Repairing method for leakage of installation screw hole on installation surface of integration box

A repair method and installation surface technology, applied in the field of mechanical parts repair technology, can solve the problems of installation screw hole leakage and economic loss, and achieve the effects of avoiding scrap, prolonging service life and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A method for repairing leakage of mounting screw holes on the mounting surface of an integrated box is characterized by comprising the following steps:

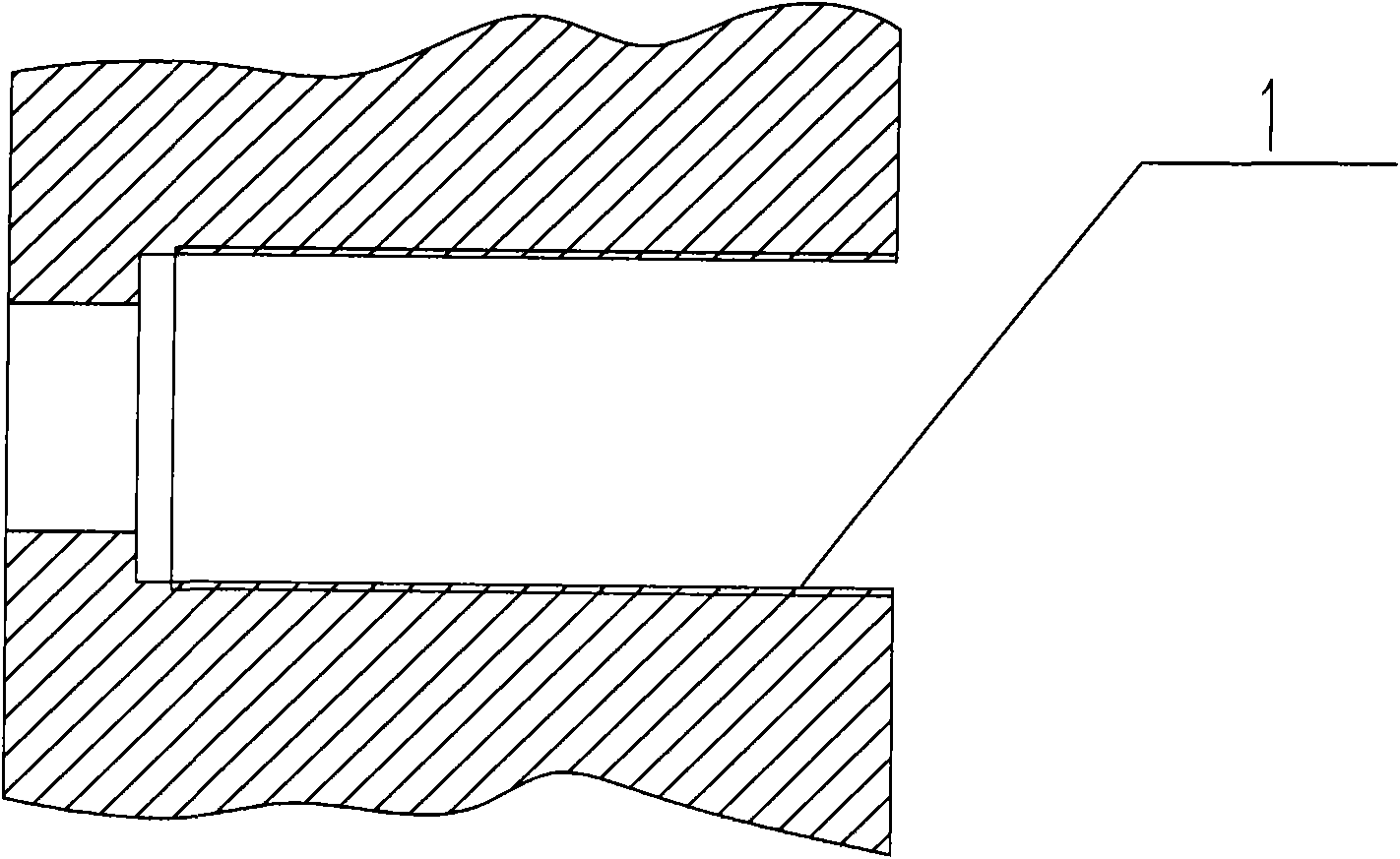

[0031] a. Ream the installation screw hole with leakage problem into a threaded hole 1 of M24×1.5, bottom hole ¢22.5mm, the thread adopts fine thread, the depth exceeds the leakage point by more than 5mm, and the bottom is spot-faced;

