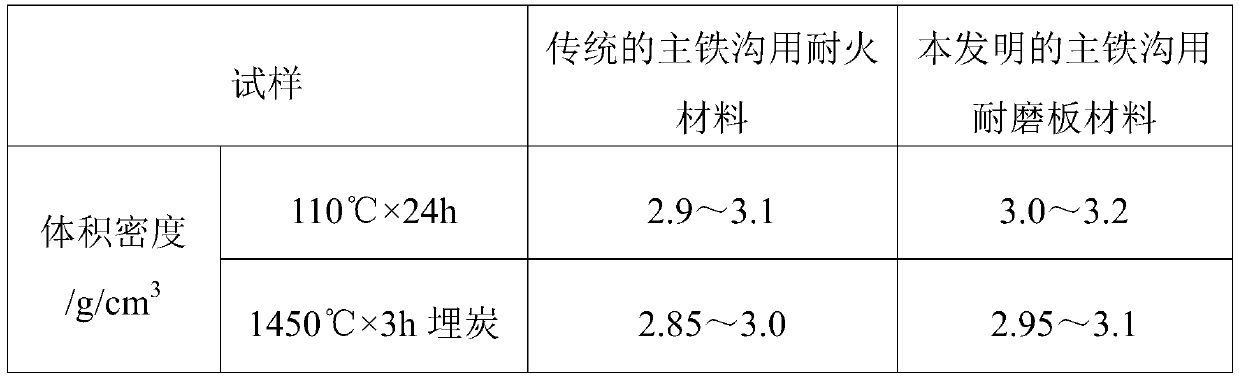

Nano-sol combined wear-resistant board used for main iron channel of blast furnace and production method and application thereof

A nano-sol and wear-resistant plate technology, which is applied in the field of refractory materials for blast furnace ironmaking, can solve the problems of poor slag iron erosion and wear resistance, reduced service life of the main iron trench, and affecting normal production of blast furnaces, etc., to achieve good oxidation resistance , Improve the erosion resistance and strengthen the combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 5

[0049] In Example 1-Example 5, each component of the non-oxidized composite powder was weighed in parts by weight shown in Table 2, poured into an inclined mixer and mixed, the rotor speed was controlled at 150-180r / min, and the mixing time Control it for 3 to 5 minutes, and put it into a waterproof packaging bag after mixing and seal it for storage.

[0050] The composition of the non-oxide composite powder of table 2 embodiment 1-embodiment 5

