Shield tunnel pipe piece fracture blockage device and construction method

A shield tunnel segment and fissure sealing technology, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the security threats of shield tunnels in the later operation of subways, the aging of plugging materials, and the loss of plugging materials, etc. Achieve the effect of solving penetrating and non-penetrating crack plugging and repairing problems, reducing the risk of shedding, and preventing the risk of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

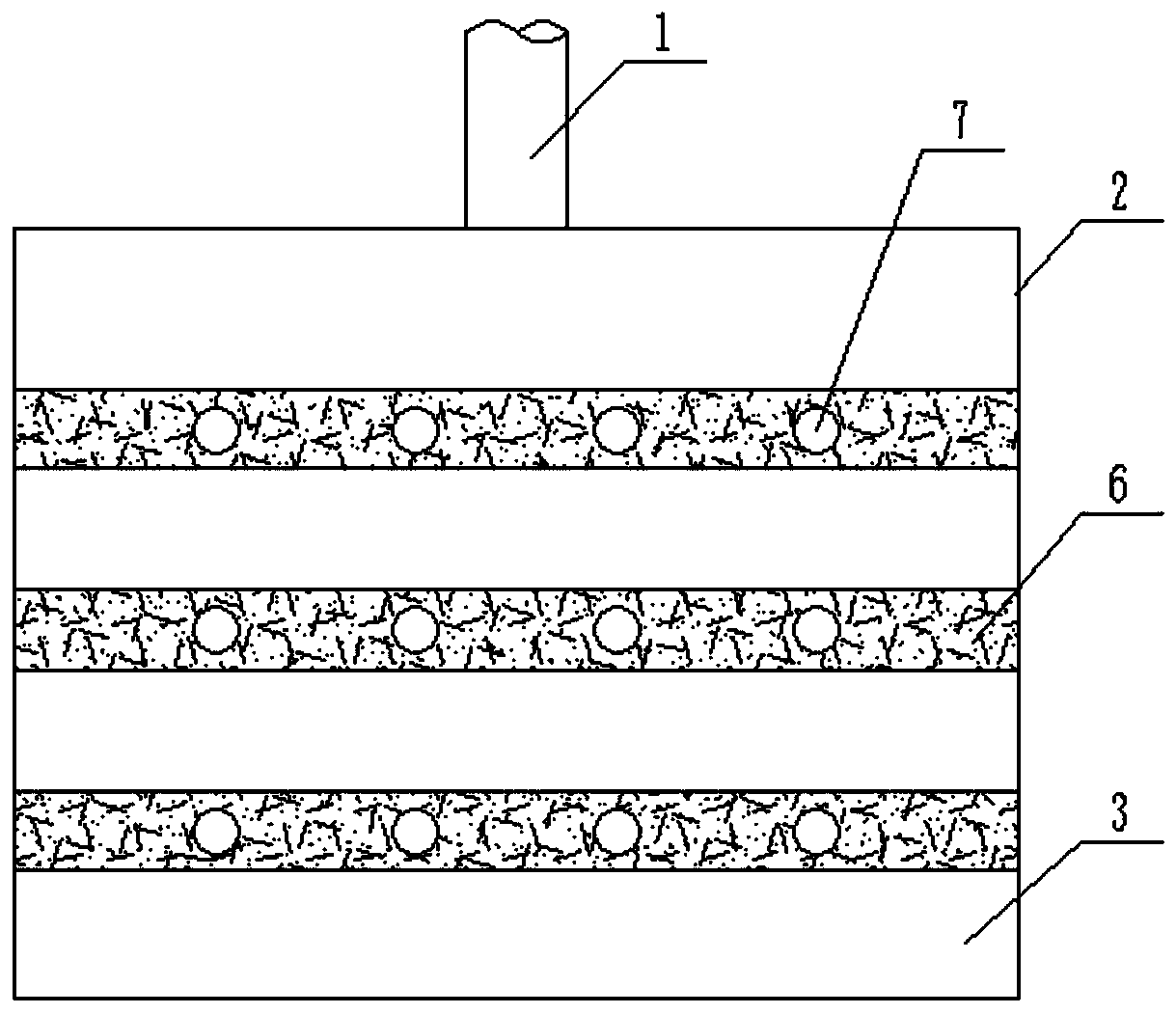

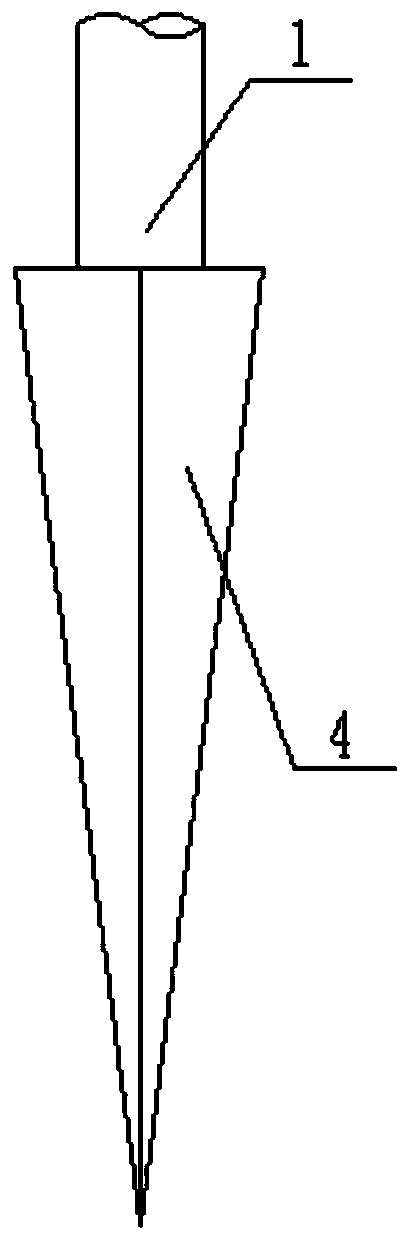

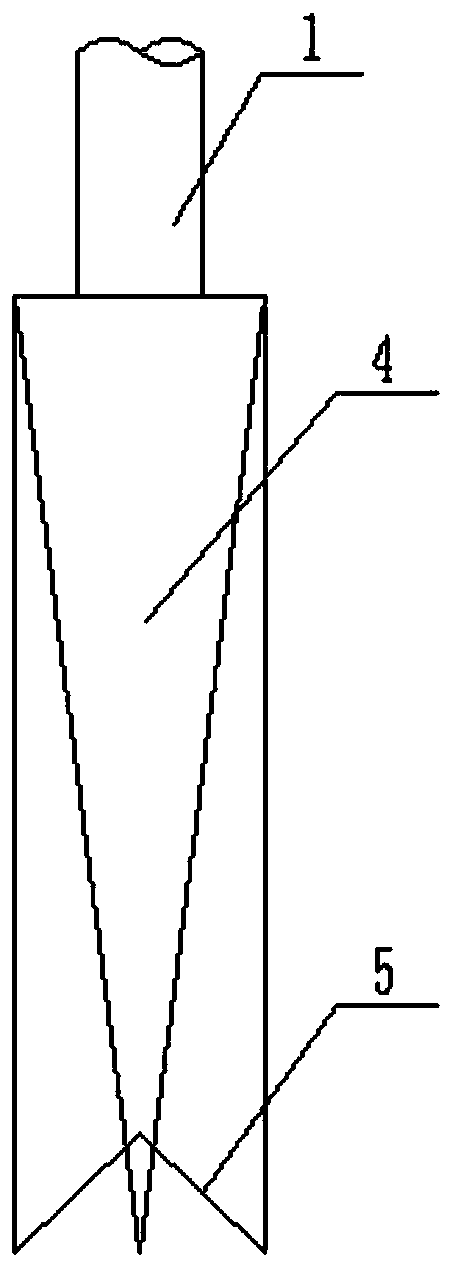

[0046] Such as Figures 1 to 5 As shown, the present invention provides a shield tunnel segment crack sealing device, comprising: an iron box 2, which includes a top plate, a pair of first side plates 3, a pair of second side plates 4 and a bottom plate 5, the top plate And a pair of first side plates 3 are square and a pair of first side plates 3 are relatively fixed on both sides of the top plate, a pair of second side plates 4 are V-shaped and relatively fixed on the other side of the top plate On both sides, the bottom plate 5 is welded by two square plates in an inverted V shape and fixed on the bottom edge of a pair of first side plates 3, and a pair of first side plates 3 are in a matrix and symmetrically provided with a plurality of reserved Grouting hole 7, the center of the top plate is provided with a grouting hole, and the iron box 2 is made of flexible steel sheet; the grouting pipe 1 is reserved, and its vertical seal is connected to the grouting hole; the rubber...

Embodiment 2

[0056] Such as Figures 6 to 8 As shown, on the basis of Example 1, in order to better realize grouting plugging, and after the construction is completed, the reserved grouting pipe 1 can be easily removed without using additional tools for cutting, the present invention also sets The structure of the reserved grouting pipe 1 is not welded and fixed with the iron box 2, but is vertically inserted into the grouting hole and close to the inner wall of the grouting hole, and the upper part of the reserved grouting pipe 1 is evenly spaced along its circumference A plurality of through holes are provided, and part of the material near the through holes of the reserved grouting pipe 1 is set as an elastic material 19. The lower part of the reserved grouting pipe 1 is also provided with a plurality of channels at even intervals along its circumference. A horizontal elastic member is arranged inside, the length of the elastic member in a free state is greater than the length of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com