High-ductility seismic insulation rubber support fireproof protection structure and construction process thereof

A technology for shock-isolation rubber and protective structures, which is applied in fire prevention, protective buildings/shelters, and earthquake resistance, and can solve problems such as partial tearing or overall tearing, inability to achieve fire prevention effects, and insufficient ductility , to achieve the effect of saving labor costs, reducing the frequency of maintenance and replacement, and the construction process is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

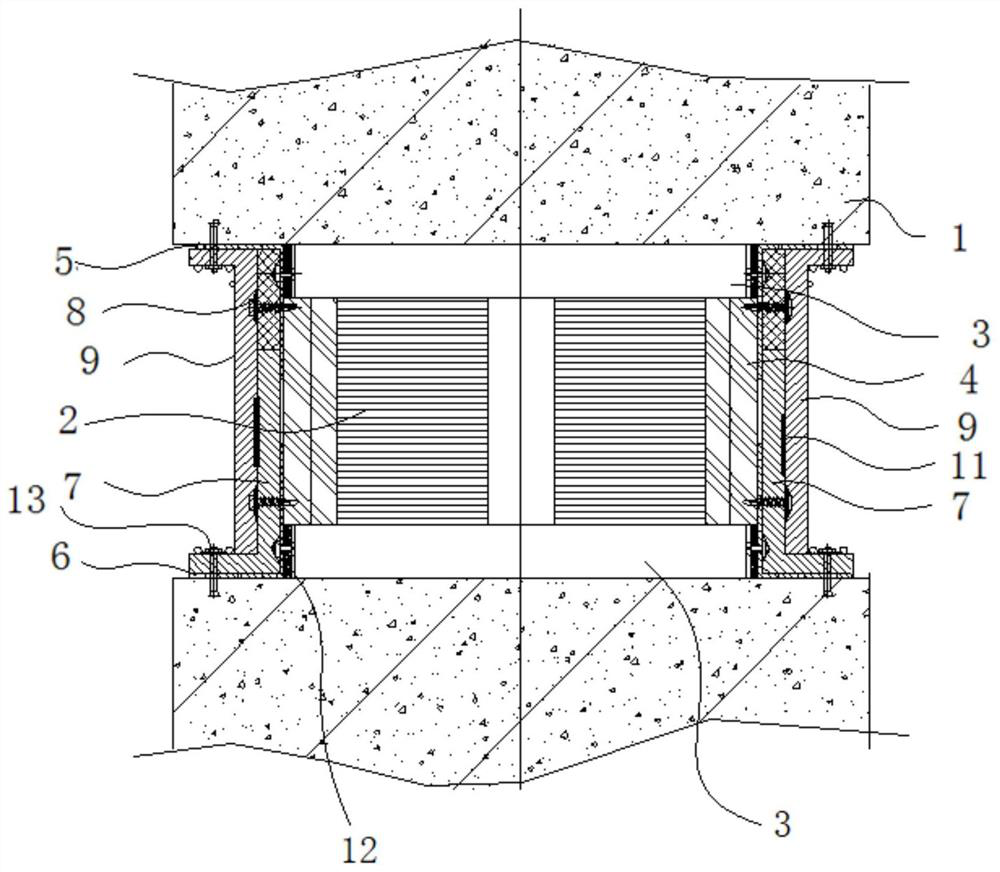

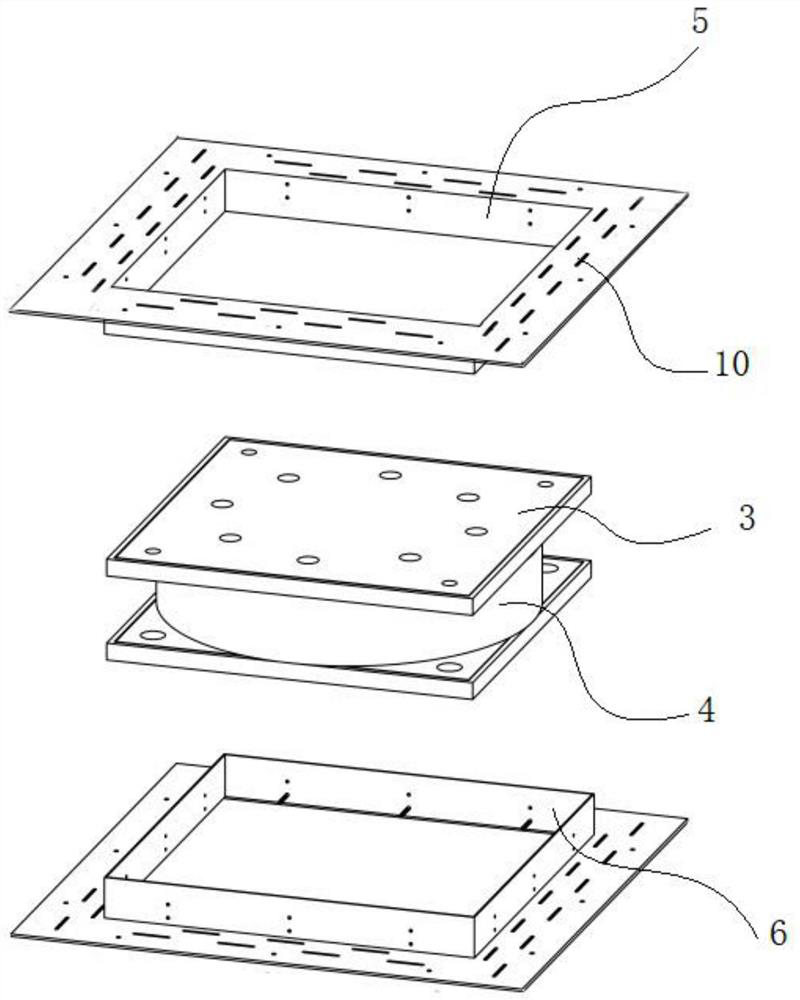

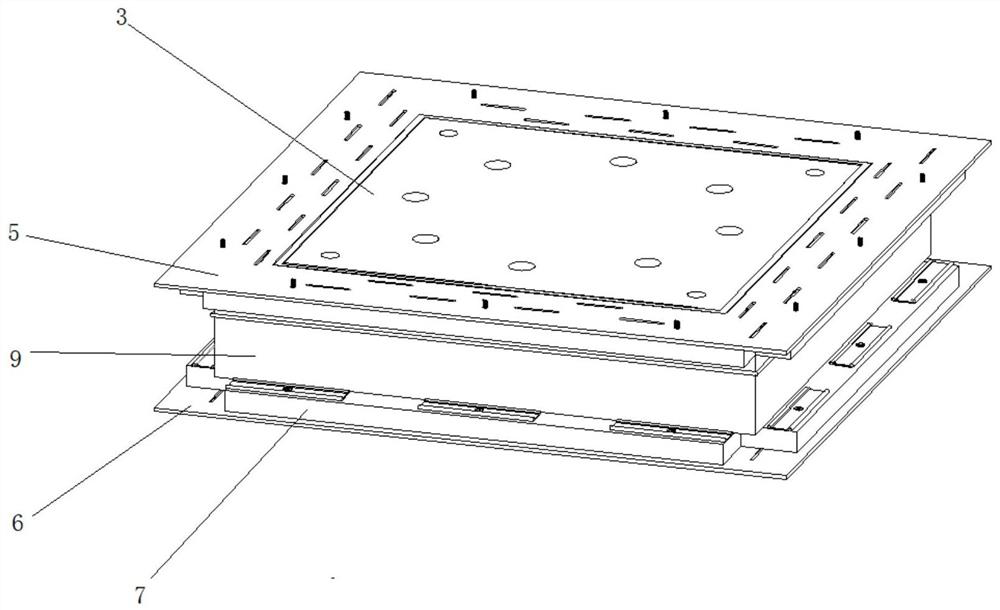

[0029] Embodiment 1: A high ductility anti-vibration rubber bearing fire protection structure, such as figure 1As shown, it includes the vibration-isolation rubber bearing 2 installed between the upper and lower pier 1, the upper and lower ends of the vibration-isolation rubber bearing 2 are installed with flange plates 3, and the flange plate 3 is connected to the vibration-isolation rubber bearing 2 The outer layer is wrapped with a flexible fireproof and heat-insulating material 4, and a high-extensibility fireproof structure layer is installed on the periphery of the shock-absorbing rubber support 2 and the flexible fireproof and heat-insulation material. It consists of two parts, the upper connecting fixed plate 5 and the lower connecting fixed plate 6, which are respectively installed on the inner walls of the upper and lower buttresses, and extend along the inner wall surface to the vibration-isolation rubber bearing 2 in an attached manner to a flexible fire-proof and h...

Embodiment 2

