Method for making lead and tin alloy protruding point

A production method and lead-tin technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., can solve the problems of slow plating rate, long production cycle, and increased labor cost, avoiding bubbles, The effect of improving welding performance and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

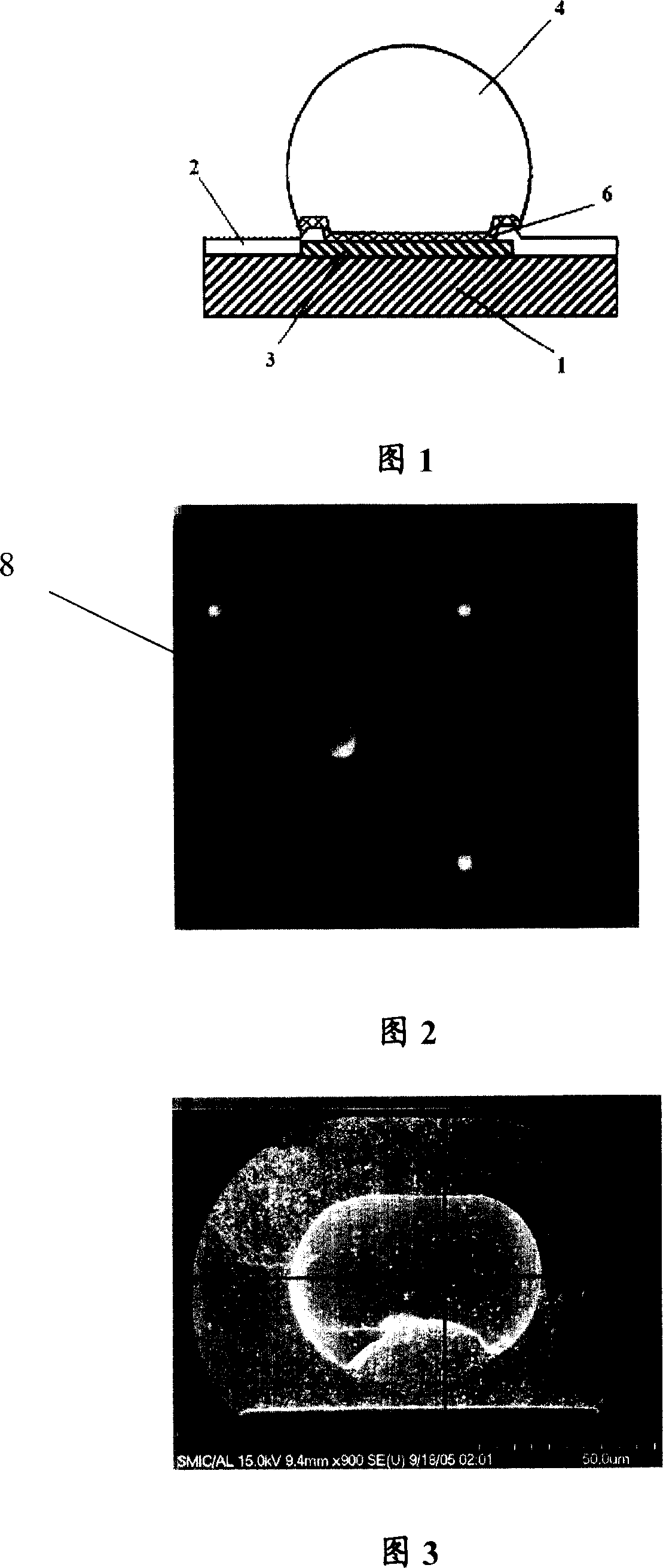

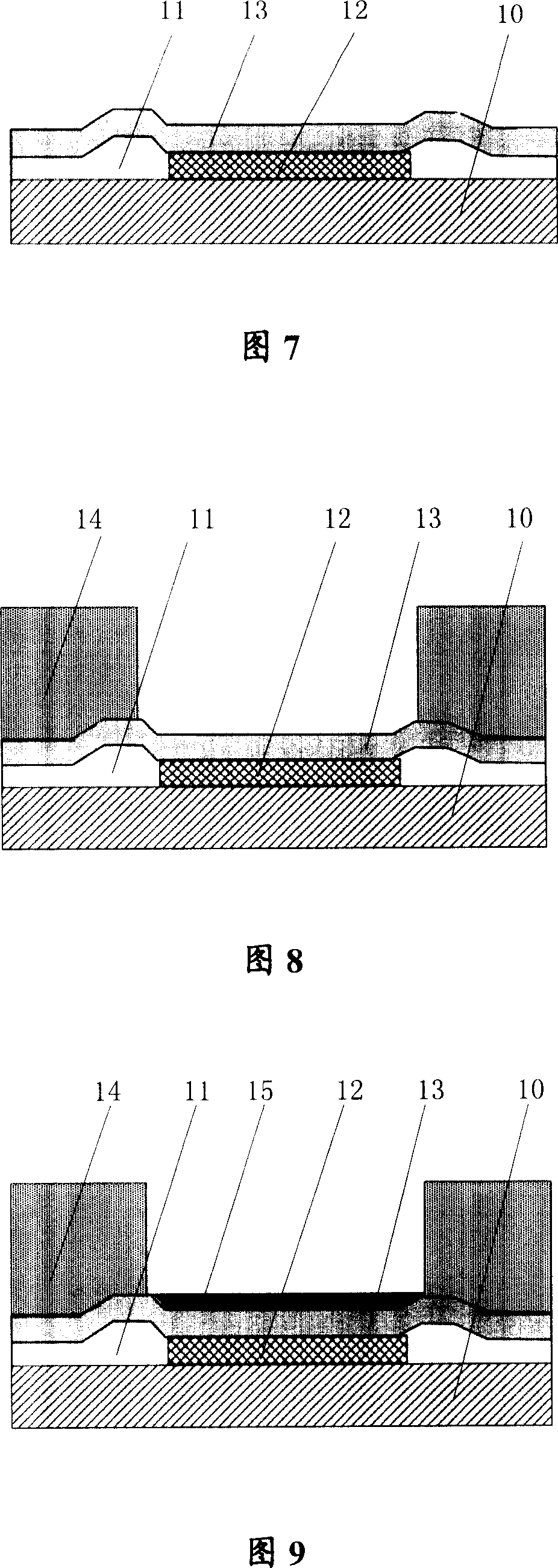

[0043] Aiming at the manufacturing method of the lead-tin alloy bump adopted in the present invention, a detailed description will be given below in conjunction with the accompanying drawings and embodiments.

[0044]In the prior art, materials such as titanium, titanium-tungsten alloy, copper, and nickel are usually selected as the under-bump metal material in the solder bump process, and metal nickel is more commonly used when depositing lead-tin alloy bumps by electroplating.

[0045] When adopting lead-tin alloy as bump solder, and adopting the method for electroplating to deposit lead-tin alloy bump, usually adopt the electroplating solution of methanesulfonic acid system, lead ion concentration (Pb 2+ ) is 40 to 60g / L, tin ions (Sn 2+ ) concentration is 5 to 10g / L, methanesulfonic acid is used as the complexing agent in the solution, and the concentration is 200 to 300g / L. When electroplating lead-tin alloy solder, the current density is 3A / dm 2 up to 10A / dm 2 , the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com