Touch panel and repairing method thereof

a technology which is applied in the field of touch display panel and repairing method thereof, can solve the problems of low yield rate, often damaged touch control circuit, and inevitably thickening of additive-type touch display panel, and achieve the effect of favorable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

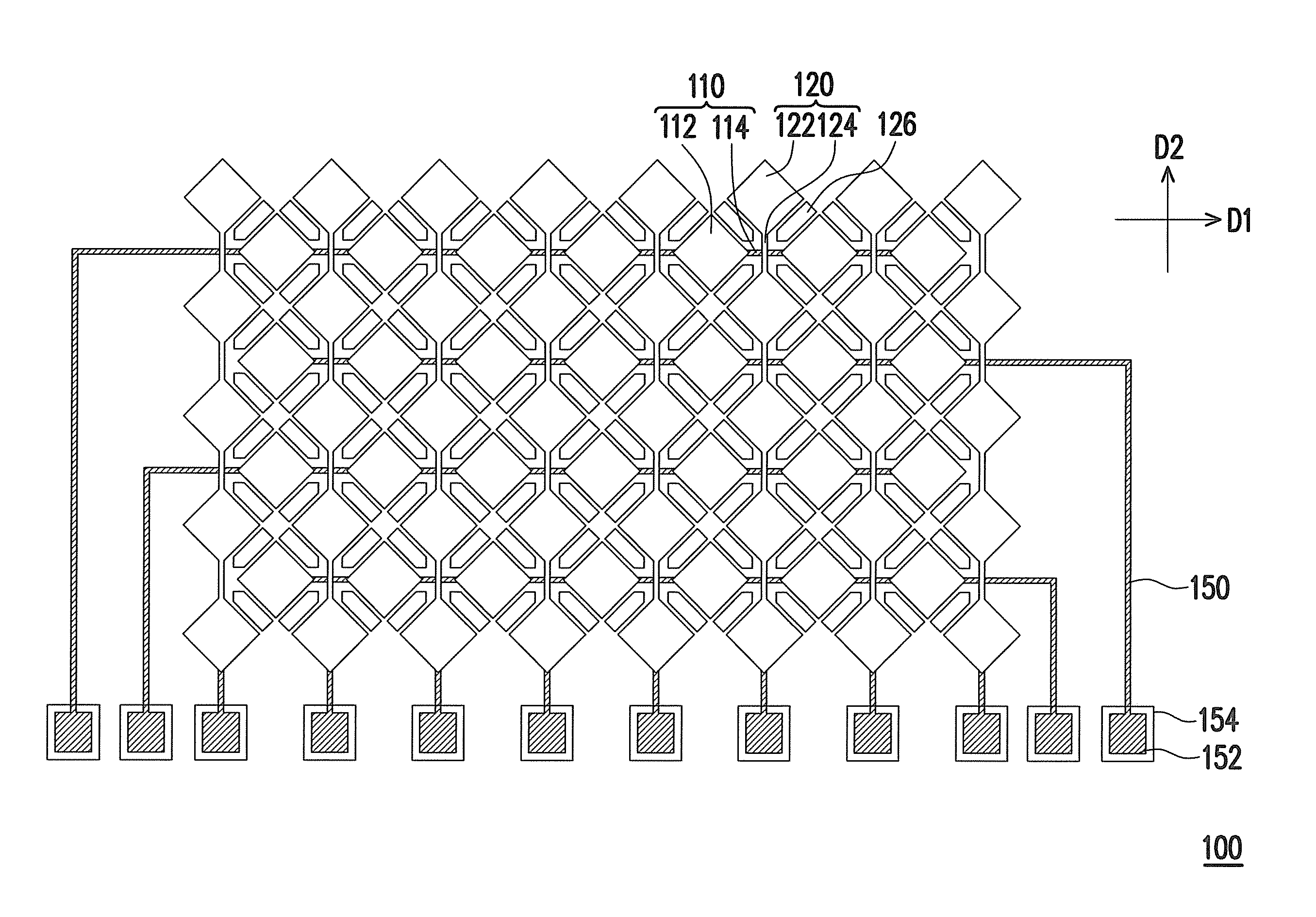

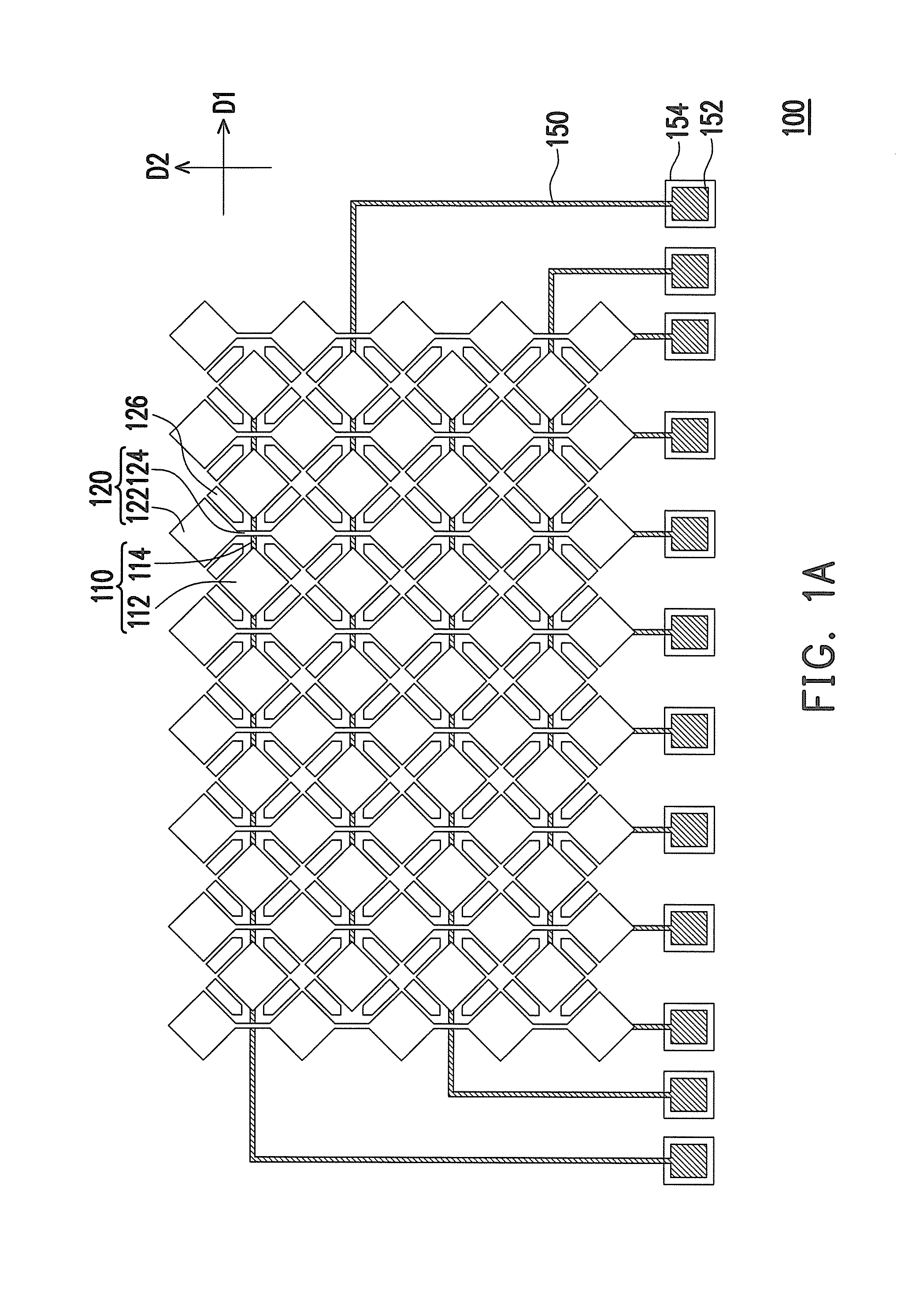

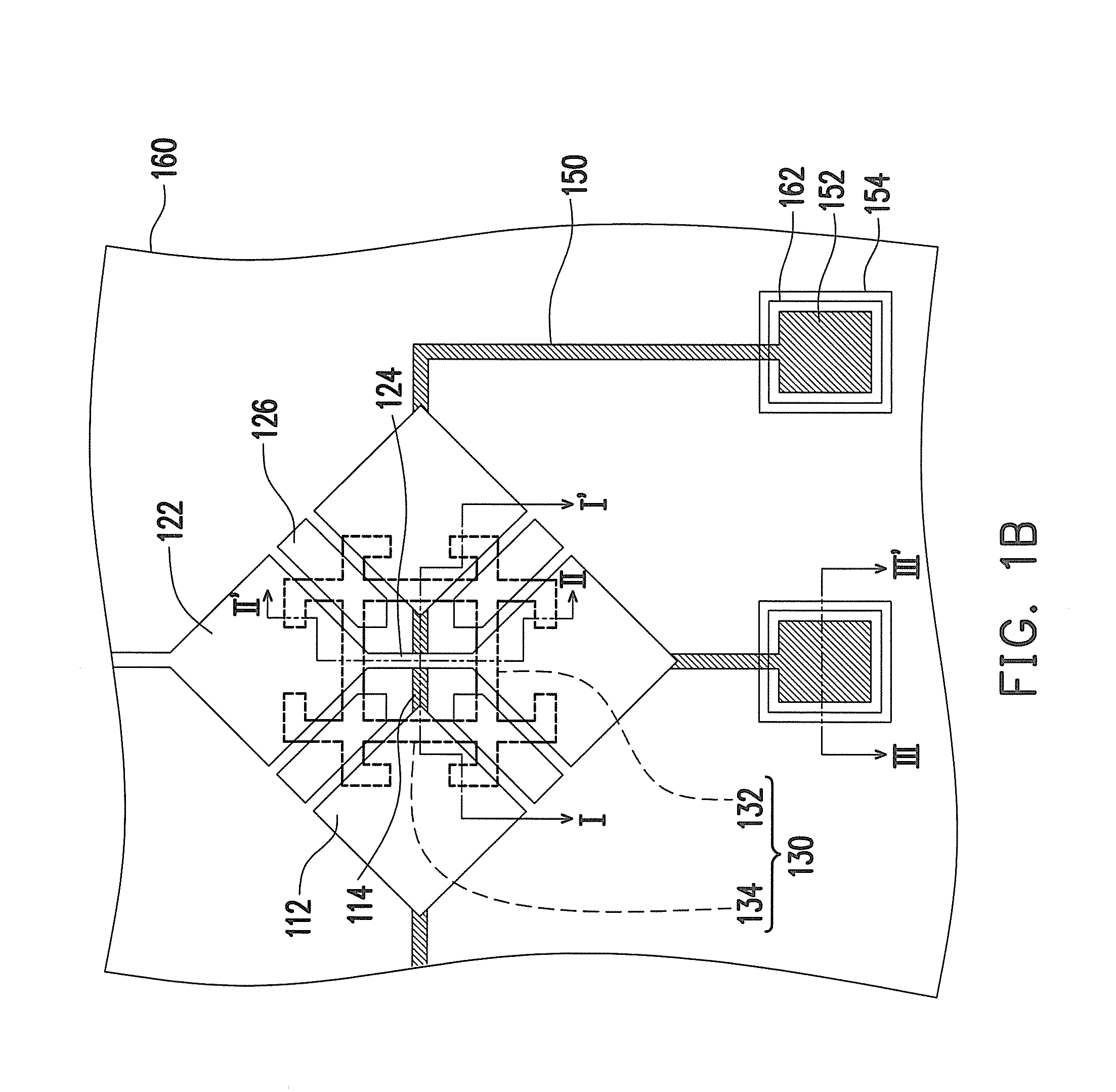

[0051]FIG. 1A is a schematic top view of a touch panel according to a first embodiment of the invention. FIG. 1B is a partially enlarged schematic diagram of FIG. 1A. FIG. 1C is schematic cross-sectional views taken along a line I-I′, a line II-II′, and a line III-III′ in FIG. 1B. Referring to FIG. 1A to FIG. 1C, in the embodiment, the touch panel 100 includes a substrate 102, a plurality of first