[0033] Embodiment 2: on the basis of the scheme of embodiment 1, as Figure 8 , Figure 9 As shown, the structure between the inner and outer fireproof composite layers is improved, the inner and outer fireproof composite layers are connected in one piece, and the extension sections formed by folding or bending structures between the inner and outer fireproof composite layers are mutually connect.

[0034] The inner layer fireproof composite layer 7 and the outer layer fireproof composite layer 9 are integrated structures, and then install and fix the fireproof composite layer 8 and then install them synchronously: the inner layer fireproof composite layer 7 is pasted upward along the lower surface and the side surface of the fixed plate 6 at the lower part The flexible fire-proof and heat-insulating material 4 is installed until it touches the fixed fire-proof composite layer 8, then bent and extended until the bottom and then bent upwards to form the outermost outer fire-pr...

Embodiment 3

[0036] Example 3: On the basis of Example 1, the structure between the inner and outer fireproof composite layers is improved, the relative height of the outer fireproof composite layer 9 is greater than the height of the inner fireproof composite layer 7, and the outer fireproof composite layer The bottom of the layer 9 continues to bend upwards at least twice and then is distributed downwards, so that the lower half of the outer fireproof composite layer 9 is arranged in an S-shaped multi-layer fold. Such a structure makes the outer fireproof composite layer 9 During the large deformation process, the extension of the fireproof composite layer can be realized according to the direction and degree of deformation displacement, and tear damage can be avoided, while the inner fireproof composite layer 7 still provides complete protection for the shock-isolation rubber bearing 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com