Method for preparing laminated ceramic nozzle based on stress wave theory

A ceramic nozzle and stress wave technology, applied in spray guns, manufacturing tools, metal processing equipment, etc., can solve the problems of large wear at the nozzle inlet and outlet, reduce the service life of ceramic nozzles, etc. Erosion wear resistance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

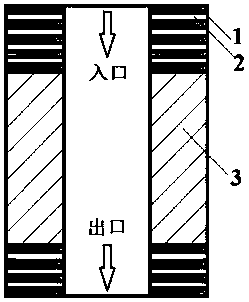

[0016] Embodiment one: according to 85%B 4 C +13%TiC +2%Y 2 o 3 and 88%B 4 C +10% Al 2 o 3 +2%Y 2 o 3 The mass ratio of the laminated material is weighed, 40%B 4 The mass ratio of C+60%WC-Co is weighed to take the material of the middle layer of the nozzle; the weighed mixed powder is respectively used as the medium of deionized water and alumina as the grinding ball for planetary strengthening ball milling for 150 h. Dry in a vacuum oven, and pass the mixed powder through a 200-mesh sieve. Calculate the mass of each layer according to the mixing theoretical density, layer thickness, and inner and outer diameters of the nozzles of each laminated material, according to figure 1 The stacking sequence and the number of layers shown are flattened in the graphite mold, the layers are pre-pressed and placed in a vacuum sintering furnace, the sintering temperature is 1850°C, the sintering pressure is 32MPa, and the sintering holding time is 50min; the sintered laminated ceram...

Embodiment 2

[0017] Embodiment two: other is with embodiment one, difference is according to 90%B 4 C +8% TiC +2% Y 2 o 3 and 83%B 4 C+15%Al 2 o 3 +2%Y 2 o 3 The mass ratio of the laminated material is weighed, 30%B 4 The mass ratio of C+70%WC-Co weighs the material of the middle layer of the nozzle; the sintering temperature is 1880°C, the sintering pressure is 35MPa, and the sintering holding time is 55min; the Vickers hardness at the inlet and outlet of the sintered laminated ceramic nozzle material is 27.5~28.2GPa , The equivalent bending strength of the overall front of the nozzle is 750~877MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com