Novel fireproof door and window system

A new type of technology for doors and windows, applied in the field of fireproof windows, can solve the problems of complex manufacturing process, poor customization conditions, and low overall strength, and achieve the effects of mature production technology, low production cost, and improved aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

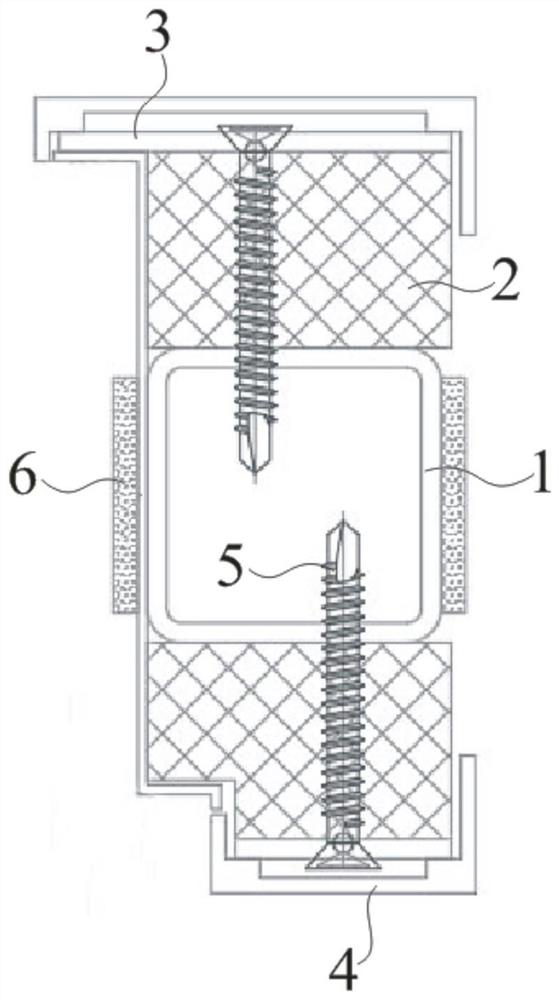

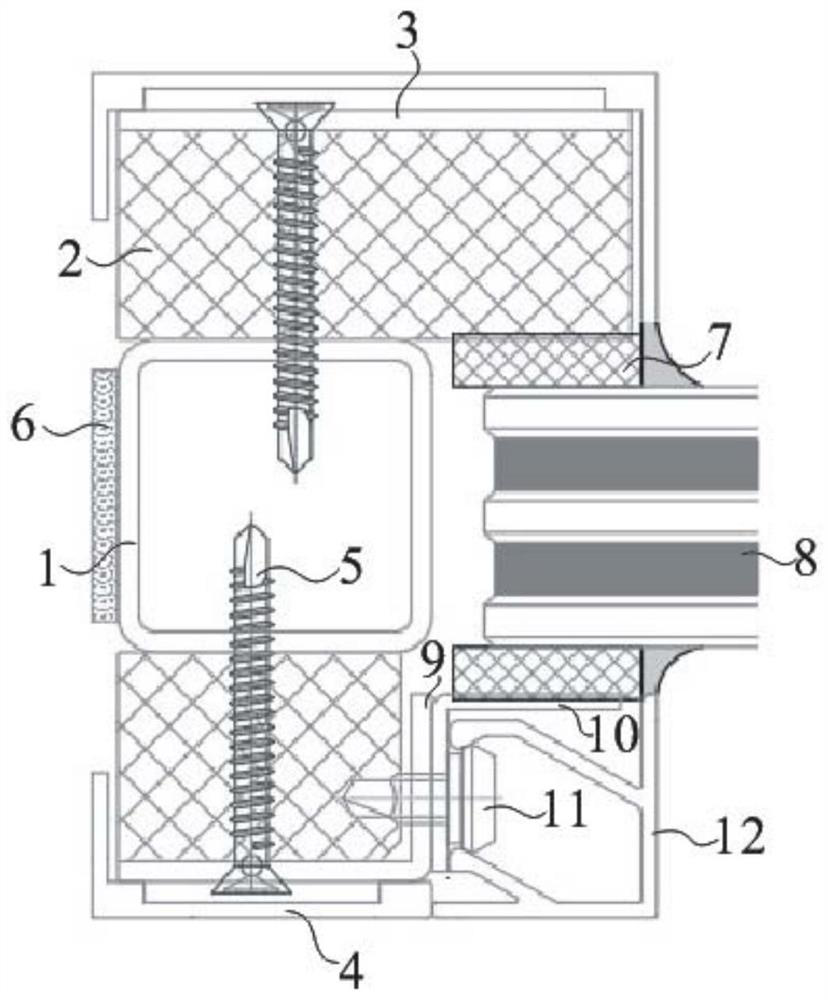

[0027] As shown in the figure, a new fireproof door and window system according to the present invention includes a door frame installation part and a door leaf installation part. The door frame installation part includes a door frame surrounded by an installation unit, and the installation unit includes a galvanized square Pipe 1, the fire-proof and heat-insulating material 2 arranged on both sides of the galvanized square pipe 1, and the galvanized steel plate arranged on the end of the fire-proof and heat-insulated material 2 away from the galvanized square pipe 1 and fixedly connected with the galvanized square pipe 1 through bolts 5 3. The door leaf installation part includes a fan frame surrounded by the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com