Acid washing cold rolling combined unit inlet loop filling speed control method

A combined unit, pickling cold rolling technology, applied in rolling mill control devices, metal rolling, tail end control, etc., can solve problems such as equipment impact, increase the accident rate in the inlet looper area, and affect the normal development of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

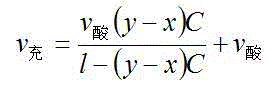

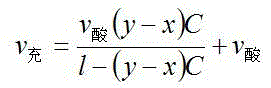

[0035] For strip steel of L11304771700, the weight is 26.617t, the material thickness is 2.998mm, and the material width is 1.202m, so the material length is l=946m, and x=25% at the beginning of filling, and the full set is y=95%, constant C=572, v-acid=250m / min, brought into the formula to get:

[0036] m / min

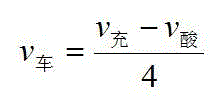

[0037] If the maximum speed and 700m / min speed are used to fill the sleeve, the speed of the trolley is m / min

[0038] The filling speed calculated by this formula is m / min

[0039] It is 40.75% of full-speed charging, and the impact on the equipment will be greatly reduced.

[0040] According to the maximum speed of filling, the tracking time of this one roll from filling to flicking to welding machine waiting for welding is: from the beginning of filling to the time of fully filling min, the time it takes from full to the tail swing to the welding machine min, total time min.

[0041] According to the filling speed calculated by this formula, the tot...

Embodiment 2

[0043] L11304771100, the weight is 25.715t, the material thickness is 3.798mm, and the material width is 1.225m, then the material length l=708m, set x=25% at the beginning of filling, set y=95% for the full set, constant C=572, V acid = 240m / min, brought into the formula to get:

[0044] m / min

[0045] If the maximum speed and 700m / min speed are used to fill the sleeve, the speed of the trolley is m / min

[0046] The speed of the trolley calculated by this formula is m / min

[0047] It is 67.9% of the full-speed charging, and the impact on the equipment is greatly reduced.

[0048] It can also be seen that the time from the start of filling to the tail swinging to the welding machine is the same.

Embodiment 3

[0050] L11304771100, the weight is 28.177t, the material thickness is 2.297mm, and the material width is 1.5088m, then the material length l=1042m, set x=25% at the beginning of filling, set the full set amount as y=95%, constant C=572 , v-acid=260m / min, brought into the formula to get:

[0051] m / min

[0052] If the maximum speed and 700 speed are used to fill the case, the speed of the car is m / min

[0053] The speed of the trolley calculated by this formula is m / min

[0054] It is 36.8% of full-speed charging, and the impact on the equipment is greatly reduced.

[0055] It can also be seen that the time from the start of filling to the tail swinging to the welding machine is the same.

[0056]The above examples show that the optimal filling speed is used to fill the sleeve, and the strip filling speed and the running speed of the looper are greatly reduced. Especially when rolling strip steel and high-strength steel with specifications below 3.0, the speed of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com