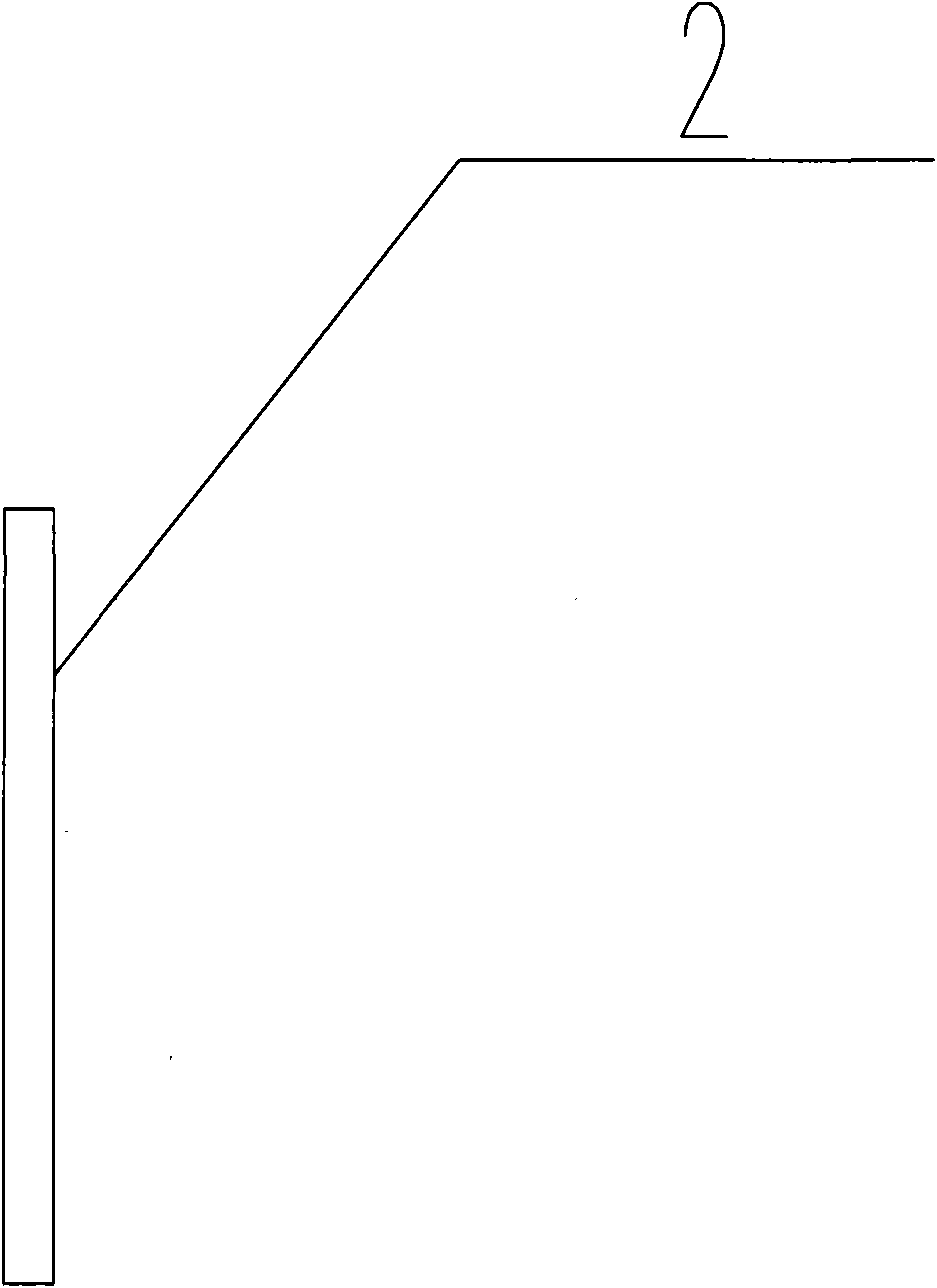

[0032] b. The copper gasket 2 with a thickness of 1.5mm and ¢22.5mm, with sharp edges and blunt edges, was burned red with oxyacetylene to make it annealed and softened;

