Combined antiwearing blades

A combined, impeller technology, applied in non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve problems such as high cost and difficult impellers, and achieve high production efficiency and cost. The effect of increasing less and reducing the frequency of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

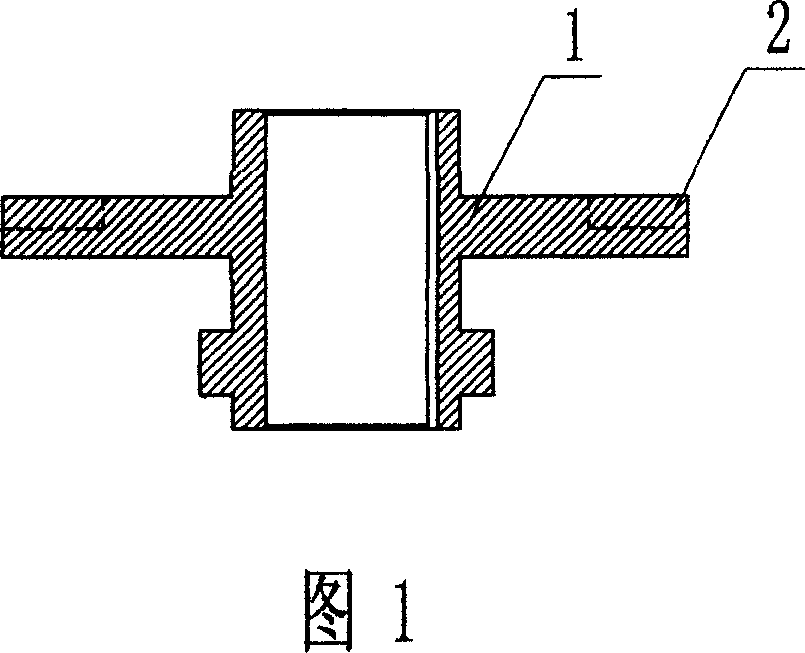

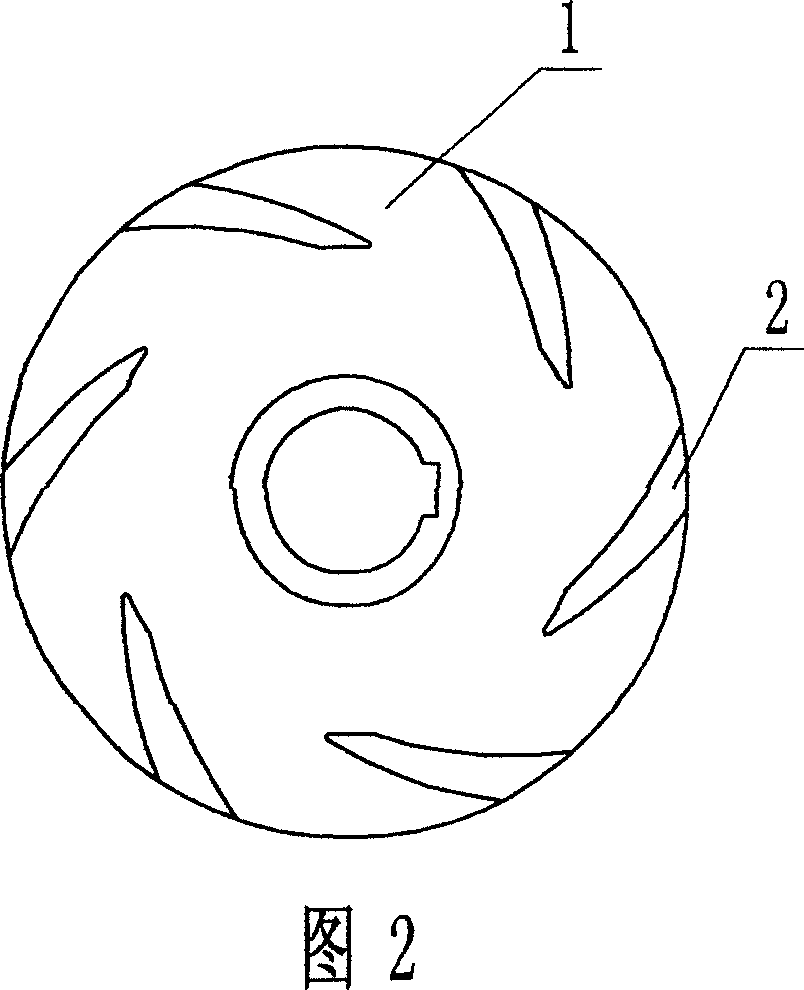

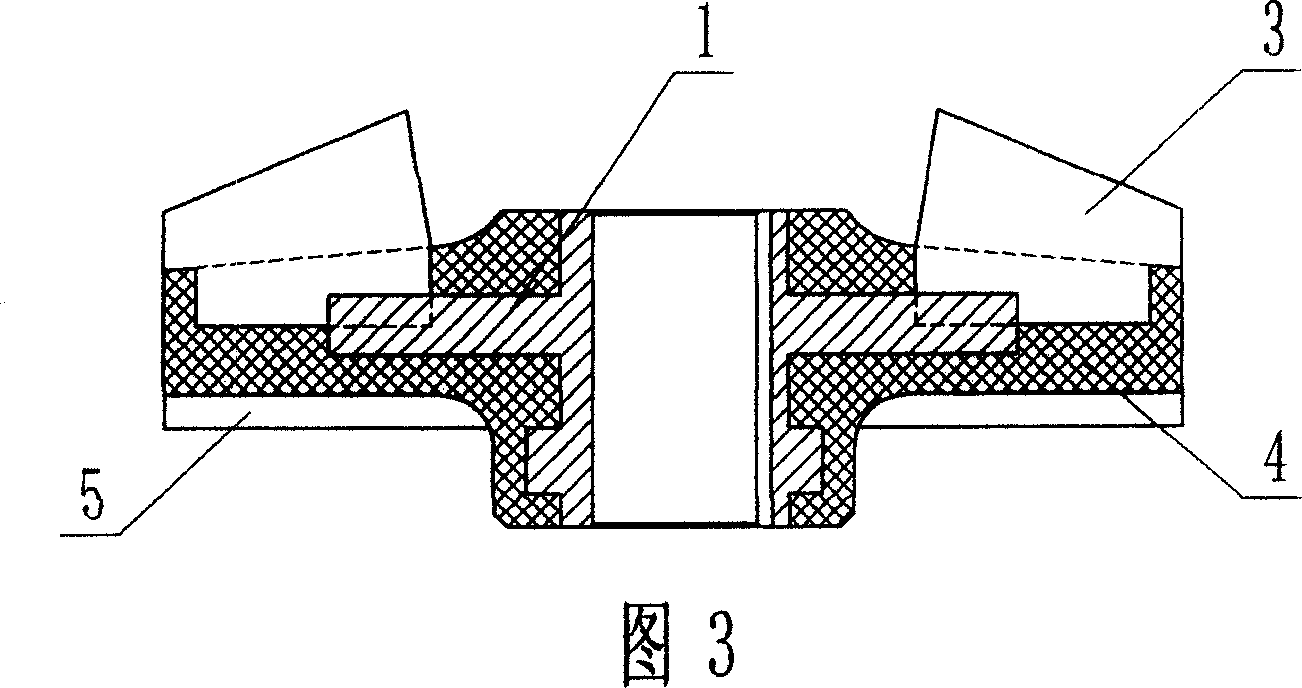

[0027] Embodiment 1: Referring to Figures 1-5, the impeller web core 1 is cast in metal, and the surface is processed with grooves 2 for embedding the blades according to the arc shape of the blades. Using wear-resistant ceramics (such as silicon carbide, Al 2 o 3 The impeller blade 3 is made of high-purity alumina, zirconia), wear-resistant alloy, and glass-ceramics with a content of more than 95%. The blade is inserted into the groove of the impeller core, put into the mold, and the hardenable resin 4 is poured on the peripheral surface of the web core of the metal impeller, so as to obtain the combined wear-resistant impeller with auxiliary blades 5 .

[0028] In addition, the surrounding surface of the metal core can also be injection molded plastics, or other organic polymer materials, and 30-90%wt mineral particles can be added in the polymer materials, or poplar-free fibers (such as ceramic fibers, glass fibers), to Improve the wear resistance of the web.

[0029] In...

Embodiment 2

[0031] Embodiment 2: Referring to Figures 6 and 7, the combined wear-resistant impeller of the present invention has a cast metal impeller web 8, and an additionally cast wear-resistant alloy blade 7 is fixed on the web by welding 9.

Embodiment 3

[0032] Embodiment 3: Referring to Figures 8, 9, and 10, the combined wear-resistant impeller of the present invention, its wear-resistant blade 10 can also be a blade part, that is, the web and part of the blade are made into one (leaving the most easily worn angle of attack position ), the wear-resistant blade 10 is welded or embedded in the default position of the blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com