Allocation and Method of Retrofitting Existing Oxidation Tank to Recover Anodic Oxidation Solution

A technology of anodizing and oxidizing liquid, applied in anodizing, coating, electrolytic components, etc., can solve problems such as increasing equipment investment, and achieve the effect of reducing investment cost, avoiding ash hanging, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

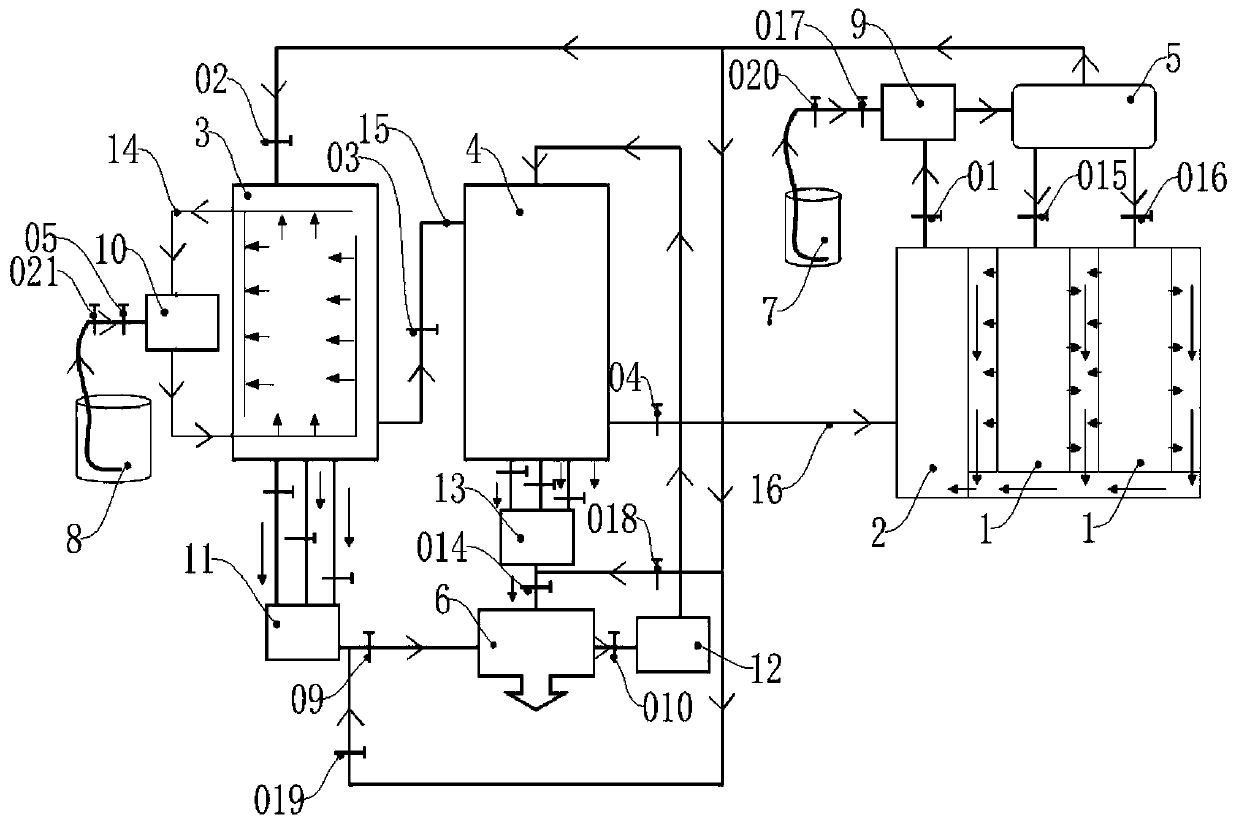

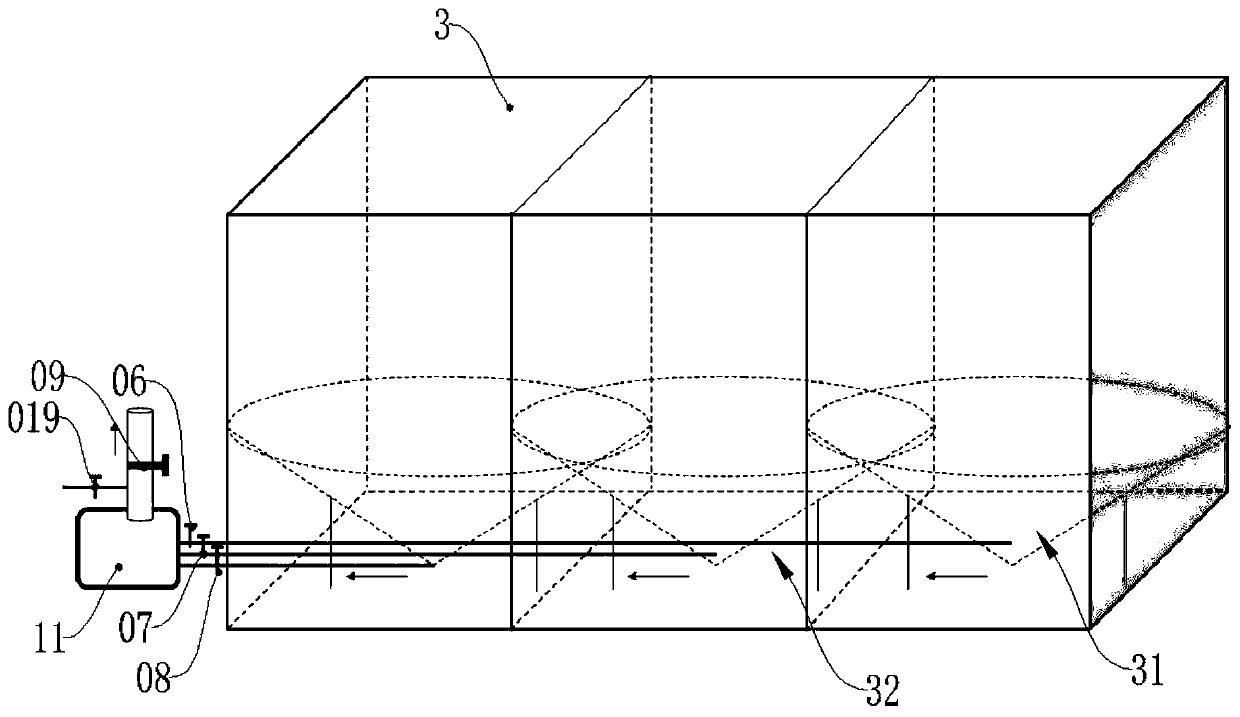

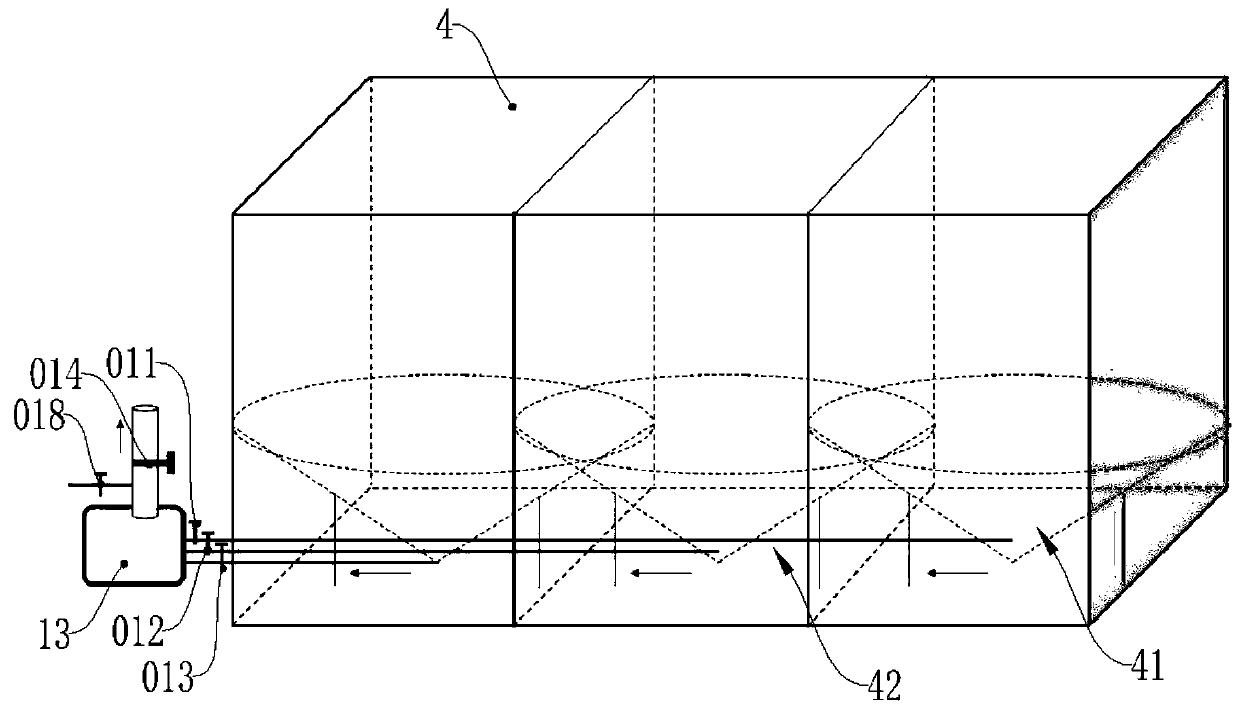

Method used

Image

Examples

Embodiment Construction

[0064] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention is described in detail below, but it should not be construed as limiting the scope of implementation of the present invention.

[0065] 1. Theoretical basis for the recovery of aluminum ions and sulfuric acid in the anodizing solution

[0066] When the aluminum alloy is oxidized, according to formula (3), part of the oxide film is dissolved, about 4Kg / T (400m 2 ) of aluminum is dissolved into the sulfuric acid oxidation solution, so that the oxidation solution contains Al 3+ 、H + and SO 4 2- , add ammonium sulfate, ammonium nitrate, ammonium chloride, potassium sulfate, potassium nitrate, potassium chloride to this oxidation solution, then the following reaction occurs:

[0067] Add ammonium sulfate to the oxidizing solution:

[0068] al 2 (SO 4 ) 3 +(NH 4 ) 2 SO 4 +12H 2 O=2NH 4 Al(SO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com