Marine-derived bionic cartilage material and preparation method thereof

A bionic and cartilage technology, applied in the medical field, can solve problems such as poor functionality, high biological risk, and high risk, and achieve the effects of low risk of carrying and spreading, low risk of virus transmission, and wide-ranging sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

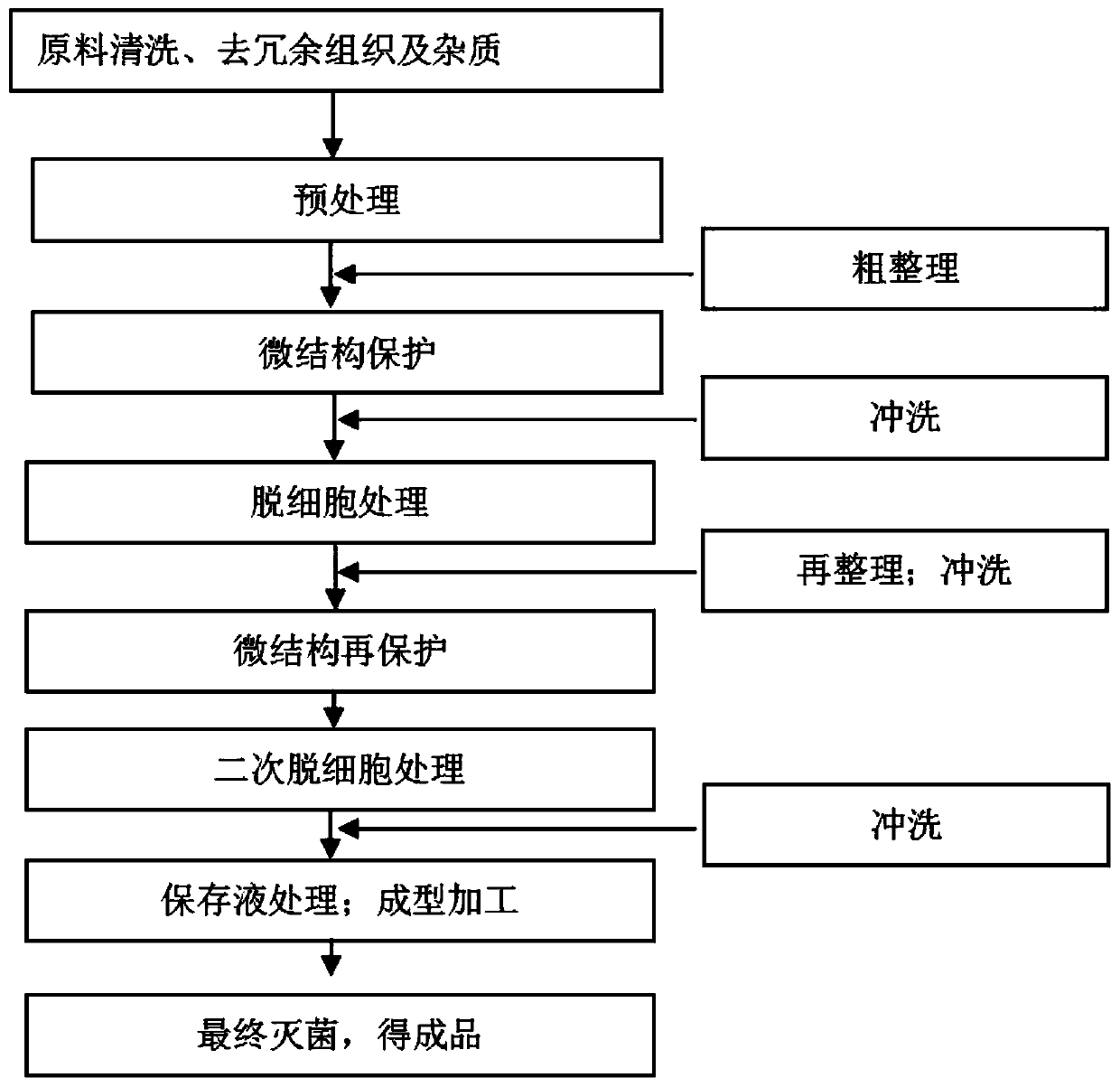

[0036] refer to figure 1 As shown, the present invention provides a method for preparing marine-derived biomimetic cartilage material, comprising the steps of:

[0037] (1) Raw material pretreatment: Remove redundant tissues and impurities from the marine-derived cartilage material, cut it into a suitable size, and freeze it at a low temperature for later use;

[0038] (2) Pretreatment: at 4°C, stir the cartilage material treated in step (1) with a 2%-5% NaCl solution with a solid-liquid ratio of 1:5-1:20 (w / w) for 1-4 hours and then remove For waste liquid, repeat 2-4 times; then perform rough finishing to remove residual redundancy;

[0039] (3) Microstructure protection: at 4°C, stir the pretreated cartilage material in step (2) with a phosphate buffer solution with a solid-to-liquid ratio of 1:5-1:20 (w / w) for 2-4 hours, and then remove the waste solution; the above steps were repeated 1-3 times;

[0040] (4) Cleaning: at 4°C, stir the cartilage material treated in step...

Embodiment 1

[0056] (1) Raw material pretreatment: remove redundant and other tissues from the fresh anglerfish cartilage, rinse it with deionized water at 4°C for several times; then cut it into appropriate sizes according to different anatomical parts, with a thickness of about 0.3cm; then quickly place it at -40 ℃ frozen, take out and thaw under running water at room temperature before use.

[0057] (2) Pretreatment: at 4°C, stir the cartilage material treated in step (1) with a 5% NaCl solution with a solid-to-liquid ratio of 1:20 (w / w) for 3 hours, then remove the waste liquid, and repeat twice; Roughly organize and remove some residual redundancy.

[0058] (3) Microstructure protection: Stir the pretreated cartilage material in step (2) with phosphate buffer (0.2M, pH7.2) at a solid-to-liquid ratio of 1:20 (w / w) for 2 hours at 4°C Remove the waste liquid; repeat the above steps 2 times.

[0059] (4) Cleaning: at 4°C, the cartilage material treated in step (3) was stirred with deion...

Embodiment 2

[0067] (1) Raw material pretreatment: remove redundant and other tissues from the fresh anglerfish cartilage, rinse it with deionized water at 4°C for several times; then cut it into appropriate sizes according to different anatomical parts, with a thickness of about 0.3cm; then quickly place it at -40 ℃ frozen, take out and thaw under running water at room temperature before use.

[0068] (2) Pretreatment: at 4°C, stir the cartilage material treated in step (1) with a 6% NaCl solution with a solid-to-liquid ratio of 1:20 (w / w) for 3 hours, then remove the waste liquid, and repeat twice; Roughly organize and remove some residual redundancy.

[0069] (3) Microstructure protection: Stir the pretreated cartilage material in step (2) with phosphate buffer (0.2M, pH7.2) at a solid-to-liquid ratio of 1:20 (w / w) for 2 hours at 4°C Remove the waste liquid; repeat the above steps 2 times.

[0070] (4) Cleaning: at 4°C, the cartilage material treated in step (3) was stirred with deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com