Method for maintaining heat-resisting cushion block of stepping type heating furnace

A technology of stepping heating furnace and pad, applied in the field of metallurgical heating furnace, can solve the problems of burning crack, long maintenance time, shortened service life, etc., and achieve the effect of increasing service life, reducing labor cost, and reducing cost of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

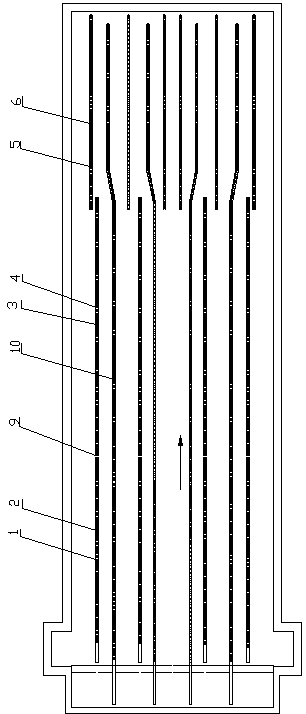

[0062] First, a brief description of the water-cooled beam heat-resistant pad of the walking heating furnace:

[0063] Such as figure 1 As shown, the structure of the water-cooled beam of the walking heating furnace is shown, including steel pipes, and the steel pipes are provided with pads, which are characterized in that: the pads include pad one 1, pad two 3, pad three 5, The pad one 1 is a cuboid as a whole, and the lower end is provided with a bevel at the contact part with the water-cooled beam. The pad one 1 is arranged on the water-cooled beam 2 of the preheating section of the walking heating furnace. The pad two 3, the pad Three 5 are respectively arranged on the water-cooled beam 4 of the heating section and the water-cooled beam 6 of the soaking section of the walking heating furnace. The upper part of the spacer 2 3 and the spacer 3 5 is a cuboid structure, and the lower part is a long strip saddle structure.

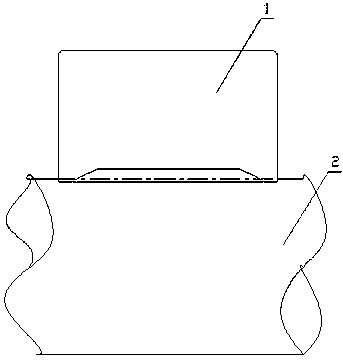

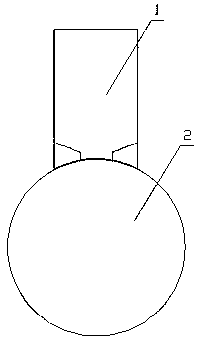

[0064] figure 2 , image 3 It shows the schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com