Hydraulic coil upender

A rolling machine and hydraulic technology, applied in the field of rolling machines, can solve problems such as expensive maintenance costs, increased production costs, and damage to the turning plate, and achieve the effect of avoiding uneven force on the left and right

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

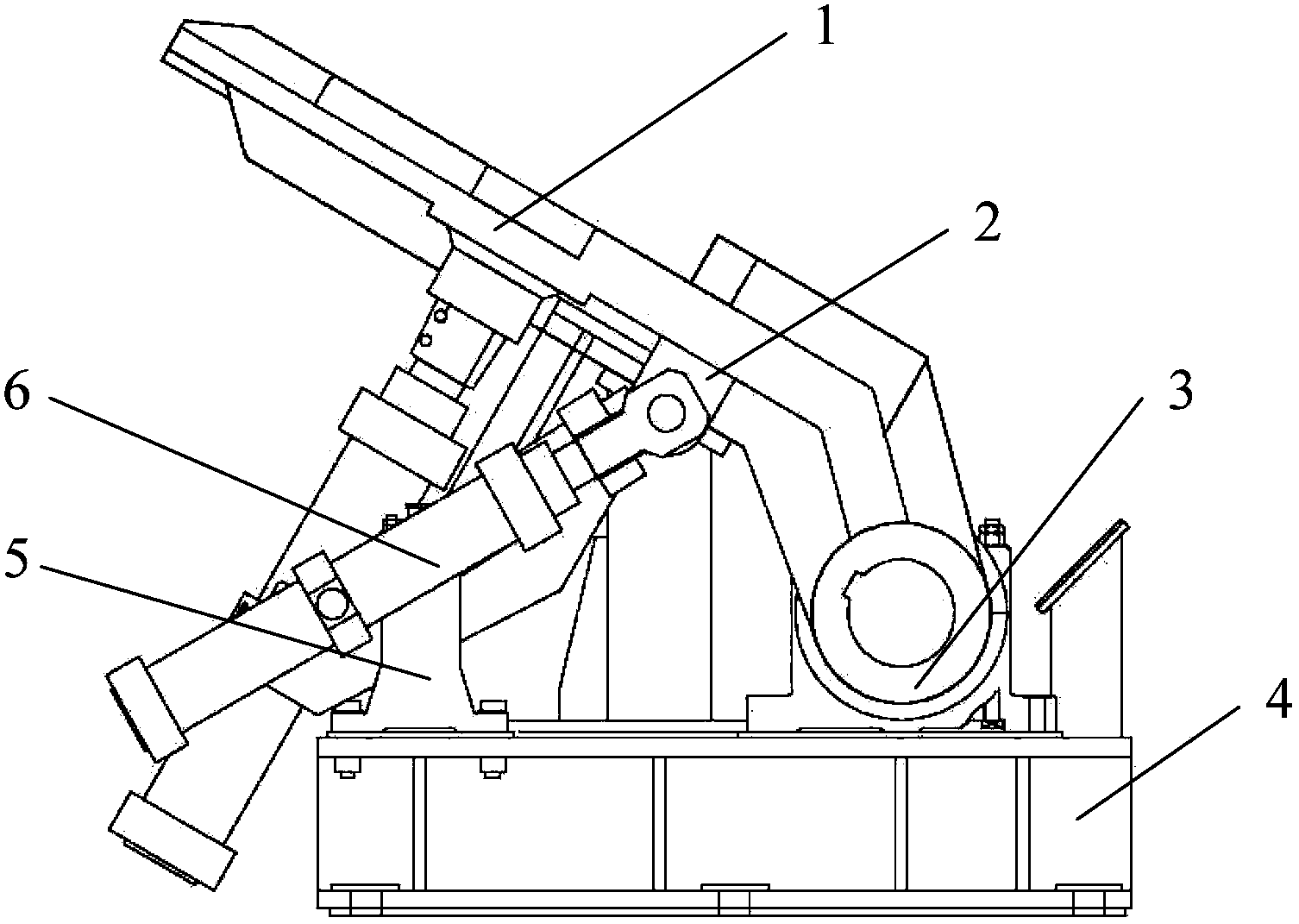

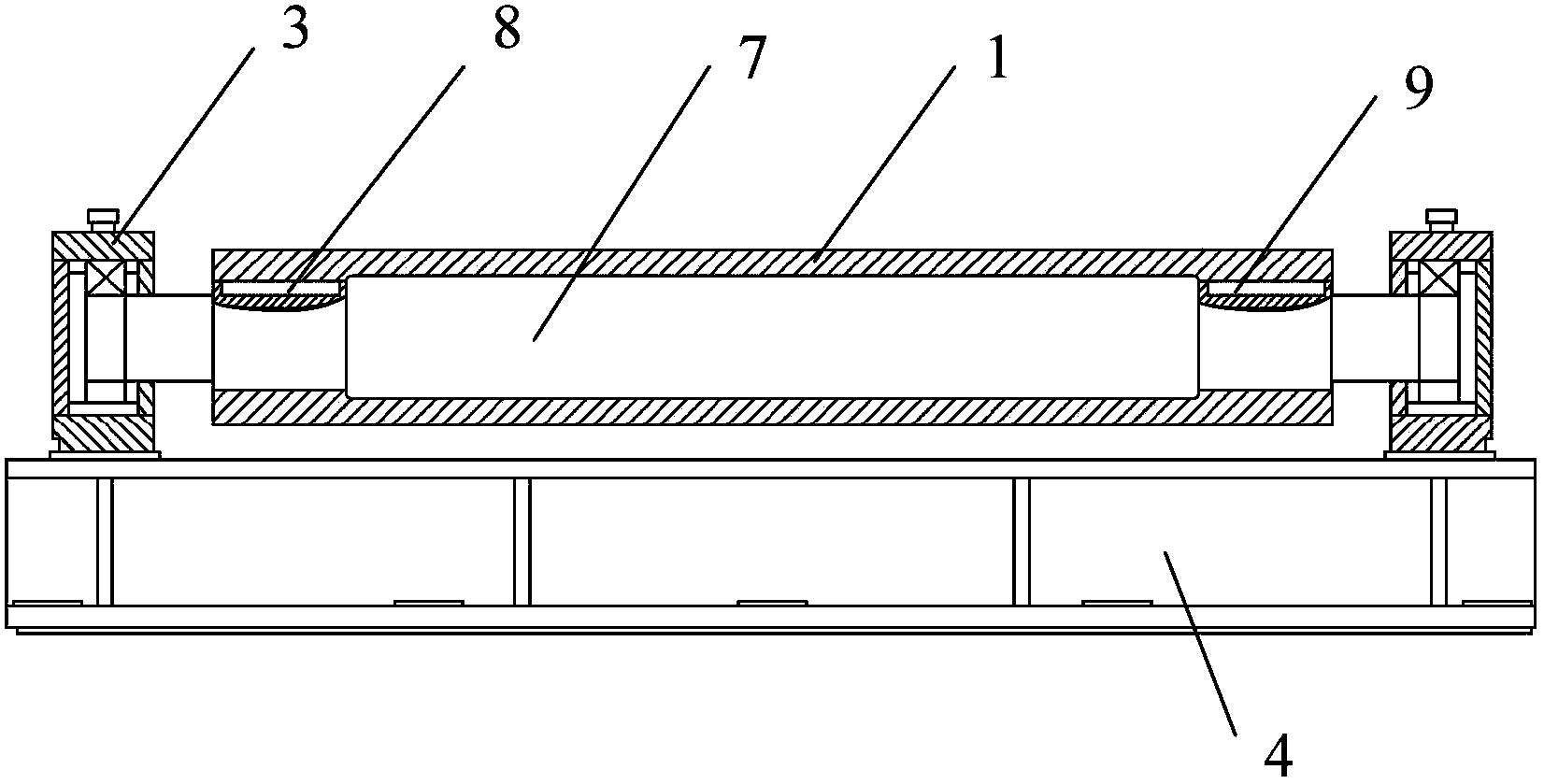

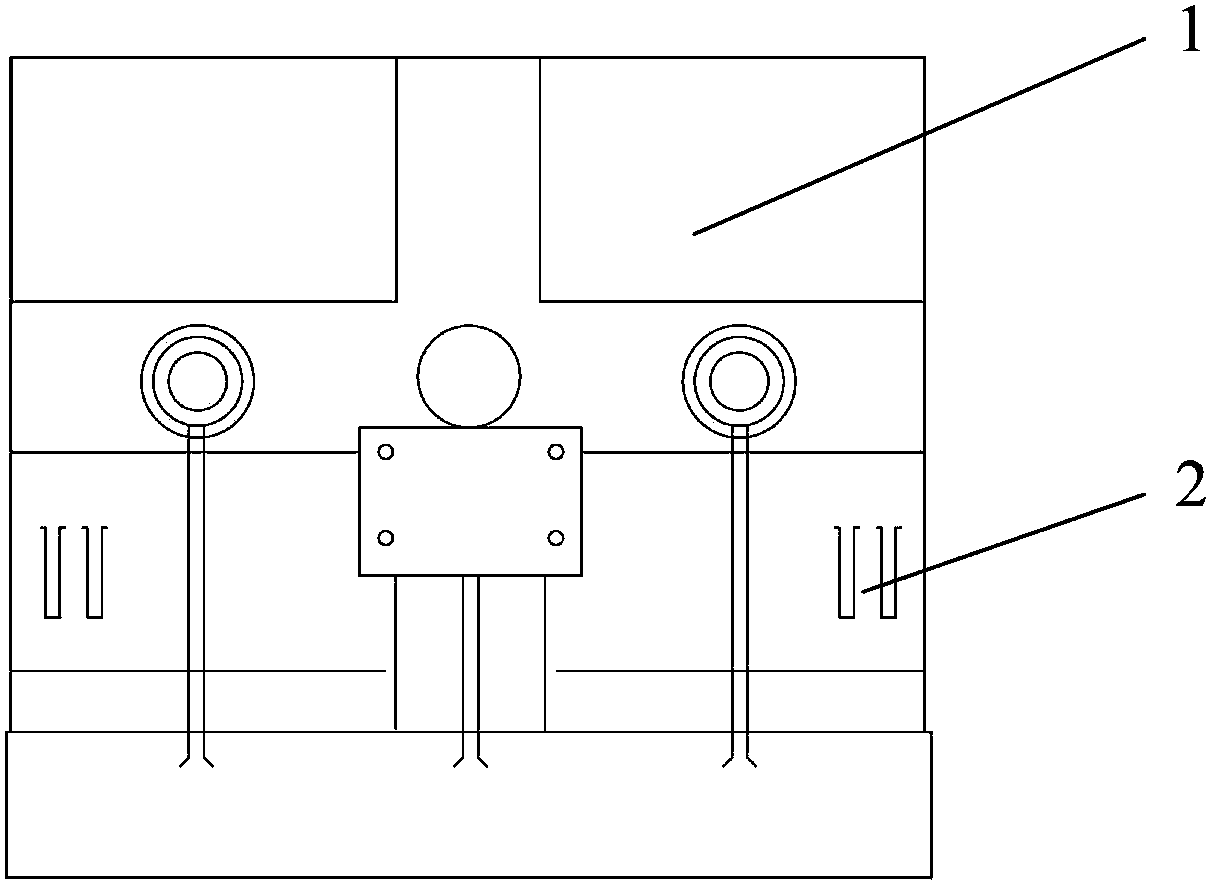

[0011] The following is attached Figure 1-3 The present invention is further described:

[0012] attached Figure 1-3 Middle: 1-flap, 2-hinge ear, 3-bearing seat, 4-base, 5-support seat, 6-hydraulic cylinder, 7-rotation shaft, 8-left button, 9-right button.

[0013] The present invention is provided with base 4, support seat 5, hydraulic cylinder 6, turnover plate 1, bearing seat 3, rotating shaft 7, left key 8, right key 9, support seat 5 and bearing seat 3 are arranged on base 4, bearing seat 3 It is arranged at both ends of the rotating shaft 7 and is hinged with the rotating shaft 7. The turning plate 1 is axially fixed with the rotating shaft 7 through the left key 8 and the right key 9. The lower bottom surface of the turning plate 1 is provided with hinge ears 2, and the hydraulic cylinder 6 is hinged The ear 2 is hinged with the flap 1, and the number of hydraulic cylinders 6 is 2 or more. In this embodiment, 2 are taken as an example. The number of hinged ears 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com