Two-stage unsupported construction method used for repairing damaged hydraulic concrete beams

A hydraulic concrete and disease technology, applied in water conservancy engineering, construction, marine engineering and other directions, can solve the problems of inability to carry out maintenance, difficult to implement, and unable to bear weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

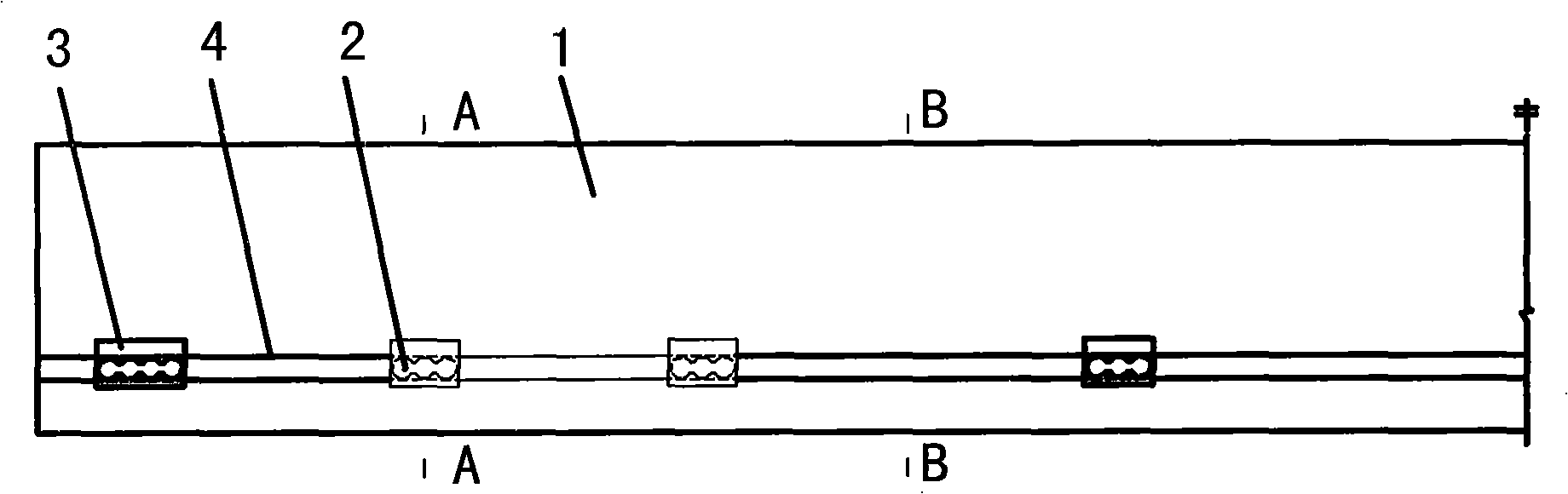

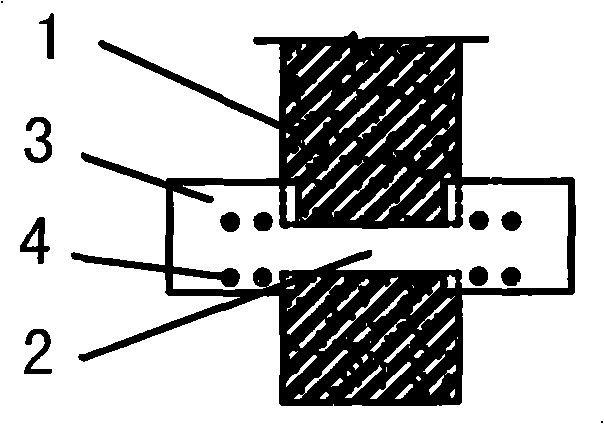

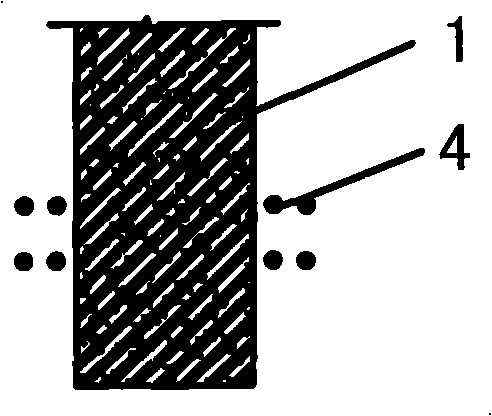

[0023] This embodiment takes the repair of the longitudinal girder of an approach bridge located at a seaport wharf along the coast of a certain place as an example. The approach bridge has a length of 147m and a width of 7m, and adopts a pile-based beam-slab structure. The whole bridge consists of 12 bent frames and 11 spans, of which 10 spans use concrete simply supported longitudinal girders. Each bridge spans 3, a total of 30 simply supported beams, with a beam span of 14m. As an approach bridge for an oil terminal, dozens of oil pipelines and other pipelines are arranged on the bridge. After on-site exploration and inspection, the main reinforcement at the bottom of 30 beams was completely corroded, the concrete protective layer burst, and the corrosion loss rate of the steel bar section reached about 25%, which seriously threatened the safety of the project and must be repaired immediately.

[0024] During the discussion of the scheme, some schemes were analyzed and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com