[0033] c. Clean the inside of the threaded hole 1, trim the copper gasket 2 and place it at the bottom of the threaded hole 1;

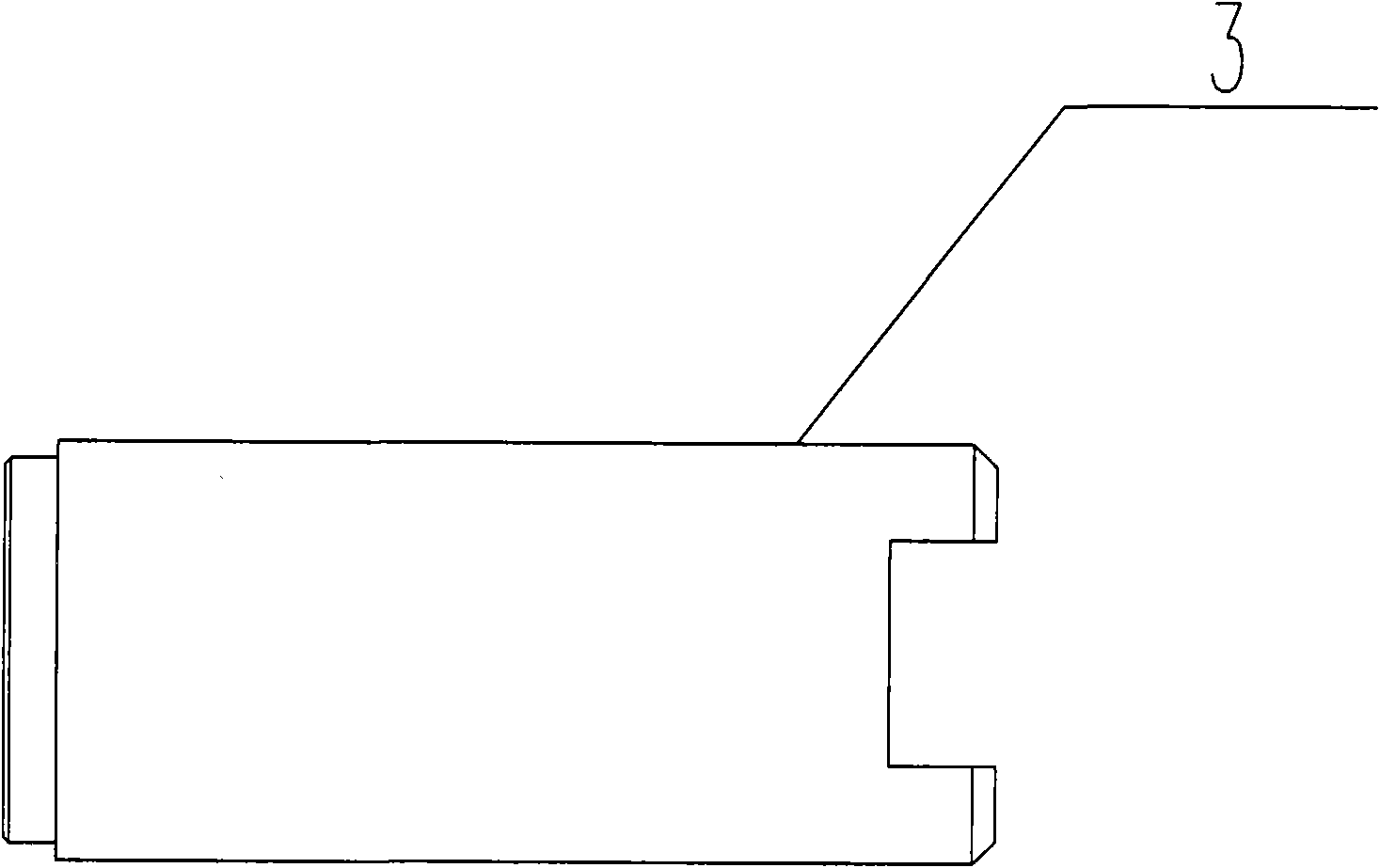

[0034] d. Turned M24×1.5 threaded sleeve 3, the length of which exceeds the depth of threaded hole 1 by 10mm;

[0035] e. Apply thread locking agent evenly on the surface of the screw sleeve 3, screw it into the threaded hole 1, and tighten it until the copper gasket 2 is completely pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com