A coating device for single-wheel integral blisk of axial-flow compressor

A technology of integral blisk and coating device, which is applied in the direction of coating, metal material coating process, vacuum evaporation coating, etc., and can solve the problems of sand entrainment, water drop impact, wear and corrosion, and difficulty in blade protection, etc. problems, to achieve significant economic benefits, improve reliability and service life, and improve the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

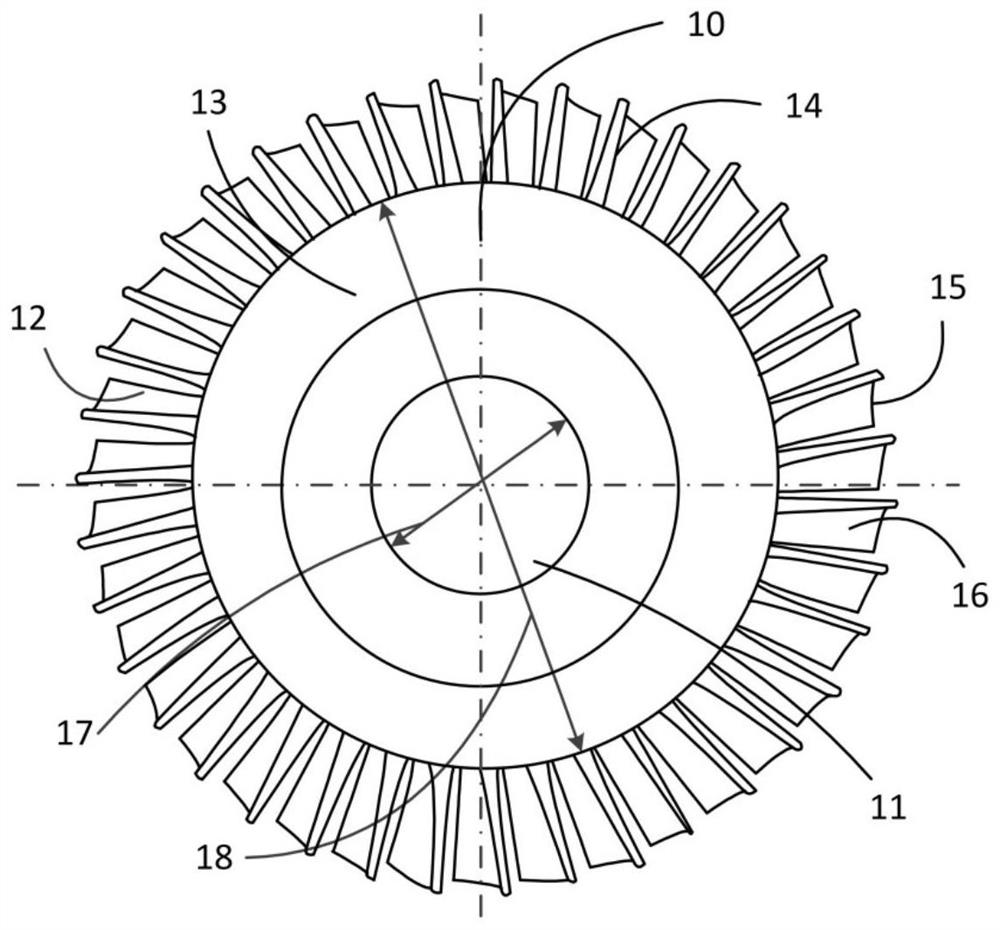

[0025] According to the structural characteristics of the axial-flow single-wheel integral blisk, the present invention provides a method for preparing a special protective coating for the single-wheel integral blisk of an axial-flow compressor. The coating prepared by the method can significantly improve the service life of the integral blisk , which is suitable for improving the impact resistance of the intake end of the single-wheel integral blisk, the wear resistance of the exhaust end and the corrosion resistance of the blade.

