Splicing type swing rod of circular weaving machine

A spliced, circular loom technology, applied in circular looms, looms, textiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

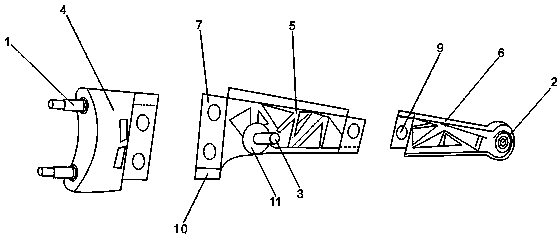

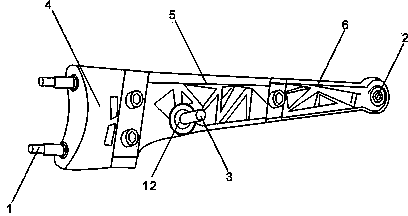

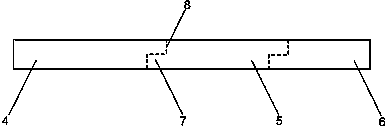

[0021] Such as figure 1 , figure 2 and image 3As shown, a circular loom splicing swing rod, the front end of which is provided with a swing rod slider axle 1 for installing the slider wheel, and the slider wheel is connected to the driving cam of the circular loom to obtain the swing power of the swing rod. The end of the swing rod is provided with a heald belt connecting bearing 2, and the middle and front part is provided with a rotating shaft 3 connected with the aluminum seat. The two ends of the rotating shaft 3 are respectively sleeved with aluminum seat bearings. The swing rod starts from the middle front to the end. The width gradually becomes smaller. The swing rod of the circular loom is a split structure, including three splicing sections, namely the front section 4, the middle section 5 and the end section 6. The axle 1 is located on the front section 4, and the heddle belt connection bearing 2 and the rotating shaft 3 are located on the end section 6 and the...

Embodiment 2

[0024] In the inter-segment connection structure, only the protruding laminated plates 7 at both ends of the middle section 5 are provided with side baffles 10, and the side baffles 10 are all arranged in pairs, and are located on both sides of the protruding laminated plates 7 on the middle section 5. . When the middle section 5 is connected with the front section 4 and the end section 6, only the protruding laminated plates 7 on the front section 4 and the end section 6 are inserted between the pair of side baffles 10 at both ends of the middle section 5, and then locked with bolts, The splicing between segments can be completed quickly. All the other are with embodiment 1.

Embodiment 3

[0026] The swing rod of the circular loom includes four splicing sections, which are the front section 4, the middle front section, the middle rear section and the end section 6. All the splicing sections are connected sequentially through the inter-segment connection structure, and the swing bar slider wheel shaft 1 is located on the front section 4. The heddle belt connecting bearing 2 and the rotating shaft 3 are respectively located on the end section 6 and the middle front section. The middle and rear sections are purely injection molded, and there are no moving parts on this section. Dividing the pendulum into four sections can further shorten the length of each section, thereby further reducing the manufacturing cost of each section. When the pendulum is partially damaged, the equipment recovery can be completed at a lower maintenance cost. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com