Assembly type cast-in-place concrete exterior thermal insulation wall steel skeleton framework system and connecting piece

A concrete and external thermal insulation technology, applied to walls, building components, buildings, etc., can solve the problems of not being able to enter the construction market, high construction costs, and long construction periods, so as to ensure the overall construction quality, improve the overall construction speed, and improve the construction process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples describe the present invention in more detail.

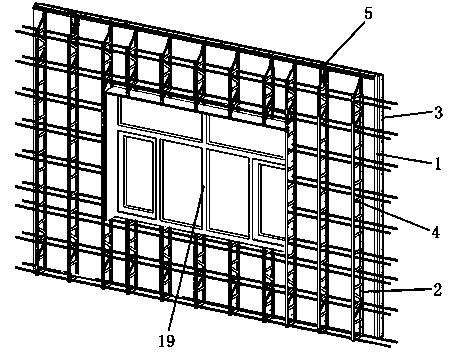

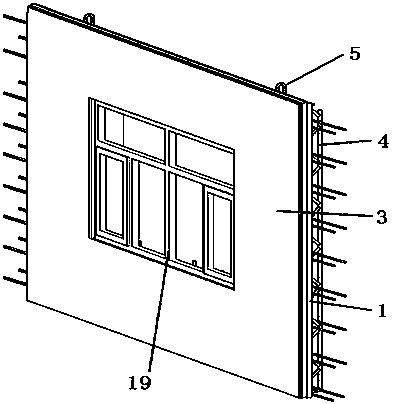

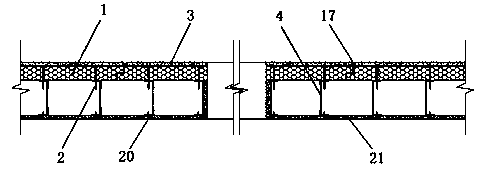

[0033] combine Figure 1~Figure 8 , the first embodiment of the present invention includes a thermal insulation layer 1, the thermal insulation layer is composed of thermal insulation modules (boards) tongue and groove plug-in assembly, each thermal insulation module (board) is fixed on one side of the angle steel truss 4 through connectors 2 . A thin plastering protection layer 3 is arranged outside the insulation layer, and a sealant groove 17 is arranged on the edge of the protection layer. There are cutouts 18 overlapping each other on the sides of the thermal insulation module (board). The other side of the angle steel truss is fixedly installed with screws or bolts 20 without removing the cement board or support formwork 21 to form the cavity of the concrete load-bearing wall. The angle steel truss of the present invention is composed of two parallel angle steels 6, 7 and a strip steel 8 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com