Construction method for two-block unballasted track bed board

A technology of ballastless track and construction method, which is applied in the direction of track, track laying, track maintenance, etc., and can solve the problems of huge and large project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

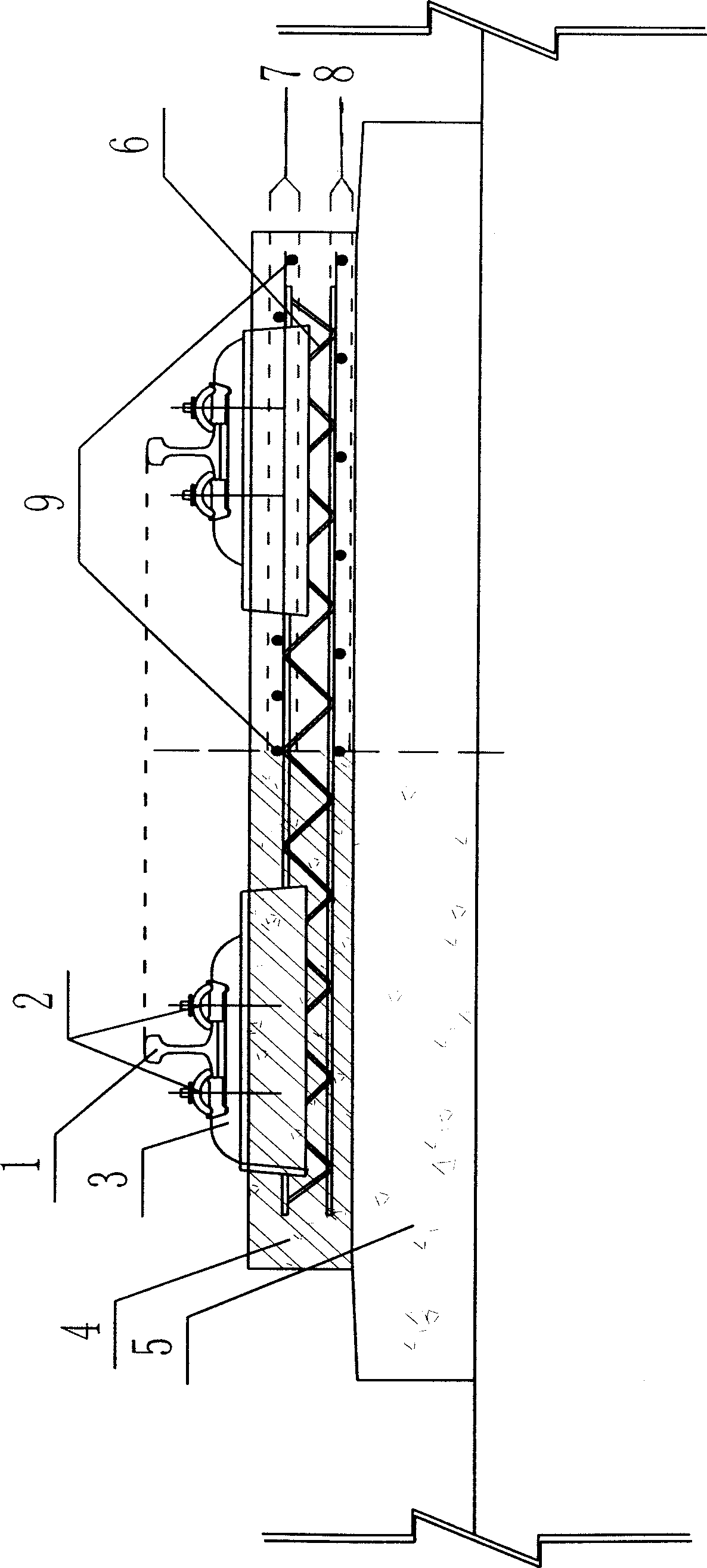

[0081] Embodiment 1: The construction method of the double-block ballastless track bed slab suitable for the roadbed section track bed slab, the steps are as follows:

[0082] The first step is to clean the base layer and set out the construction line:

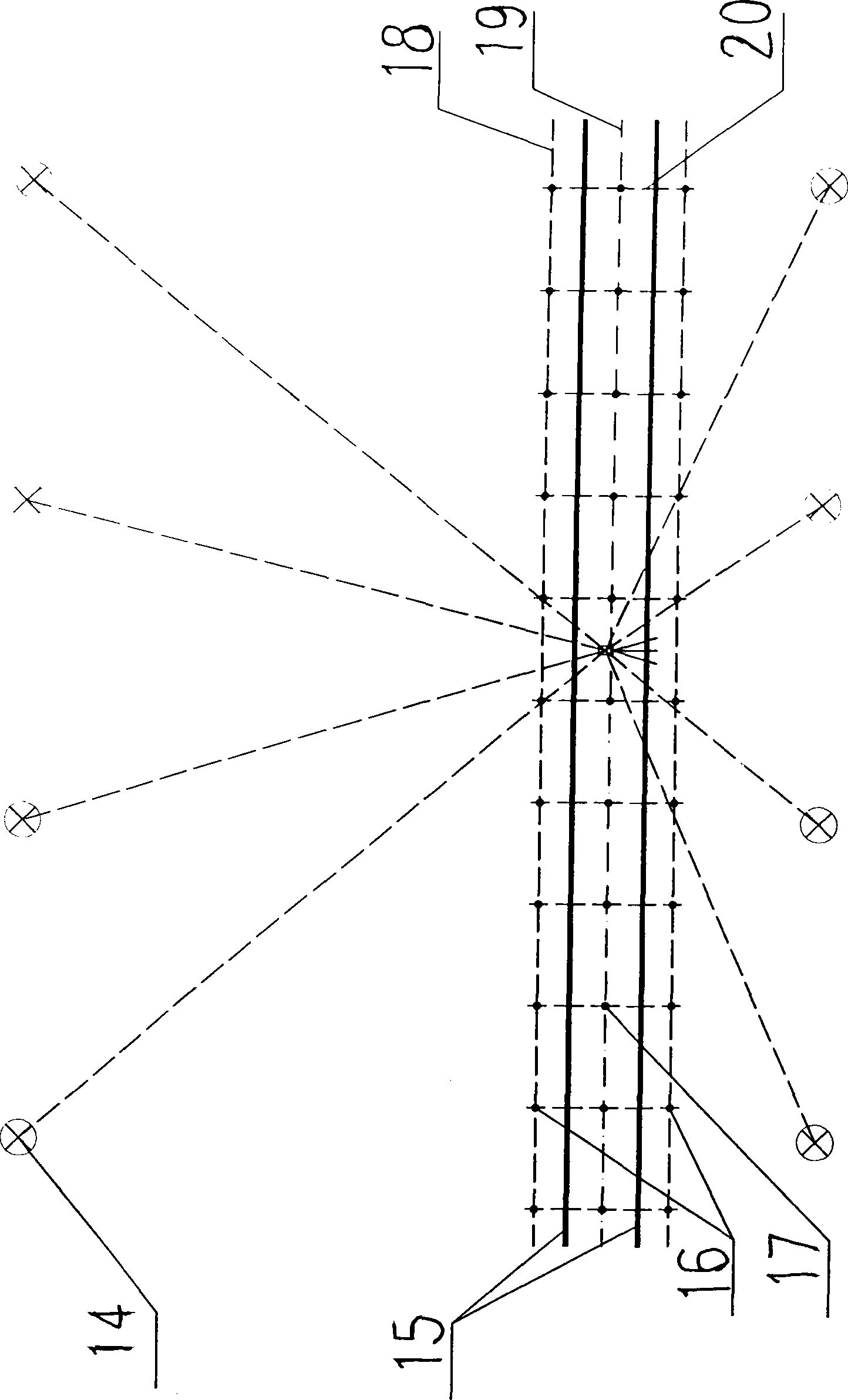

[0083] see figure 1 with figure 2 , first remove the scum, dust and sundries on the surface of the support layer 5 of the subgrade section; then carry out construction setting-out positioning on the support layer 5 according to the CPIII control point 14 of the foundation pile control network, and the distance between every about 10 sleepers— 6.4m, stake out the left and right points 16 of the template and the track center point 17, and make these three points on the same section on a straight line; then, pop up the left and right template sidelines 18 and the track centerline with ink lines according to the stakeout points 19 and sleeper axis 20;

[0084] The second step is to place the bottom reinforcement and lay the sl...

