In situ biofabrication method in vivo and its application in tissue repair in vivo

A bio-manufacturing, in-situ technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problems of detachment of fetal membranes, biocompatibility to be further verified, and poor tissue adhesion, so as to solve repair problems and improve adhesion. and fusion, the effect of promoting tissue repair and regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

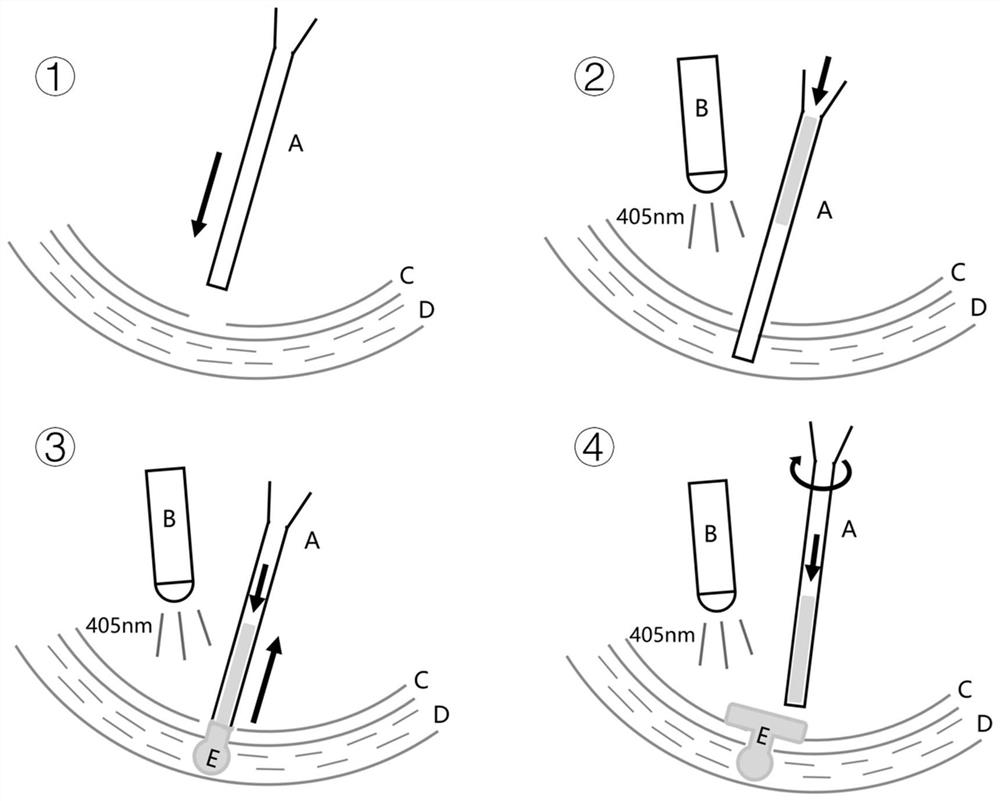

Method used

Image

Examples

Embodiment 1

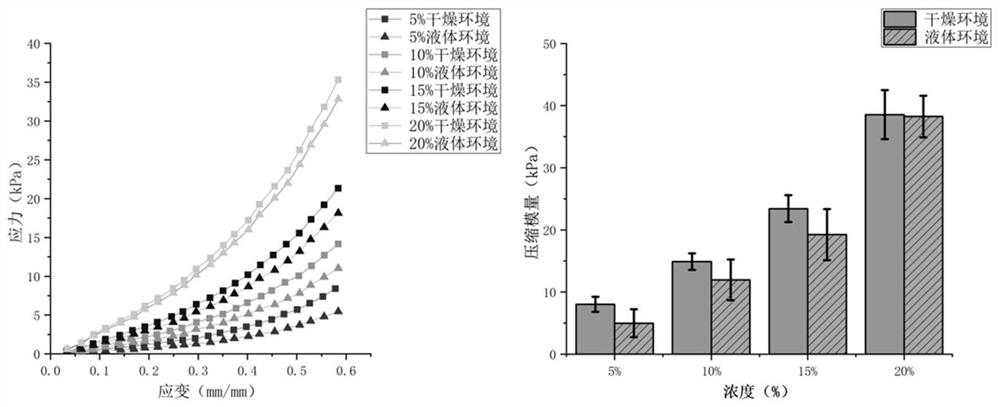

[0080] Example 1 The difference of GelMA concentration in the photosensitive restorative material is formed in a dry environment and a compressive modulus test in a liquid environment

