Water quality filtration and separation equipment for oil field

A technology of water quality filtration and separation equipment, applied in the field of water filtration devices, can solve the problems of formation gap blockage, lower permeability, lower transportation capacity, lower crude oil production, etc., and achieve the effect of simple operation and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

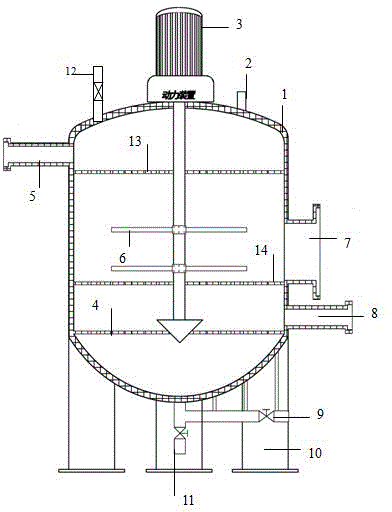

[0017] figure 1 As shown in , the oilfield water quality filtration and separation equipment consists of tank body 1, water inlet 5, water outlet 8, bottom sewage pipe 11, filter packing inlet and outlet 7, agitator 3, equipment bracket 10, backwash water inlet 9, pressure gauge interface 2 components; wherein, the inside of the tank body 1 is cavity-shaped, and the cavity of the tank body 1 is composed of a filter baffle 13 with a long hole, a filter baffle 14 with a circular hole and a filter baffle with a grid shape 4. Divide the tank into 4 spaces; the tank can be filled with filter filler through the inlet and outlet 7 of the filter filler to improve the sewage filtering effect. After water enters from the water inlet 5, the water will go down through the filter baffle 13 with long holes, the filter packing and the filter baffle 14 with ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com