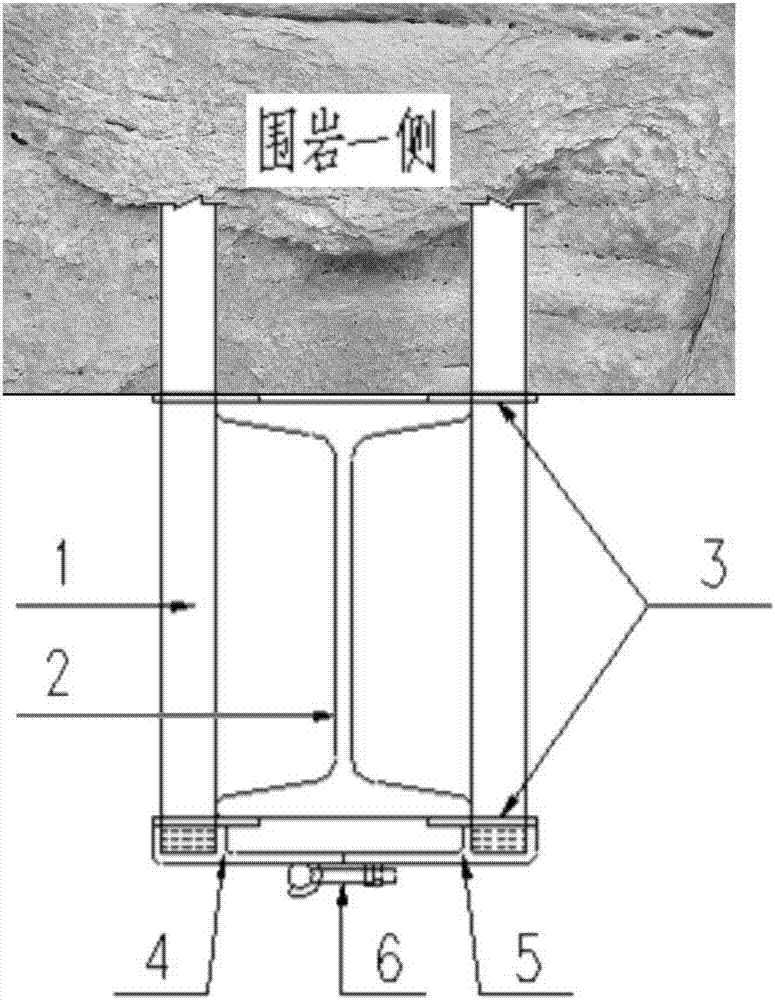

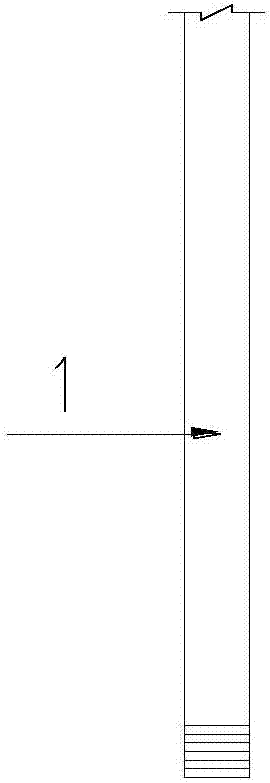

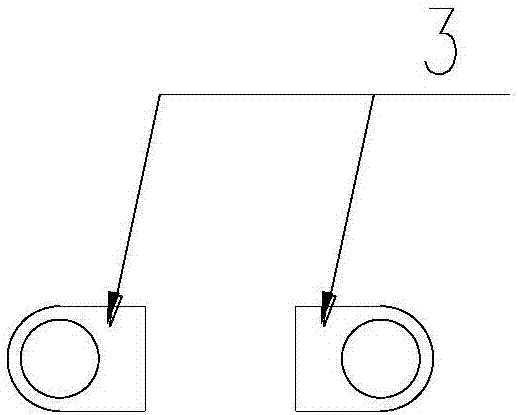

[0025] Example: such as Figure 1~Figure 7 As shown, a prefabricated tunnel lock-foot anchor rod and steel frame connecting component of the present invention consists of the lock-foot anchor rod 1, the supporting steel frame 2, the positioning ring piece 3, the left bolt sleeve 4, and the right bolt sleeve 5. Composed of 6 bolt fasteners. In the preparation stage, firstly perform thread processing pretreatment on the end of the lock foot anchor 1 (the side connected to the steel frame); secondly, according to the design position and construction angle of the lock foot anchor 1, weld the positioning ring 3 to the support The corresponding position of steel frame 2. In the construction stage, the lock foot anchor rod 1 is accurately positioned and constructed by the supporting steel frame 2 front and rear positioning ring pieces 3, and then the prefabricated left bolt sleeve 4, right bolt sleeve 5, and bolt fastener 6 are used to support the steel frame 2 Lock foot anchor rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com