[0051] name

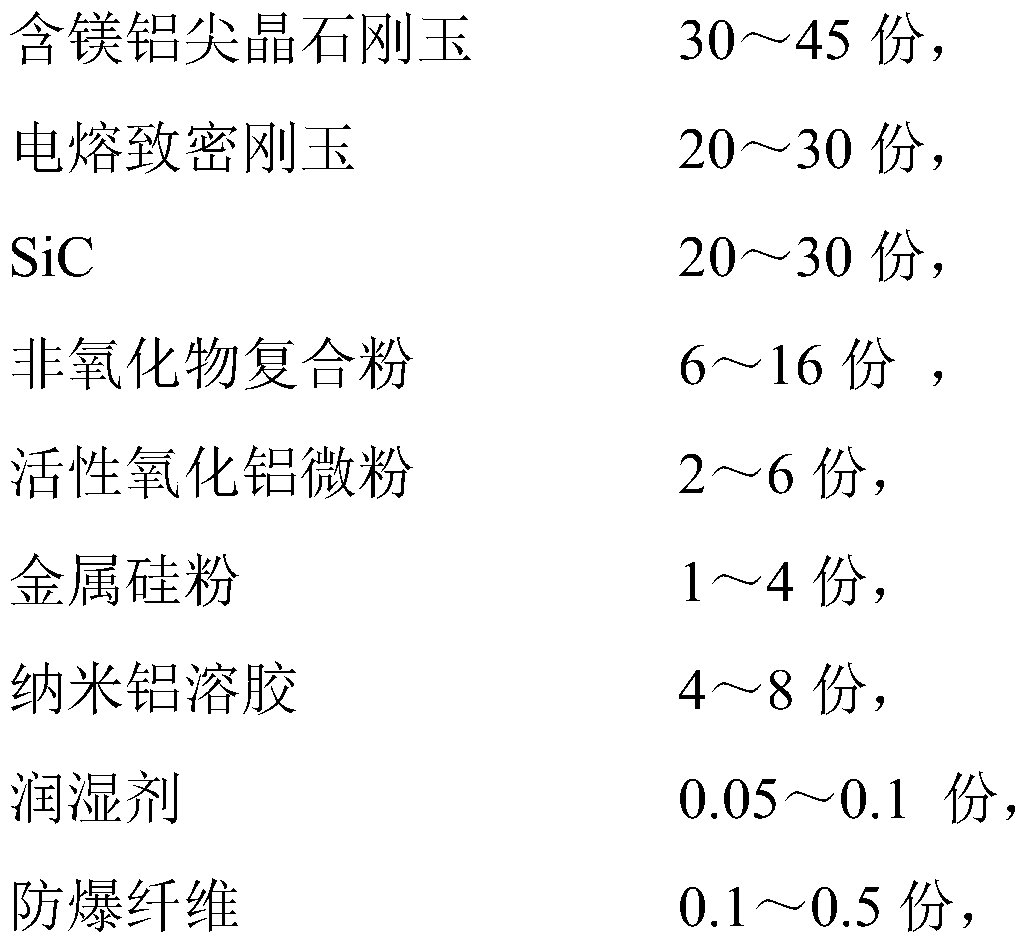

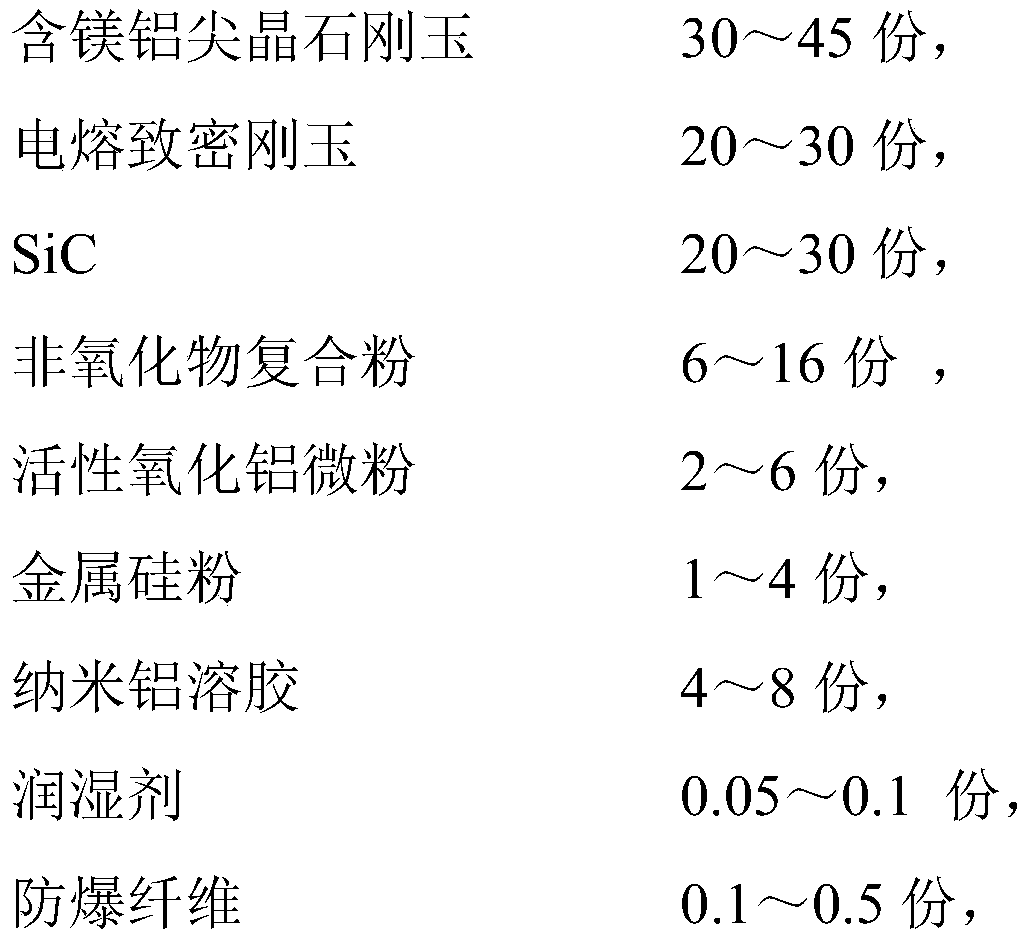

[0052] 3. Nano-sol combined with long-life environmental protection wear-resistant plate prepared by non-oxidizing composite powder

preparation example 1

[0054] Its components and parts by weight are: 35 parts of magnesium-aluminum spinel corundum; 25 parts of fused dense corundum; 25 parts of SiC; 8 parts of non-oxide composite powder prepared in Example 1 above; 5 parts of activated alumina micropowder , 2 parts of metal silicon powder, 6 parts of nano aluminum sol, 0.05 part of wetting agent, 0.2 part of explosion-proof fiber,

[0055] Among them, the gradation of magnesium-aluminum spinel corundum is 8mm-5mm 10 parts; 5mm-3mm 15 parts, 3mm-1mm 10 parts.

[0056] Among them, the gradation of fused dense corundum is 1mm-0.2mm, 15 parts; the particle size is ≤0.074mm, and 10 parts.

[0057] Weigh each component of the wear-resistant plate raw material according to its weight, pour it into the mixer and stir for 5 minutes, adjust the amount of nano-alumina sol to make the vibration fluidity reach 130-140mm, and then pour it into the corresponding wear-resistant plate mold. Use a vibrating rod to tamp the air holes, release the...

preparation example 2

[0059] Its components and parts by weight are: 35 parts of magnesium-aluminum spinel corundum; 24 parts of fused dense corundum; 25 parts of SiC; 11 parts of non-oxide composite powder prepared in Example 2 above; 3 parts of activated alumina micropowder , 2 parts of metal silicon powder, 7 parts of nano aluminum sol, 0.06 parts of wetting agent, 0.2 parts of explosion-proof fiber,

[0060] Among them, the gradation of magnesium-aluminum spinel corundum is 8mm-5mm 10 parts; 5mm-3mm 15 parts, 3mm-1mm 10 parts.

[0061] Among them, the gradation of fused dense corundum is 1mm-0.2mm, 10 parts; the particle size is ≤0.074mm, and 14 parts.

[0062] Weigh each component of the wear-resistant plate raw material according to its weight, pour it into the mixer and stir for 5 minutes, adjust the amount of nano-alumina sol to make the vibration fluidity reach 130-140mm, and then pour it into the corresponding wear-resistant plate mold. Use a vibrating rod to tamp the air holes, release ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com