[0081] In the photosensitive repair material prepared by the present invention, the final concentration of methacrylated gelatin GelMA in the photosensitive repair material is 5%-20% (w / v), and the final concentration of polyacrylate in the photosensitive repair material is 5%. -30% (w / v), the final concentration of the photoinitiator in the photosensitive repair material is 0.5%-1% (w / v), and the solvent of the photosensitive repair material is PBS phosphate buffer solution. The inventor found experimentally that the blue light initiator LAP only has an absorption value for light with a wavelength less than 405nm, see Figure 9 , so in the experiments, blue light with a wavelength of 405nm was used for irradiation.

[0082] 1. Configure different concentrations of photosensitive repair materi...

Embodiment 2

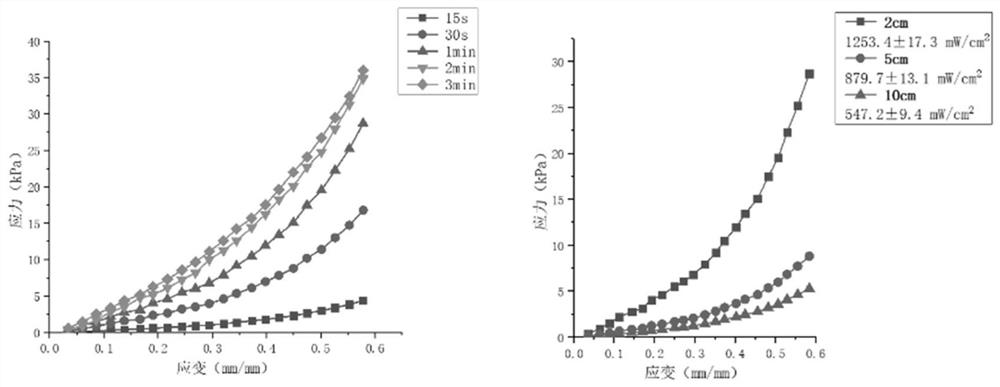

[0099] Example 2 Compression modulus test of the above-mentioned optimal concentration parameters of the photosensitive restoration material prepolymer formed in a liquid environment under different illumination times and different illumination intensities

[0100] 1. Refer to the method of Example 1 to configure the photosensitive restoration material prepolymer whose concentration is the above-mentioned optimal concentration parameter. In the photosensitive repair material, the final concentration of methacrylated gelatin GelMA in the photosensitive repair material is 16% (w / v), and the final concentration of polyacrylate in the photosensitive repair material is 10% (w / v). The final concentration of the agent in the photosensitive repair material is 0.8% (w / v).

[0101] With reference to the method of Example 1, inject this solution into the standard sample mold soaked in Ringer's solution, and immediately irradiate the photosensitive repair material with blue light of 405nm...

Embodiment 3

[0108] Example 3 Effects of Different Polyacrylate Concentrations in Photosensitive Restoration Materials on Tissue Adhesion

[0109] 1. With reference to the photosensitive restoration material formula of Example 1, prepare the photosensitive restoration material prepolymer with polyacrylate concentration gradient, in 4 concentration gradients, the concentration of GelMA is 16% (w / v), LAP photoinitiator The concentration is 0.8% (w / v), the concentration of polyacrylate is 10%, 15% and 20% and 30% respectively, polyacrylate is not added in the control group, other components are consistent with the experimental group, the solvent is PBS phosphate buffer solution.

[0110] 2. Measurement of adhesion characteristic parameters

[0111] Select a glass slide modified with primary amino groups on the surface to simulate the surface of human tissue rich in primary amino groups, drop different concentrations of photosensitive repair materials on the glass slide, and cover one end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com