Embodiment 2

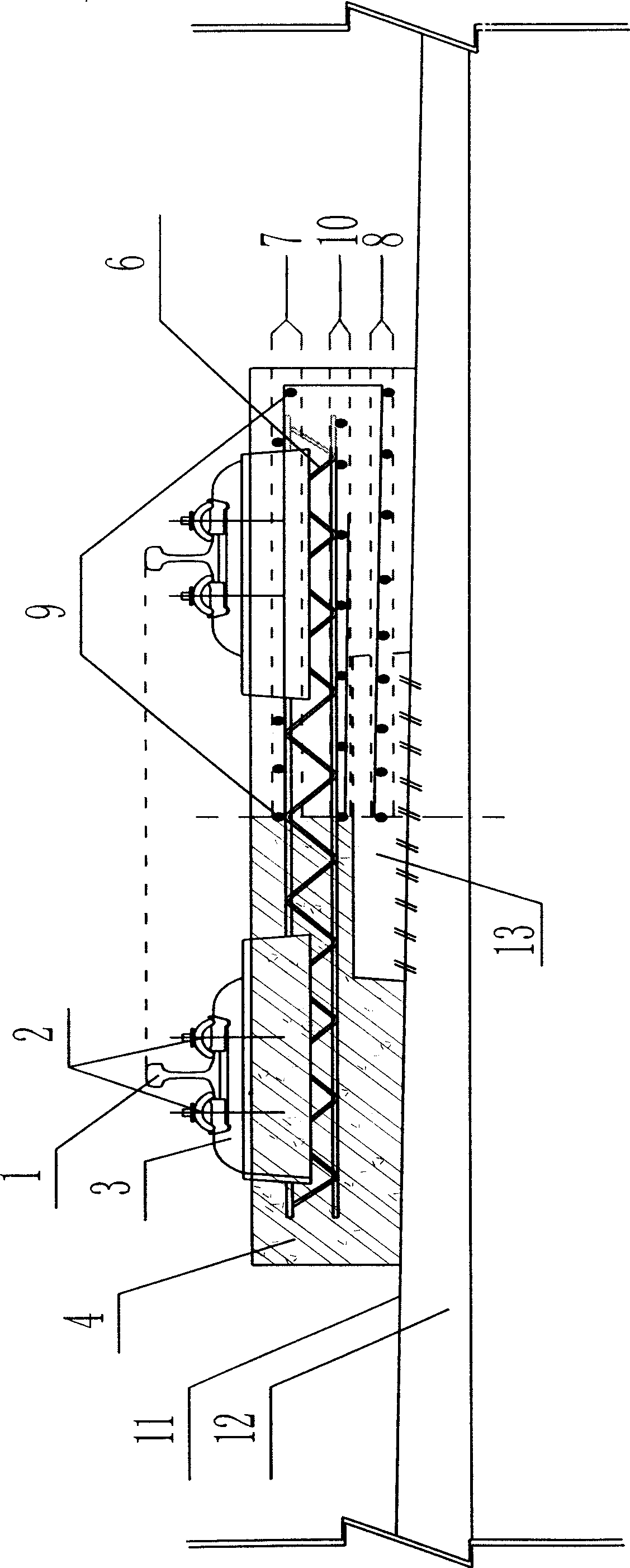

[0115] Embodiment two: the construction method that is suitable for the double-block type ballastless track bed slab of the bridge section track bed slab, its steps are as follows:

[0116] The first step is to clean the base layer and set out the construction line:

[0117] see figure 1 with image 3 , first remove the scum, dust and sundries on the surface of the bridge deck protection layer 12 of the bridge section; then according to the CPIII control point 14 of the foundation pile control network, carry out construction setting-out positioning on the middle layer 11 of the bridge, every about 10 Distance between sleepers - 6.4m, stake out the left and right points 16 of the formwork and the track center point 17, and make these three points on the same section in a straight line; then, pop up the left and right formwork sidelines 18 with ink lines according to the stakeout points , track centerline 19 and sleeper axis 20;

[0118] The second step is to place the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com