Intelligent-type pneumatic actuating mechanism with fault diagnosis function

A pneumatic actuator and fault diagnosis technology, applied in the direction of engine components, mechanical equipment, valve details, etc., can solve the problems of difficulty in preparing spare parts, large number of valves, and poor pertinence, so as to ensure maintenance progress and quality, Spare parts are timely and accurate to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment the present invention is further described.

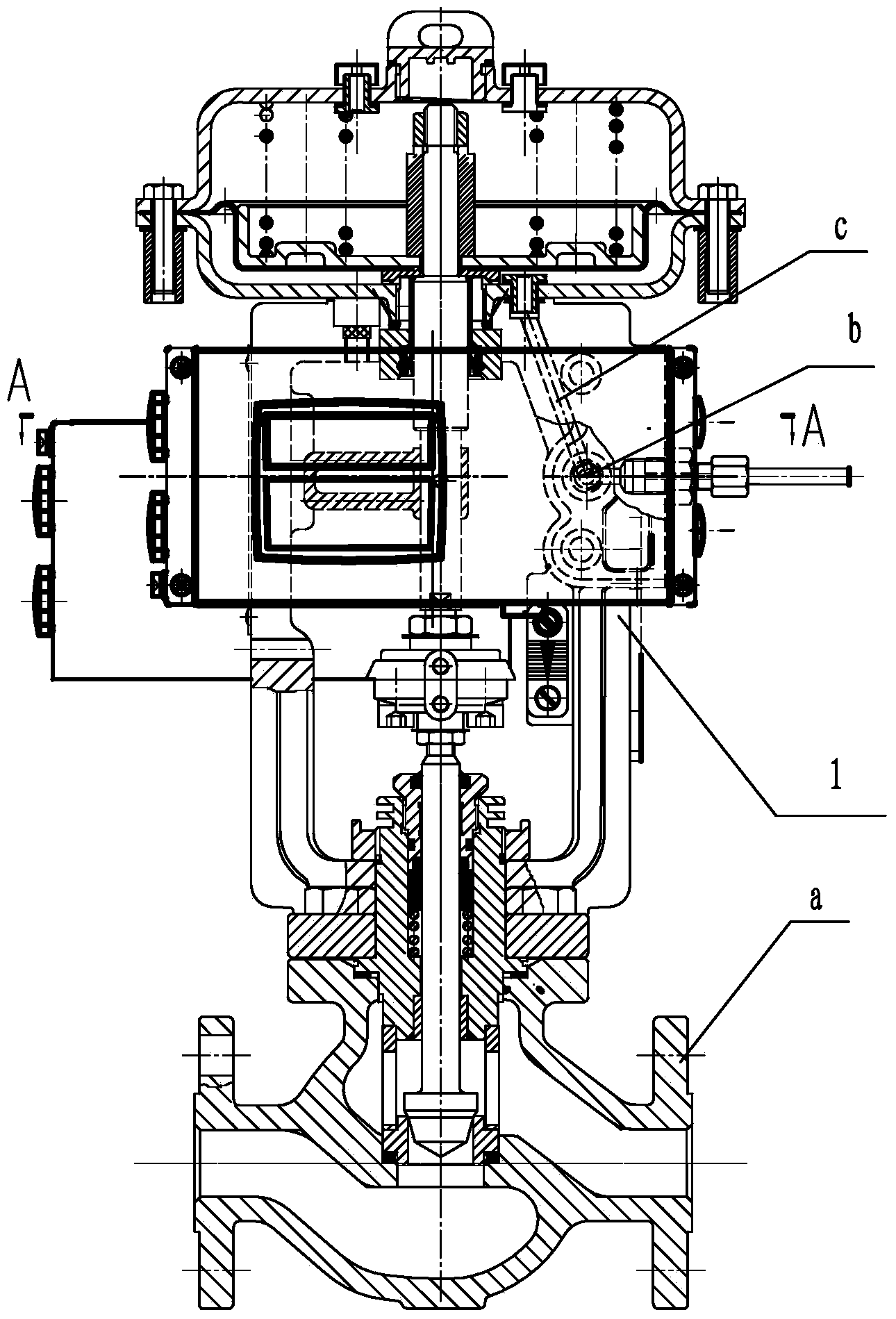

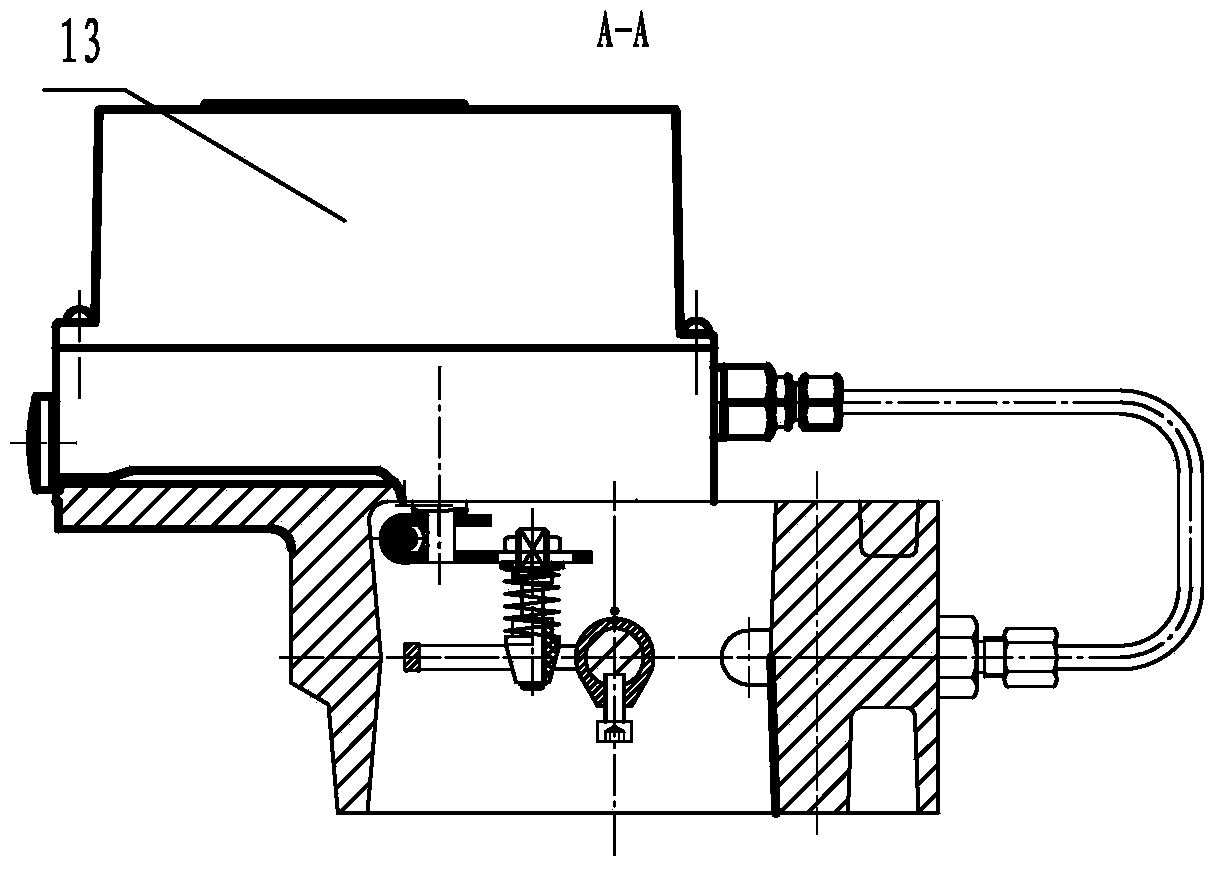

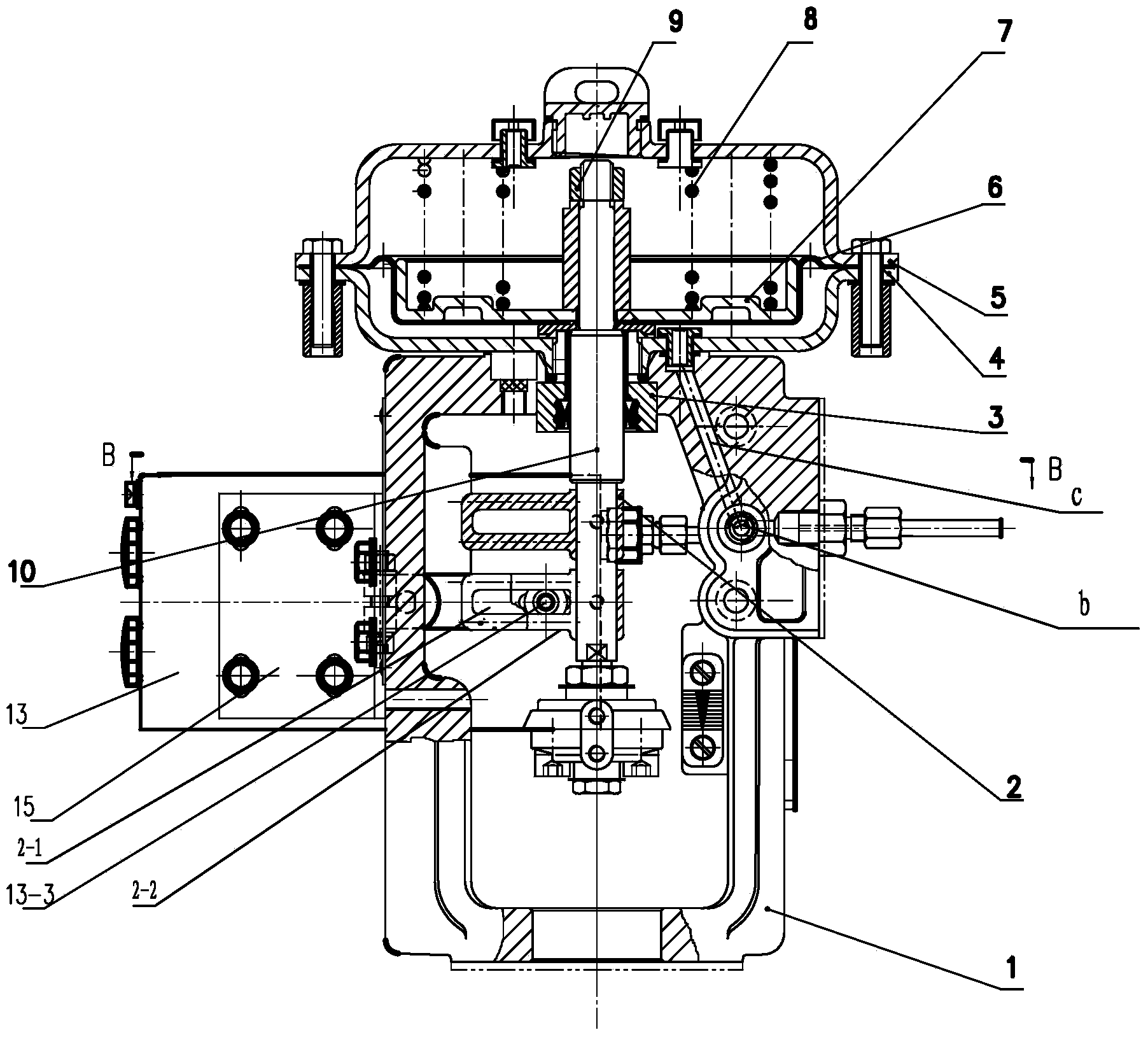

[0040] As shown in the accompanying drawings, an intelligent pneumatic actuator with fault diagnosis includes a bracket 1 connected to the regulating valve a, and a push rod 10 connected to the valve core is movably installed in the bracket 1. Above the bracket 1, there is The pressure membrane chamber, the pressure membrane chamber is mainly composed of the upper membrane cover 5 and the lower membrane cover 4. There is a diaphragm 6 between the upper membrane cover and the lower membrane cover, and the diaphragm 6 divides the pressure membrane chamber into an upper membrane chamber and the lower membrane chamber, above the diaphragm there is a tray 7 close to the diaphragm, a plurality of springs 8 are installed between the upper part of the tray 7 and the lower part of the upper membrane cover 5, and the push rod 10 The upper part of the upper part extends into the pressure membrane ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com