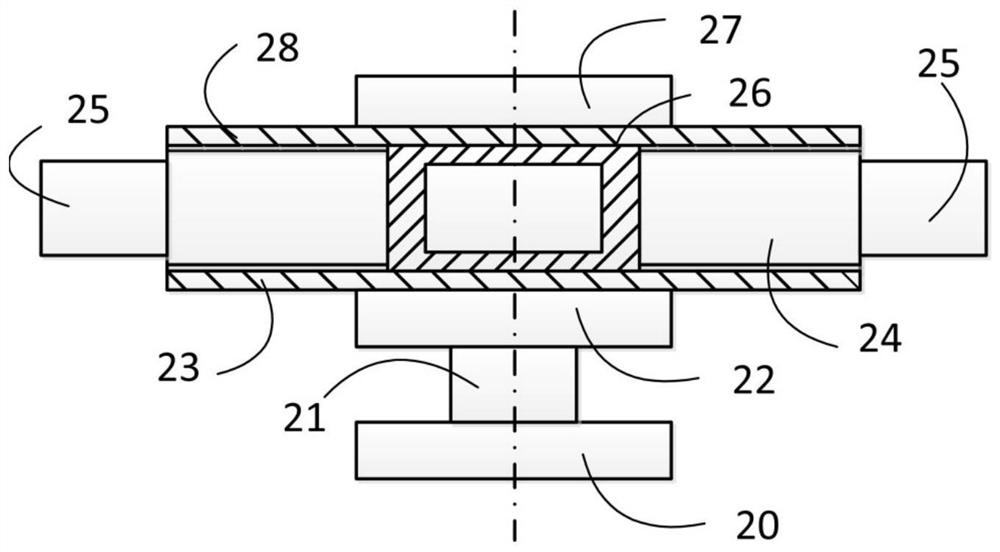

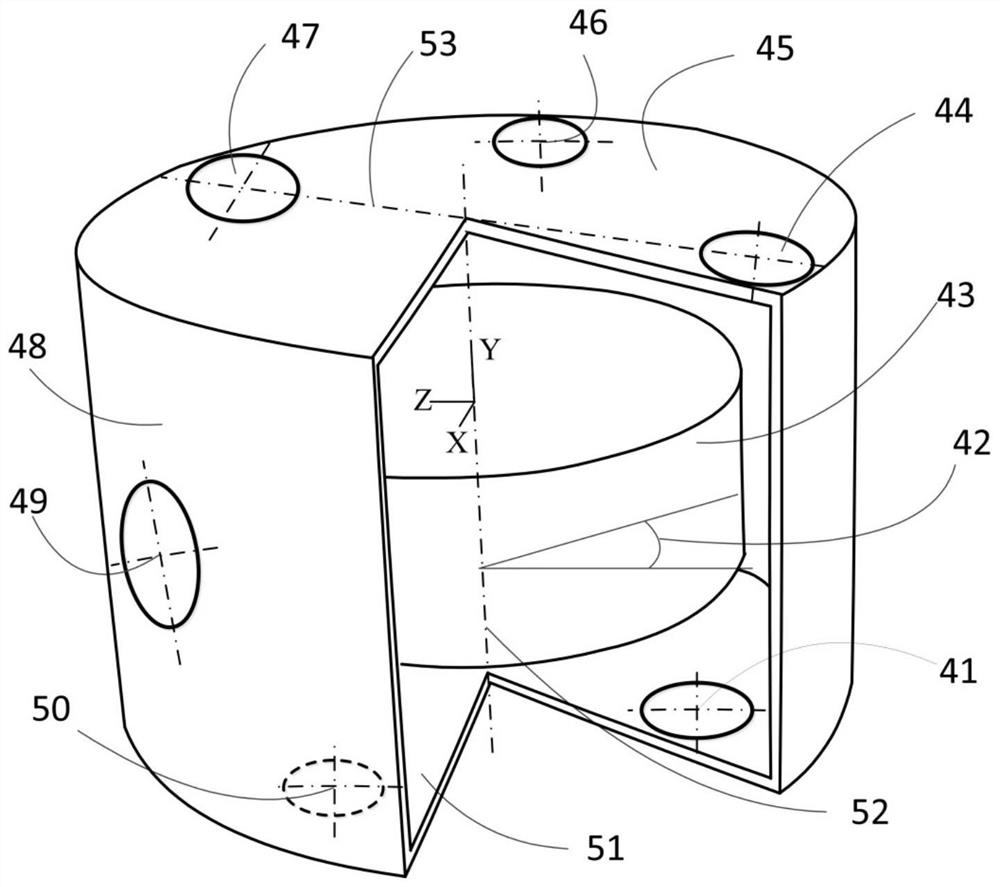

[0026] The present invention proposes a coating device for a single-wheel integral blisk of an axial flow compressor, which includes a vacuum chamber 51 and a fixture, wherein the blisk is installed in the vacuum chamber of the coating equipment through the fixture.

[0027] Four coating deposition targets and two ion implantatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com