Warning light installation assembly of bestriding vehicle

A straddle-type vehicle and warning light technology, which is applied to bicycle accessories, transportation and packaging, optical signals, etc., can solve the problems of reducing the service life of the warning light, the appearance of the tail is not good, and the hidden danger of the warning light, and achieves a simple structure. Lightweight, reduce safety hazards, and reduce the effect of damage frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

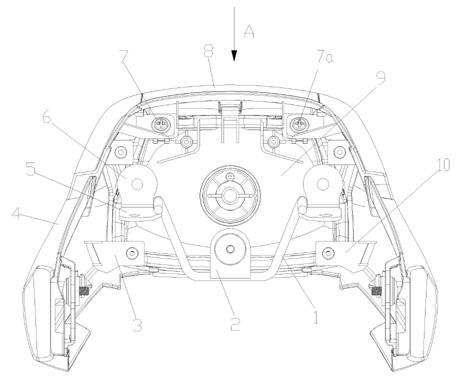

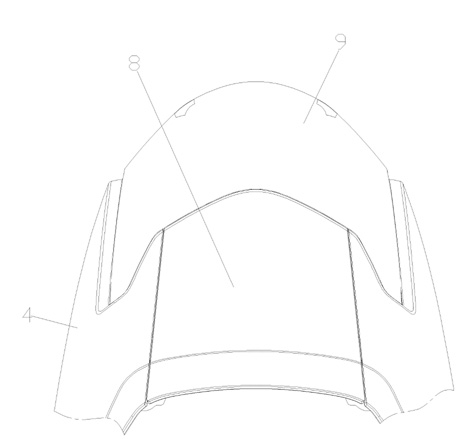

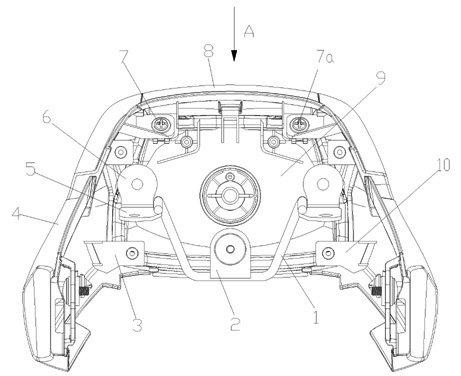

[0016] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Schematic diagram along the A direction, as shown in the figure: the straddle-type vehicle warning light installation assembly of this embodiment includes a warning light bracket 1 and a warning light shield 9, and the warning light shield 9 is fixed by the warning light bracket 1 On the straddle vehicle frame, the warning light bracket 1 is a U-shaped structure arranged horizontally and opening upwards, the bottom of the U-shaped structure is fixedly connected to the warning light shield 9, and the upper end of the U-shaped structure is fixedly connected to the warning light backwards. Shield 9 is fixedly connected to the straddle type vehicle frame forward.

[0017] In this embodiment, the motorcycle body 4 is symmetrically provided with two connection parts (the connection part 3 and the connection part 10 in the figure) connected with the warning light shield 9 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com