Reverse hitting preparation technology of non-facing layer prefabricated wall body

A preparation process and prefabricated technology, applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of difficult to popularize prefabricated buildings, high incremental cost, high cost, etc., and achieve simple production and production. Fast, simple and convenient construction process, and the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings.

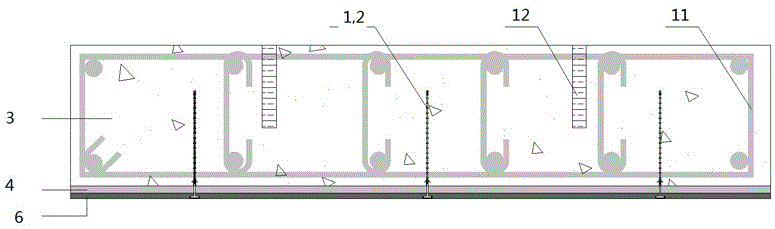

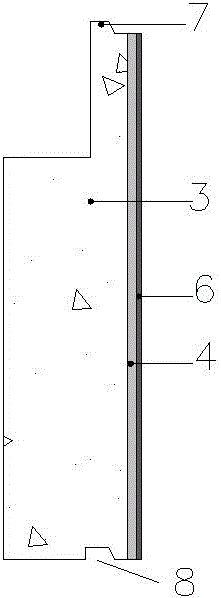

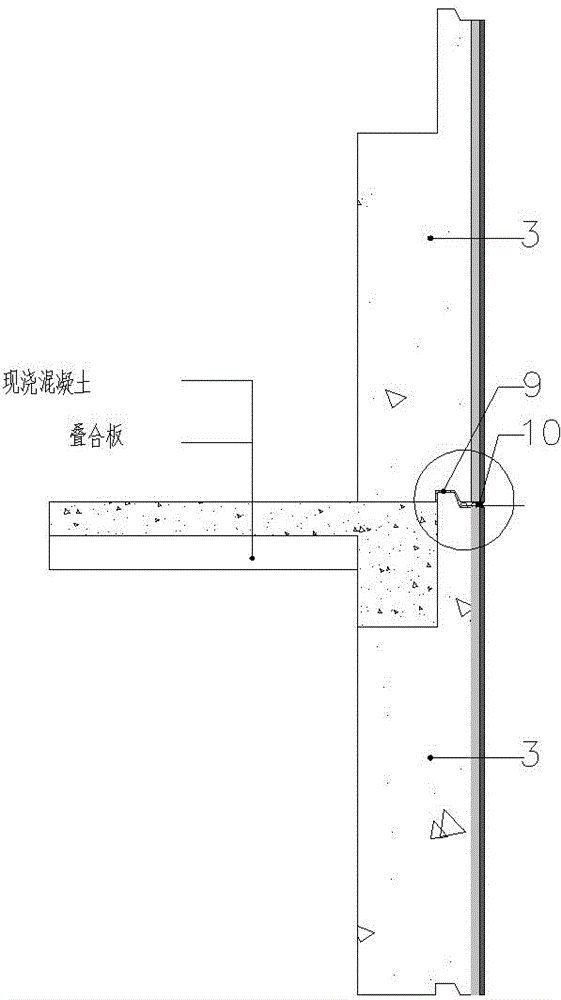

[0060] figure 1 A prefabricated self-insulating wall is shown, the wall includes a concrete wall 3, an insulation board 4, the insulation board 4 itself has a protective layer, and a cement mortar protective layer is set outside the insulation board, and the concrete wall 3 Insulation boards are provided on the outside.

[0061] The self-protective layer of the insulation board can be cement mortar or paste cement sheet or calcium silicate board, glass magnesium board, cement fiber thin felt.

[0062] figure 1 It shows the horizontal structure of the wall, that is, the schematic diagram of the preparation of the anti-strike method. In fact, the wall is vertical when it is installed.

[0063] Preferably, the insulation material 4 of the insulation board is a vacuum insulation board.

[0064] The present invention further discloses a construction method of back-beati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com