Intelligent scheduling system and method for steelmaking production process

A technology for intelligent scheduling and production process, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as delay in grasping real-time time information, inconsistent coordination of processes before and after the production site, and achieve the effect of rapid production recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

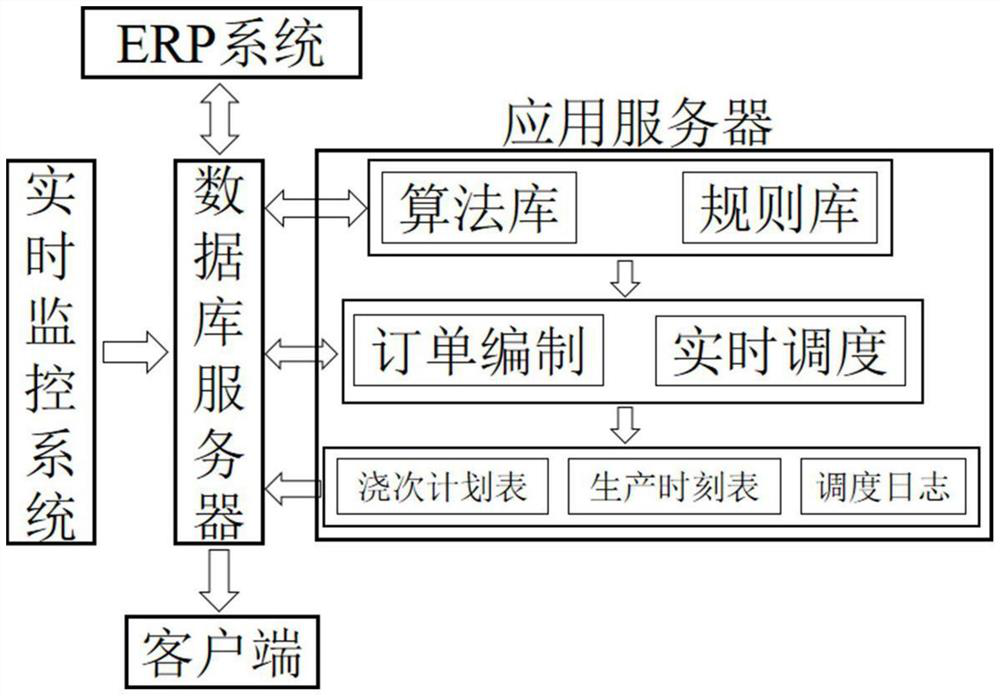

[0025] Embodiment 1: as figure 1 As shown, the present invention proposes a steelmaking production process intelligent scheduling system, which is characterized in that it includes an ERP system, a database server, a real-time monitoring system, a client, and an application server; the ERP system is connected to the database server by communication, and the The output end of the real-time monitoring system is communicatively connected to the input end of the database server, the output end of the database server is communicatively connected to the input end of the client, and the database server is communicatively connected to the application server.

[0026] Optionally, the database server runs a professional database management system to receive the production order information and steel process requirements parameters of the ERP system, the real-time monitoring data of the production site of the real-time monitoring system, and the processing of the application server. The ...

Embodiment 2

[0032] Embodiment 2: the present invention also proposes a kind of intelligent scheduling method of steelmaking production process, it is characterized in that, comprises the following steps:

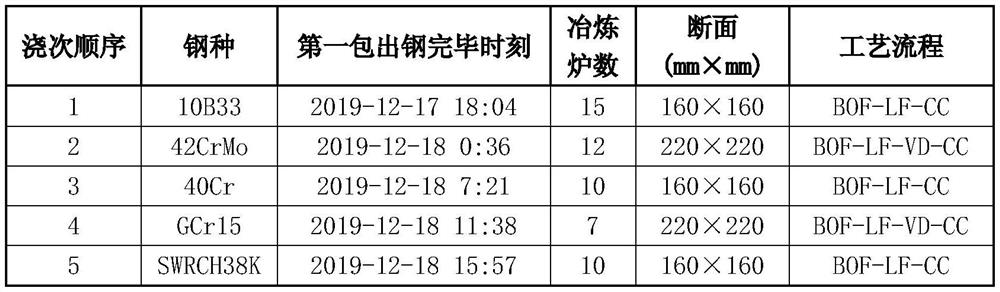

[0033] Step SS1: Order preparation, specifically including: obtaining production order information, according to the steel type, section, tonnage, equipment capacity and production process, following the principle of quality priority and stable full-load production to plan pouring times and specific furnaces for each pouring time The preparation of the production time of the second time is shown in Table 1;

[0034] Table 1 pouring schedule

[0035]

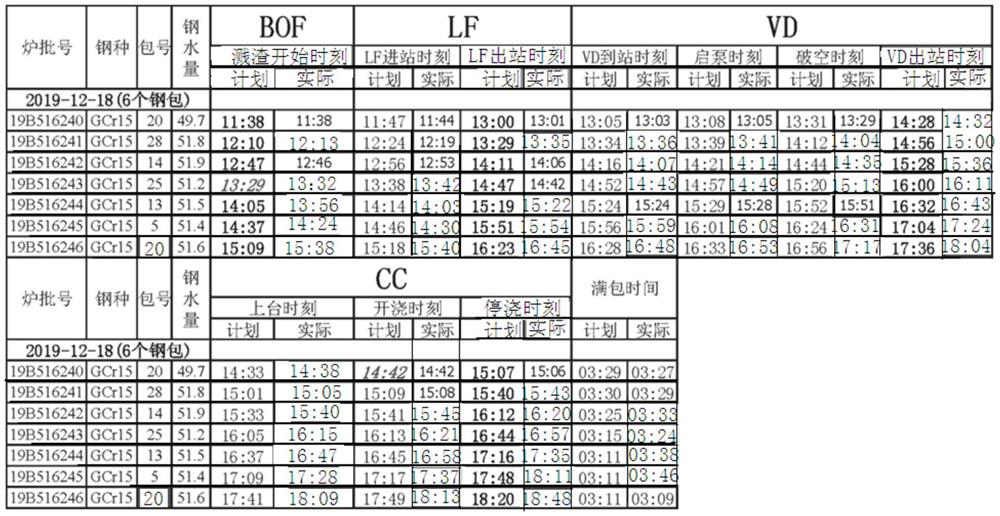

[0036] Step SS2: dynamic monitoring, which specifically includes: using the real-time monitoring system to collect the material flow, temperature, time and relevant abnormal working conditions of each process on the production site, and compare them with the production schedule of each pouring time. and displayed in tables or graphs, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com