Split washer mounting device with detection function

A technology for tapping devices and inlet holes, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low installation efficiency of opening retaining rings and low job skill requirements for operators, and achieve low post skill requirements and realize Continuity of action, solving the effect of low installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

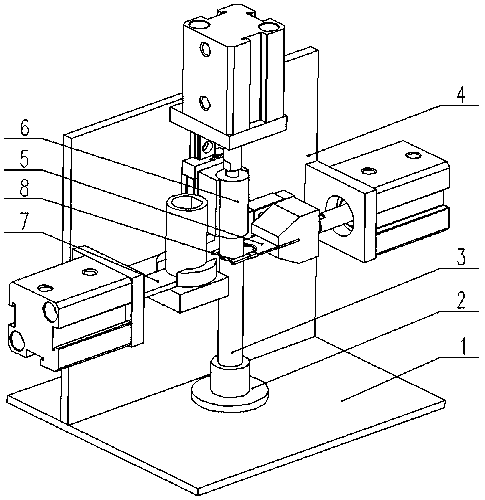

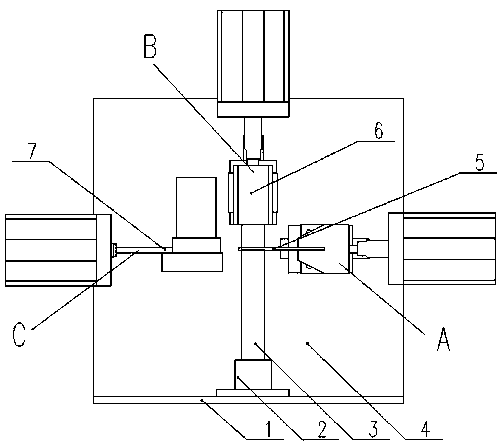

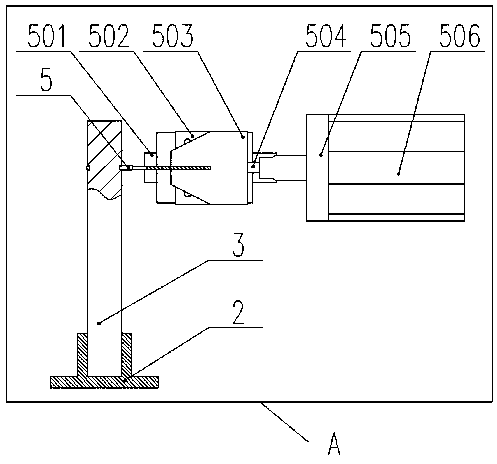

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 as well as Figure 8 As shown, an installation device for an open retaining ring with a detection function includes a base plate 1, a support seat 2, a rotating shaft 3, a spring groove 301, a side plate 4, a go-no-go gauge 5, a first guide rail 501, and a first slider 502 , clamping block 503, first cylinder connector 504, first cylinder fixing plate 505, first cylinder 506, hole clamping plate 507, shaft clamping plate 508, pressure head 6, second cylinder 601, second cylinder fixing Plate 602, second cylinder connector 603, second slider 604, second guide rail 605, push block 7, feeding barrel 701, pad 702, third cylinder fixing plate 703, third cylinder connector 704, third cylinder 705, the limit groove 706 and the opening retaining ring 8, the support base 2 is fixed on the base plate 1; the support base 2 is provided with a through hole, and the inside of the through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com