Gap sealing structure between curtain wall and floor structure and its construction method

A floor structure and closed structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems that affect the quality requirements of houses, hidden dangers in quality and safety, poor appearance effects, etc., to ensure reliability and durability, ensure Safe to use, fireproof and windproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

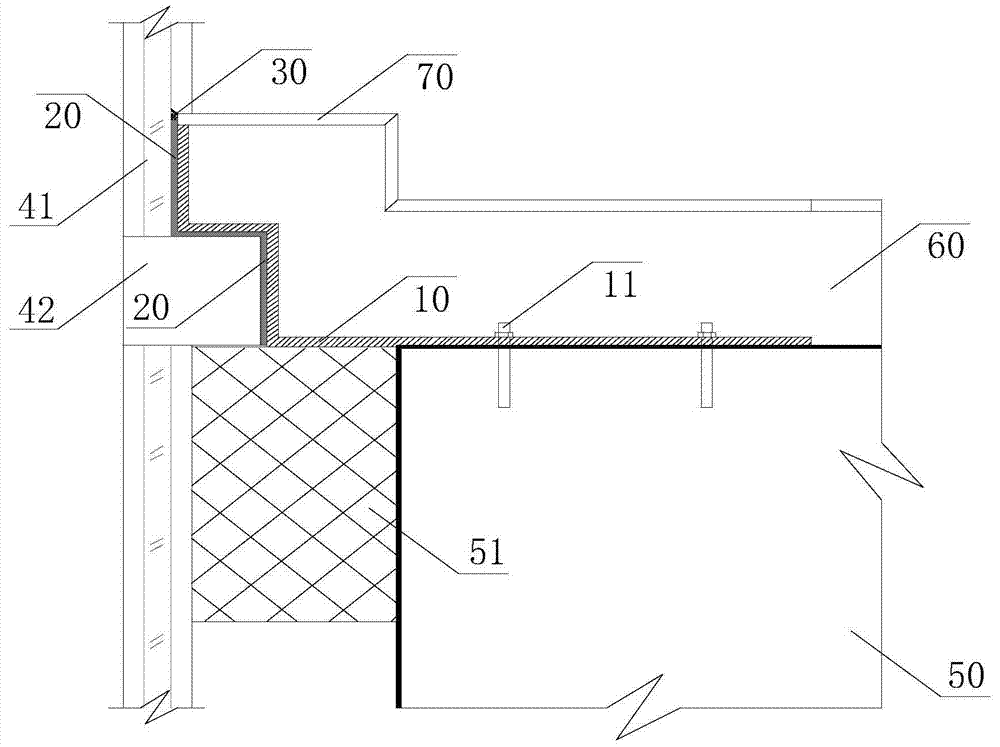

[0024] The present invention provides a gap sealing structure between the curtain wall and the floor structure, please refer to figure 1 , comprising a cantilevered folded galvanized steel sheet 10, said cantilevered folded galvanized steel sheet 10 is bent and formed along the inner surfaces of curtain wall glass 41, curtain wall window frame 42 and floor structure 50, said cantilevered folded galvanized steel sheet 10, the curtain wall glass 41 and the curtain wall window frame 42 are provided with a rubber-plastic insulation board 20, and the cantilevered folded galvanized steel plate 10 is successively laid with a construction layer 60 and a finish layer 70, and the finish lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com