Steel wire high-pressure water flushing method and device thereof

A flushing device and high-pressure water technology, which is applied in the field of metal product processing, can solve problems such as low water pressure in the system, increased faults, and damage to the bottom valve, so as to ensure the cleaning quality and reduce the frequency of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

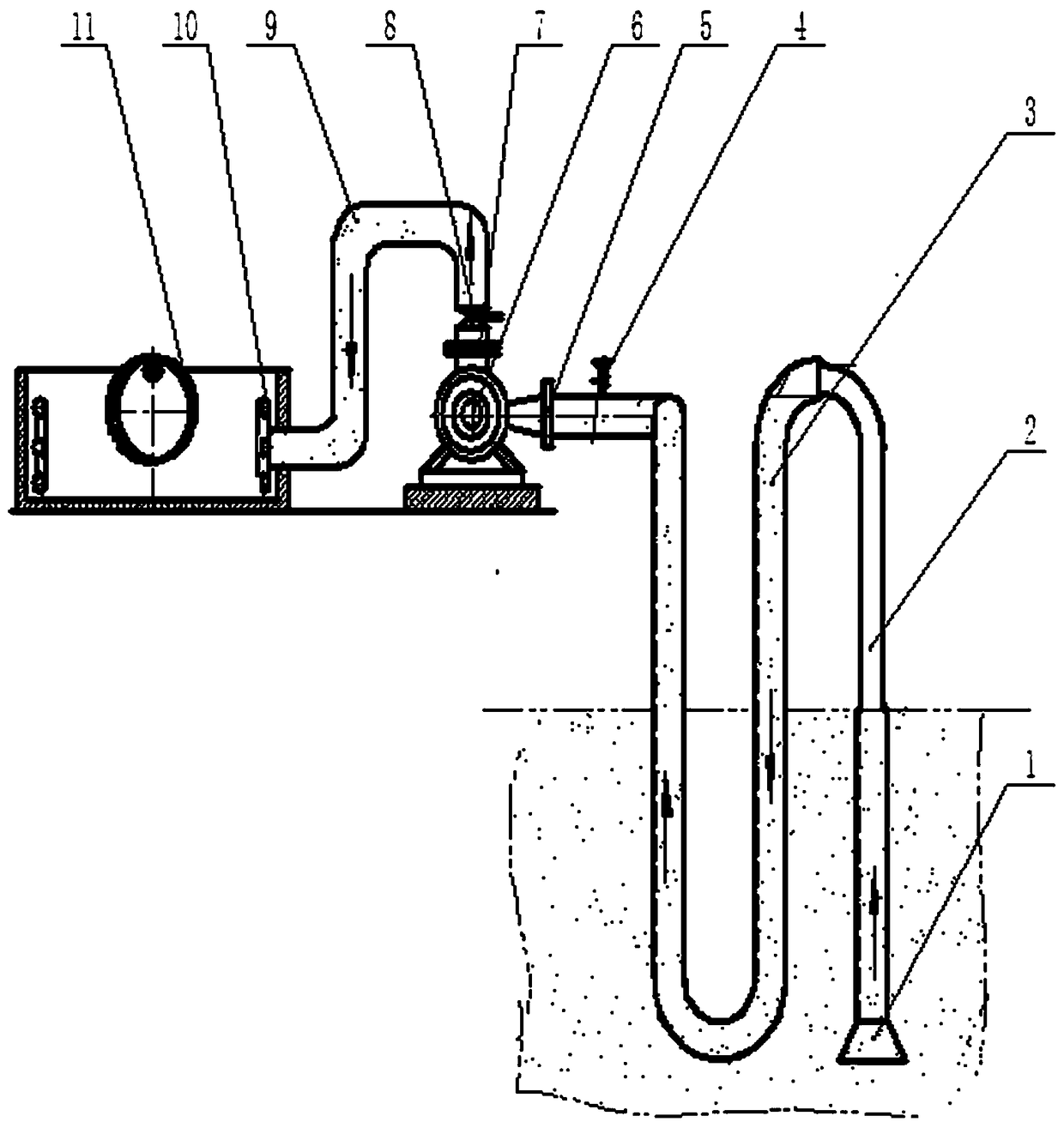

[0011] A steel wire high-pressure water flushing device of the present invention, the specific implementation method is as follows: figure 1 , it is mainly composed of DN150 horn-shaped steel pipe 1, DN110 intermediate connecting steel pipe 2, DN150 U steel pipe 3, DN15 ball valve 4, connecting flange Ⅰ 5, multi-stage horizontal centrifugal pump 6, connecting flange Ⅱ 7, DN150 check valve 8, DN150 Conveying pipeline 9 and water spray pipe group 10; DN150 trumpet-shaped steel pipe 1 and DN150U-shaped steel pipe 3 are connected through DN110 intermediate connecting steel pipe 2, and the water inlet end of multi-stage horizontal centrifugal pump 6 is connected with connecting flange Ⅰ5, which is sequentially connected with DN15 ball valve 4 is connected, and the water inlet and outlet of multistage horizontal centrifugal pump 6 are connected with connecting flange II 7, which are connected with DN150 check valve 8, DN150 delivery pipeline 9 and water spray pipe group 10 in turn. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com