sensing series 110, a plurality of the second sensing series 120, a plurality of conductive repairing pattern layers 130, and a first dielectric layer 140. The substrate 102 is, for example, a glass substrate, a plastic substrate, a flexible substrate, or other substrates. The substrate 102 can also be a printed circuit board or a display panel, such as a liquid crystal display panel, an organic display panel, an electrophoresis display panel, a plasma display panel, or other type display panels, and can directly assembly on the display panel or in the display panel. Ta...

second embodiment

The Second Embodiment

[0070]FIG. 6A is a schematic top view of a touch panel according to a second embodiment of the invention. FIG. 6B is a partially enlarged schematic diagram of FIG. 6A. FIG. 6C is schematic cross-sectional views taken along a line I-I′, a line II-II′, and a line III-III′ in FIG. 6B. Please simultaneously refer to FIG. 6A to FIG. 6C. In the embodiment, the touch panel 100 includes a substrate 102, a plurality of first sensing series 110, a plurality of the second sensing series 120, a plurality of conductive repairing pattern layers 130, a first dielectric layer 140, a second dielectric layer 160, a plurality of peripheral connecting lines 150, and a plurality of peripheral connecting pads 152. In the embodiment, the first dielectric layer 140 is, for example, disposed on the substrate 102, and includes a plurality of contact windows 142.

[0071]In the embodiment, the first sensing series 110 are disposed on the substrate 102 and extended along a first direction D1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductive | aaaaa | aaaaa |

| transparent conductive | aaaaa | aaaaa |

| metallic conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com